A water-based hydrophobic optical coating and a laser holographic anti-counterfeiting hot stamping film made of the coating

An optical coating and laser holography technology, applied in the field of optical coatings, can solve the problems of solvent volatilization, low glass transition temperature, high brittleness, etc., to achieve enhanced water resistance and anti-fouling performance, large specific surface area, and improved wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

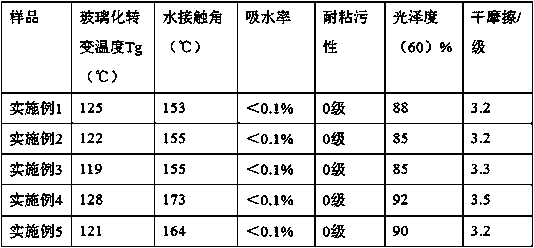

Examples

Embodiment 1

[0037] (1) Preparation of polyacrylate-organosiloxane graft copolymer emulsion A:

[0038]In a four-necked flask with a condenser, a dropping device, an electric stirrer, and a thermometer, add 52.5g of deionized water and 5.5g of silicon carbide with a particle diameter of 10nm, and stir for 60 minutes at a speed of 6000 revolutions per minute, until Uniformly disperse to obtain a microemulsion; add 100 g of deionized water to the above-mentioned flask, then add 26.5 g of methyl methacrylate, 22.5 g of amino acrylate, and dimethacrylic acid dropwise to the beaker under high-speed stirring. 24.8g ethylene glycol ester, 20g butyl methacrylate, 8.5g HS-G217 vinyl silicone oil, 0.2g sodium bicarbonate, 0.8g sodium dodecylbenzenesulfonate, 2.5g polyoxyethylene nonylphenol ether, Then heat and stir, condense and reflux, and heat up to 75 ° C to form a stable microemulsion; 10 g of potassium persulfate aqueous solution with a mass fraction of 10% is evenly added dropwise to the abov...

Embodiment 2

[0044] (1) Preparation of polyacrylate-organosiloxane graft copolymer emulsion A:

[0045] Add 50g of deionized water and 6g of silicon carbide with a particle size of 12nm into a four-necked flask equipped with a condenser, dropping device, electric stirrer, and thermometer, and stir for 30 minutes at a speed of 6,000 rpm until uniformly dispersed. , to obtain a microemulsion; add deionized water 100g in the above-mentioned flask, then add dropwise methyl methacrylate 28.5g, amino acrylate 25g, ethylene glycol dimethacrylate in the beaker under the condition of high-speed stirring 20g ester, 22.5g butyl methacrylate, 8g HS-G217 vinyl silicone oil, 0.4g sodium bicarbonate, 0.5g sodium dodecylbenzenesulfonate, 2g polyoxyethylene nonylphenol ether, then heated and stirred, condensed Reflux and heat up to 80°C until a stable microemulsion is formed; 12g of potassium persulfate aqueous solution with a mass fraction of 10% is evenly added dropwise to the above microemulsion for 3 h...

Embodiment 3

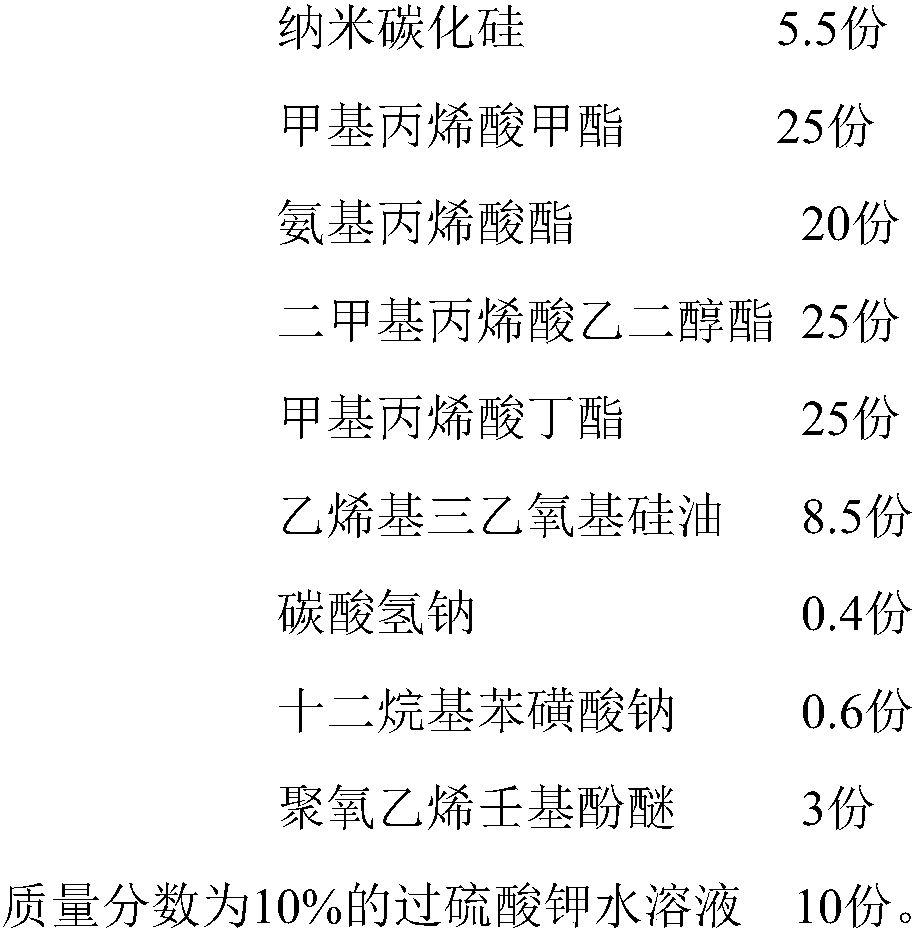

[0051] (1) Preparation of polyacrylate-organosiloxane graft copolymer emulsion A:

[0052] Add 60g of deionized water and 5g of silicon carbide with a particle size of 10nm into a four-necked flask equipped with a condenser, dropping device, electric stirring, and thermometer, and stir for 60 minutes at a speed of 6000 rpm until uniformly dispersed , to obtain a microemulsion; add deionized water 100g in the above-mentioned flask, then add dropwise methyl methacrylate 25g, amino acrylate 20g, ethylene glycol dimethacrylate in the beaker under the condition of high-speed stirring 30g, 25g butyl methacrylate, 10g vinyl triethoxy silicone oil, 0.5g sodium bicarbonate, 1g sodium dodecylbenzenesulfonate, 3g polyoxyethylene nonylphenol ether, then heated and stirred, condensed and refluxed, Raise the temperature to 80°C until a stable microemulsion is formed; 11.5g of an aqueous solution of potassium persulfate with a mass fraction of 10% is evenly added dropwise to the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com