Preparation method of functional biodegradable nano particle based on polyamino acid

A polyamino acid and nanoparticle technology, which is applied in medical preparations with non-active ingredients, medical preparations containing active ingredients, drug combinations, etc., can solve the problems of low stability of nano-microspheres and difficult surface functionalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment one initiator vitamin E amino (VE-NH 2 )Synthesis

[0037] (1) Preparation of intermediate VE-4-NC: Under nitrogen atmosphere, dichloromethane (30 mL) solution of p-nitrophenyl chloroformate (4-NC, 1.98 g, 9.8 mmol) was heated at 0°C It was added dropwise to a solution of vitamin E (VE, 2.12 g, 4.9 mmol) and pyridine (1.98 mL, 24.5 mmol) in dichloromethane (10 mL) at a rate of 5 seconds. After the dropwise addition was completed, it was transferred to a 30° C. oil bath to react for 24 hours. After the reaction, the by-product pyridinium salt was removed by filtration, and the filtrate was spin-dried by a rotary evaporator to obtain a light yellow viscous crude product of VE-4-NC. Then dissolve the crude product with petroleum ether (b.p: 60-90 ℃), centrifuge to remove impurities, rotary evaporate, and finally vacuum-dry to obtain the yellow viscous oily product VE-4-NC, with a yield of 93.4%;

[0038] (2) Initiator vitamin E amino (VE-NH 2 ) preparation: ...

Embodiment 2

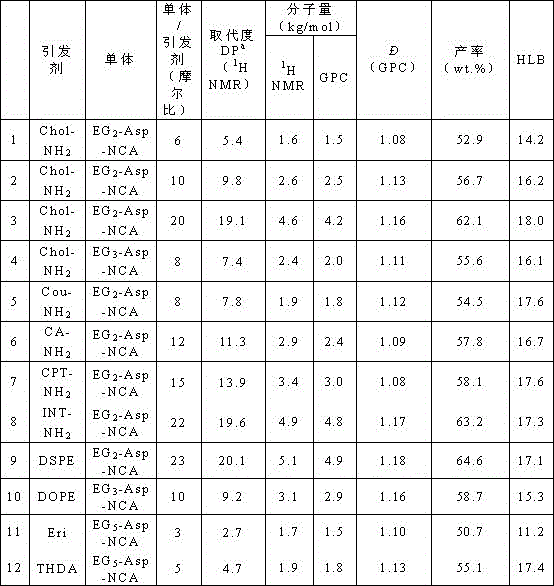

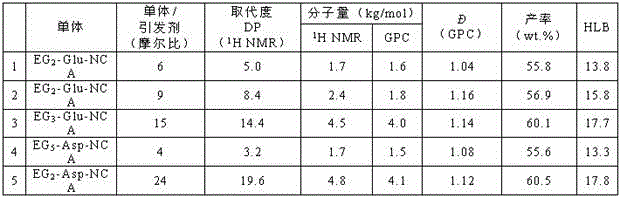

[0041] Example 2 Vitamin E-poly(γ-diethylene glycol monomethyl ether-L-glutamic acid) (VE-poly(EG 2 -Glu)) synthesis

[0042] Vitamin E Amino VE-NH 2 (1.16 g, 2.25 mmol) was dissolved in 37 mL of dichloromethane solvent and placed in a closed reactor. Under nitrogen atmosphere, γ-diethylene glycol monomethyl ether-L-glutamic acid-N-carboxy internal acid anhydride (EG 2 -Glu-NCA) (3.71 g, 13.50 mmol) monomer in dichloromethane (37 mL) was quickly added to the initiator and reacted at 25 °C for 12 hours. The reaction process was monitored by Fourier transform infrared spectroscopy. After the reaction, the reaction solution was concentrated by rotary evaporation to about 18 ml, precipitated with glacial ether, and centrifuged at low temperature (-5°C, 5000 rpm) to collect the precipitate. Finally, it was washed three times with glacial ether and dried in vacuum for 48 hours to obtain a pale yellow product with a yield of 55.8%.

[0043] VE-poly(EG 2 -Glu) NMR characterizati...

Embodiment 3

[0051] Example Three Using VE-poly(EG x -Glu) n Preparation of PLGA Nanoparticles for Polymeric Surfactants

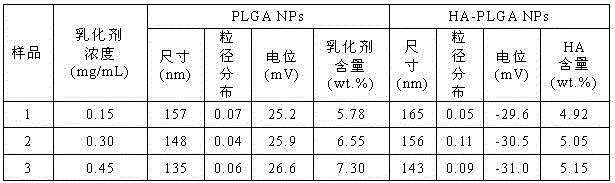

[0052] Preparation of PLGA nanoparticles (PLGA NPs): with VE-poly(EG 2 -Glu) 5 As a polymer surfactant as an example, 0.9 mL of PLGA in acetone (10 mg / mL) was added dropwise to 9 mL of VE-poly(EG 2 -Glu) 5 In an aqueous solution (0.45 mg / mL), stir at room temperature for 6 h to evaporate acetone, then centrifuge (12000 rpm, 10 min, 4 ℃; SorvallBiofuge Stratos, Thermo Scientific) to collect nanoparticles, and wash once with secondary water to remove free emulsified agent, prepared surface containing VE-poly (EG 2 -Glu) 5 PLGA nanoparticles. The particle size and particle size distribution of nanoparticles can be measured by dynamic light scattering to be 135 nm and 0.06, respectively. The surface of nanoparticles contains VE-poly(EG 2 -Glu) 5 The polyamino acid chain segment can be confirmed by observing the appearance of N peak through X-ray photoelectron spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com