Biological enhancer for treating livestock and poultry breeding wastewater and preparation method thereof

A technology of livestock and poultry breeding wastewater and bioaugmentation, applied in the field of biological environmental protection, can solve the problems of lack of some trace elements, lack of pertinence in treatment, high cellulose content, etc., to improve COD removal rate, improve microbial activity, and efficiently degrade nutrients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

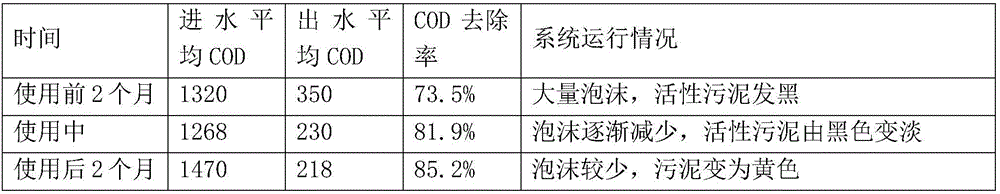

Embodiment 1

[0031] Sewage treatment project of a cattle farm, the treatment water volume is 150m 3 / d, the sewage treatment process is as follows: all the feces and wastewater from the cattle farm enter the regulating tank, and after passing through the solid-liquid separator in it, the clear liquid part enters the biogas fermentation tank for anaerobic fermentation through the lift pump, and the fermented biogas slurry is automatically After flowing into the contact oxidation tank for aerobic treatment, it can reach the standard discharge after being treated by air flotation. Among them, the influent COD of the aerobic unit is 1400mg / L, and the aerobic treatment adopts the contact oxidation method.

[0032] Configure biological enhancer, the specific method is as follows:

[0033] 1) Take the following ingredients as solid powder (40-60 mesh), and the parts by weight are: 2 parts of Bacillus licheniformis, 1 part of Candida tropicalis, 0.7 part of cellulase, 0.1 part of iron sulfate, ph...

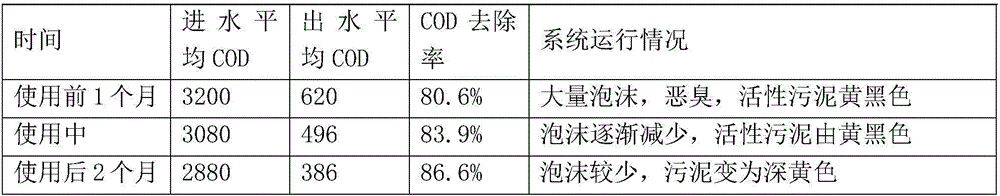

Embodiment 2

[0043] Sewage treatment project of a pig farm, the treated water volume is 60m 3 / d, the sewage treatment process is: the sewage passes through the sedimentation tank to complete the solid-liquid separation through natural settlement, and the supernatant is lifted by the submersible pump into the anaerobic tank for reaction, then flows into the anoxic tank to continue the reaction, and then flows into the contact oxidation tank for further treatment Aerobic treatment, the waste water after aerobic treatment is reacted in the flocculation sedimentation tank, and the supernatant can be discharged up to the standard. Hydrolysis and acidification influent COD3000mg / L.

[0044] Configure biological enhancer, the specific method is as follows:

[0045] 1) Take the following ingredients as solid powder (40-60 mesh), and its parts by weight are: 6 parts of Bacillus licheniformis, 3 parts of Candida tropicalis, 0.2 part of cellulase, 0.3 part of ferric chloride, 0.7 part of ammonium ...

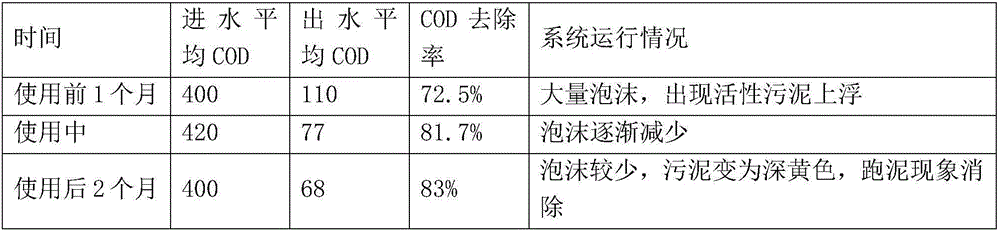

Embodiment 3

[0055] A chicken farm sewage treatment project, the treatment water volume is 60m 3 / d, the sewage treatment process is as follows: the sewage first enters the buffer pool, the sewage in the buffer pool passes through the solid-liquid separator, and then the clear liquid flows into the adjustment tank, the sewage in the adjustment pool is lifted by the submersible pump into the biogas fermentation tank, and the fermented biogas slurry enters the sedimentation tank Natural settlement is carried out, and the supernatant is lifted into the CASS pool by a pump for aerobic treatment, and the effluent from the CASS pool is treated by a sand filter tank and an ultraviolet sterilizer to meet the standard discharge. CASS pool influent COD400mg / L.

[0056] Configure biological enhancer, the specific method is as follows:

[0057] 1) Take the following ingredients as solid powder (40-60 mesh), and the parts by weight are: 3 parts of Bacillus licheniformis, 2 parts of Candida tropicalis,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com