Preparation method of tungsten diselenide nanosheet

A technology of tungsten diselenide nanometer and tungsten diselenide, which is applied in the direction of binary selenium/tellurium compound, nanotechnology, metal selenide/telluride, etc., which can solve the application limitation of WSe2, unfavorable large-scale industrial production, and reaction atmosphere Require high-level issues to achieve the effect of green raw materials, fewer layers, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Dissolve 0.1513g of sodium borohydride in 50ml of N,N-dimethylformamide and mix evenly, add 0.3632g of selenium powder and stir until completely dissolved, then add 0.6597g of sodium tungstate to prepare a mixed solution;

[0028] Step 2: transfer the mixed solution obtained in step 1 to a polytetrafluoroethylene reactor, and react at a temperature of 200° C. for 48 hours;

[0029] Step 3: After the temperature of the reaction kettle in step 2 was naturally cooled to room temperature, the black product was collected by suction filtration, washed with deionized water and ethanol respectively, and freeze-dried for 24 hours to obtain tungsten diselenide nanosheets.

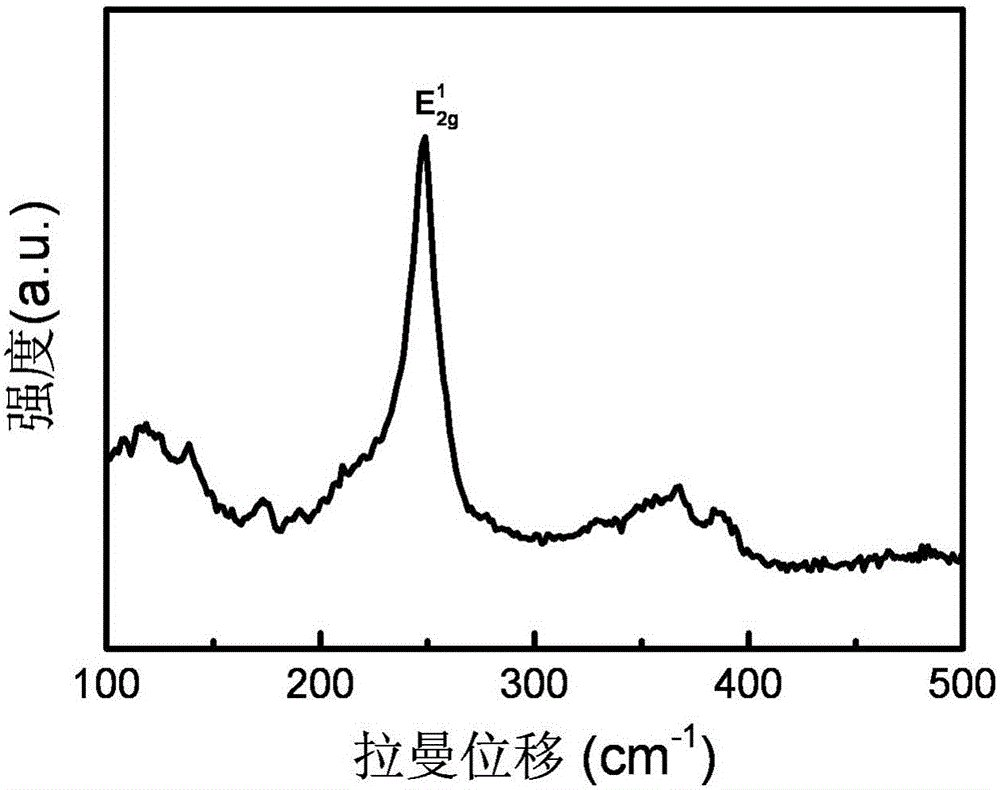

[0030] figure 1 It is the Raman spectrogram of the product after reacting the reactant of Example 1 at 200°C for 48 hours. As can be seen from the figure, at 249cm -1 WSe 2 Obvious Raman characteristic peak E 1 2g .

Embodiment 2

[0032] Step 1: Dissolve 0.1135g of sodium borohydride in 50ml of N,N-dimethylformamide and mix evenly, add 0.3395g of selenium powder and stir until completely dissolved, then add 0.6597g of sodium tungstate to prepare a mixed solution;

[0033] Step 2: transfer the mixed solution obtained in step 1 to a polytetrafluoroethylene reactor, and react at a temperature of 220° C. for 36 hours;

[0034] Step 3: After the temperature of the reaction kettle in step 2 was naturally cooled to room temperature, the black product was collected by suction filtration, washed with deionized water and ethanol respectively, and freeze-dried for 24 hours to obtain tungsten diselenide nanosheets.

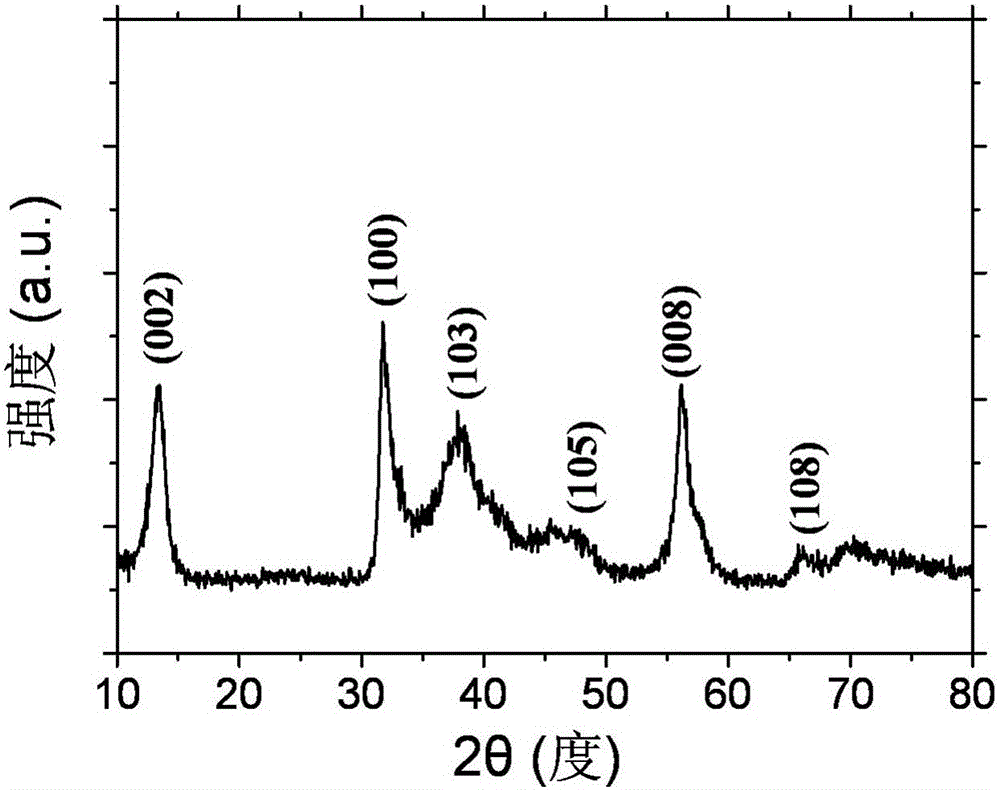

[0035] figure 2 In order to implement the X-ray diffraction (XRD) pattern of the product after the reaction of the 2 reactants for 36 hours at 220°C, it can be seen from the figure that the product is a tungsten diselenide nanosheet (WSe) with better crystallization. 2 ), without any impurity.

[0036...

Embodiment 3

[0038] Step 1: Dissolve 0.1135g of sodium borohydride in 80ml of N,N-dimethylformamide and mix evenly, add 0.6317g of selenium powder and stir until completely dissolved, then add 1.3194g of sodium tungstate to prepare a mixed solution;

[0039] Step 2: transfer the mixed solution obtained in step 1 to a polytetrafluoroethylene reactor, and react at a temperature of 240° C. for 24 hours;

[0040] Step 3: After the temperature of the reaction kettle in step 2 was naturally cooled to room temperature, the black product was collected by suction filtration, washed with deionized water and ethanol respectively, and freeze-dried for 24 hours to obtain tungsten diselenide nanosheets.

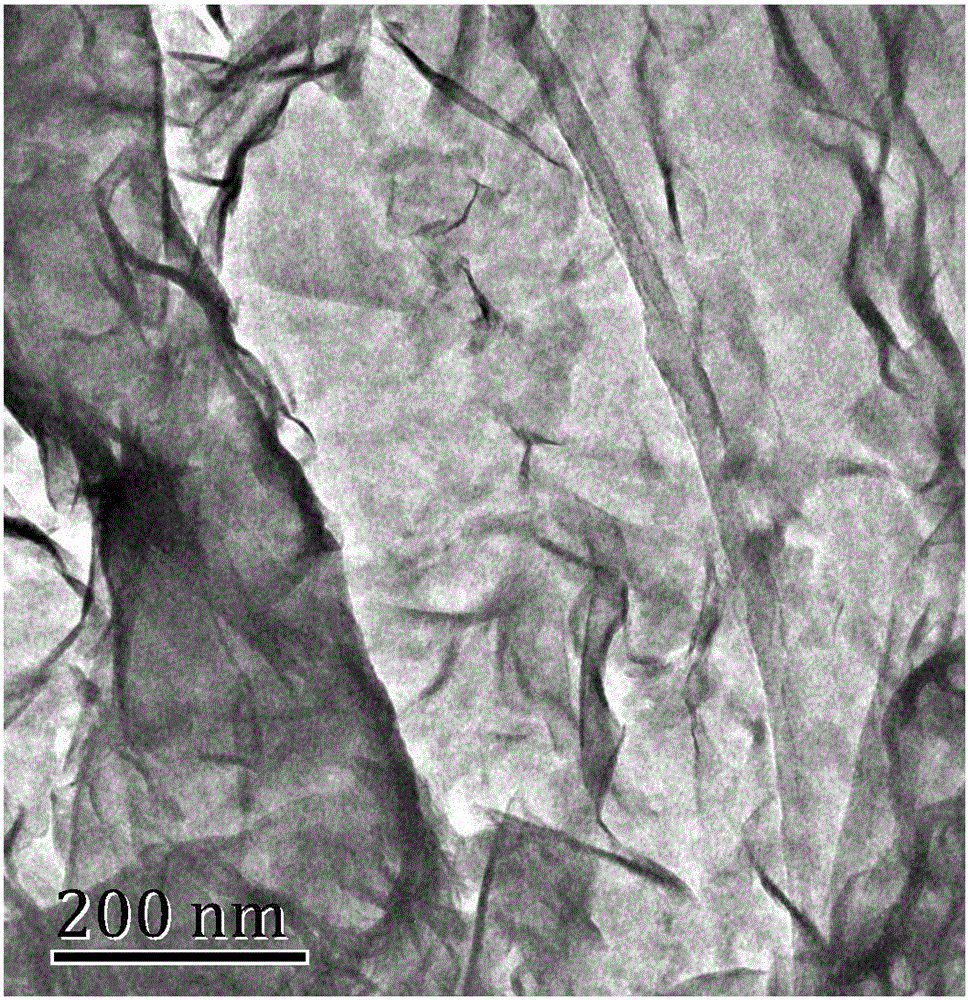

[0041] Figure 4 It is a transmission electron microscope (TEM) figure of the product after reacting the reactant of Example 3 under the condition of 240° C. for 24 hours. As can be seen from the figure, the product is WSe similar to graphene 2 nanoflakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com