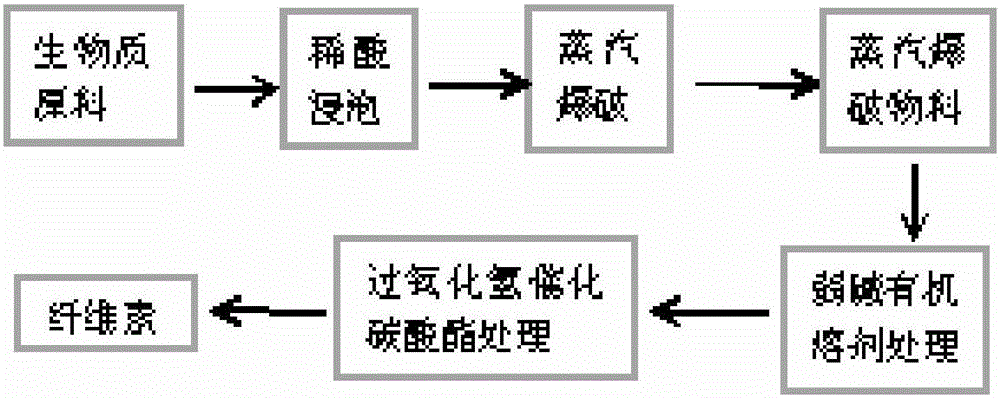

Process for cleanly preparing cellulose by utilizing lignocellulose

A wood fiber and cellulose technology, applied in fiber raw materials, fiber raw material treatment, pulping with organic solvents, etc., can solve problems such as difficult water treatment and serious environmental pollution, and achieve the effect of improving extraction yield and broad development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

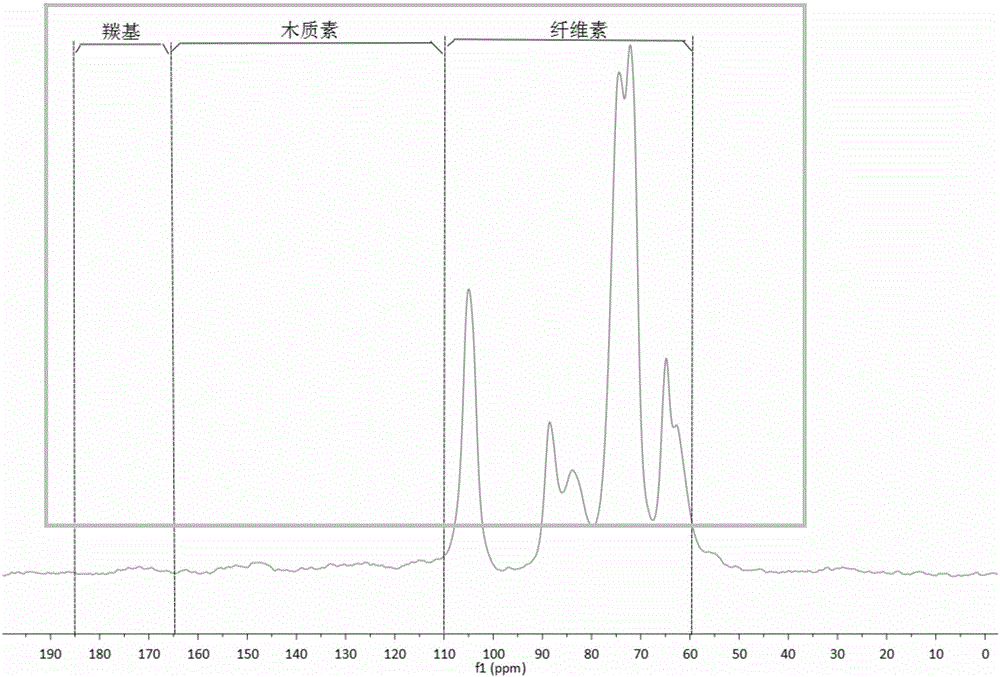

Embodiment 1

[0027] Use corncobs as raw materials to prepare cellulose. The specific method is: take 300g of corncobs that are crushed to a diameter of 1cm, add 500mL of dilute sulfuric acid solution with a mass fraction of 0.2%, place at 25°C for 10h, and press filter to discharge the unabsorbed acid solution Continue to reuse. Pour the acid-pretreated corn cobs into the steam explosion machine, and introduce a steam pressure of 1.0 MPa. The corn cobs stay in the retainer cylinder for 10 minutes, reduce the pressure to an atmospheric pressure, wash with water to obtain steam explosion materials, and dry them. Take 10g of dry steam explosion material, add 90mL of ethanol, 10mL of water, add 0.2g of sodium hydroxide, heat up to 200°C in an autoclave, stir at 300rmp, and react for 1h. After cooling to room temperature, filter and wash with water, and dry at 40°C. Take 5g of the dried material and add it to 50mL of dimethyl carbonate, add 17g of hydrogen peroxide, treat at 60°C for 2h, filte...

Embodiment 2

[0029] Prepare cellulose with straw as raw material, the specific method is: take 300g of straw, wash with water to remove dust and impurities, add 1.2L of oxalic acid solution with a mass fraction of 0.3%, place it at 80°C for 1 hour, press filter to discharge the unabsorbed acid solution Continue to reuse. Pour the acid-pretreated straw into the steam explosion machine, and introduce a steam pressure of 0.8MPa. The straw stays in the retainer cylinder for 10 minutes, and the pressure is reduced to an atmospheric pressure. The steam-exploded material is obtained by washing with water, and dried. Take 10g of dry steam explosion material, add 40mL of 1,4-dioxane, add 60mL of water, add 0.04g of ammonium hydroxide, heat up to 180°C in an autoclave, stir at 300rmp, and react for 5h. After cooling to room temperature, filter and dry at 50°C. Take 5g of the dried material and add it to 80mL of diethyl carbonate, add 25.5g of hydrogen peroxide, treat at 90°C for 0.5h, filter, wash ...

Embodiment 3

[0031] Use bagasse as raw material to prepare cellulose. The specific method is: take 300g of bagasse, wash it with water to remove impurities, add 1L of phosphoric acid solution with a mass fraction of 1%, place it at 40°C for 6 hours, press filter to discharge the unabsorbed acid solution and continue to reuse . Pour the acid-pretreated bagasse into the steam explosion machine, and introduce a steam pressure of 2.0 MPa. The straw stays in the retainer cylinder for 40 minutes, and the pressure is reduced to an atmospheric pressure. The steam explosion material is obtained by washing with water, and dried. Take 15g of dry steam explosion material, add 30mL of formic acid, 20mL of water, and 0.01g of potassium hydroxide, heat up to 280°C in a high-pressure reactor, stir at 300rmp, and react for 3h. After cooling to room temperature, filter and dry at 50°C. Take 5g of the dried material and add it to 500mL of cyclohexyl carbonate, add 51g of hydrogen peroxide, treat at 50°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com