Preparation method of alkaline anion exchange membrane

A basic anion, exchange membrane technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of weak cross-linking ability, reduce the conductivity of anion exchange membrane, etc., to improve mechanical properties , Improve physical and chemical stability, good thermal stability and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment provides a kind of polymerized ionic liquid modified graphene oxide, and its preparation method comprises the following steps:

[0024] (1) 9.41g (0.10mol), 19.87gγ-chloropropyltrimethoxysilane (0.10mol) and 0.09g benzoquinone were added in 100ml anhydrous acetonitrile, and reflux reaction was carried out at 50°C for 30 hours; 5 times, drying after rotary evaporation to obtain polymeric ionic liquid

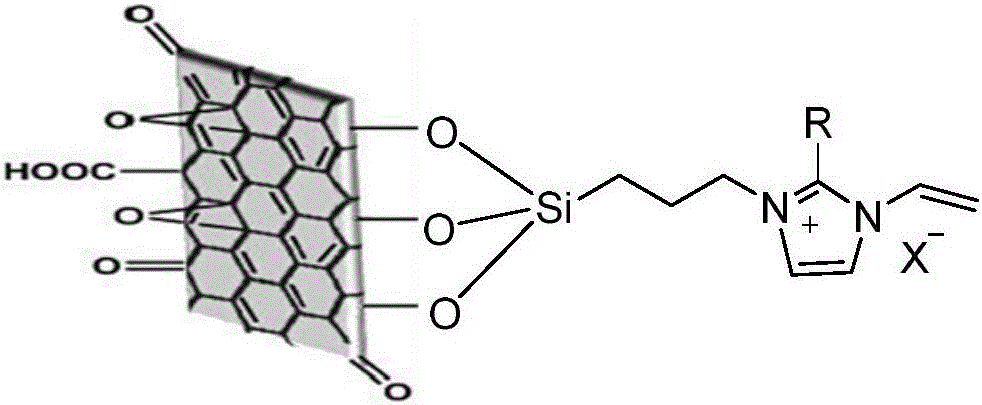

[0025] (2) Add the polymerized ionic liquid obtained in 2.0g step (1) and 2.0g graphene oxide to 100ml ethanol, add a small amount of ammonia water to adjust the mixed solution pH=2, filter after reacting at room temperature for 40 hours, and use After washing with water and ethanol for 3 times, and drying after rotary evaporation, the polymerized ionic liquid modified graphene oxide is obtained, and its chemical structure general formula is

[0026] Refer to Example 1 for the synthesis method of polymerized ionic liquid modified graphene oxid...

Embodiment 2

[0028] The present embodiment provides a kind of preparation method of basic anion exchange membrane, and it comprises the following steps:

[0029] (1) take Mix 0.006g, styrene 0.45g, acrylonitrile 0.14g, benzoin ethyl ether 0.006g, and crosslinking agent 0.012g, mix it under ultrasonic vibration for 3 minutes until uniform, apply it on the mold, and irradiate it with ultraviolet light with a wavelength of 250nm 30min, in situ polymerization to obtain a polymer film;

[0030] (2) Then soak the anion exchange membrane in 60°C, 1M KOH solution for 24 hours to convert anions into OH - , the OH obtained in this example - The ion conductivity of the type anion exchange membrane at room temperature is 1.10×10 -2 S cm -1 , the ionic conductivity at 90°C is 3.05×10 -2 S cm -1 , the tensile strength is 13.33Mpa, the Young's modulus is 393.57Mpa, and the elongation at break is 4.35%.

Embodiment 3

[0032] This example provides a method for preparing a basic anion exchange membrane, the preparation steps of which are basically the same as in Example 2, the difference is that the ratio of raw materials is different, specifically: styrene 0.44g, acrylonitrile 0.15g, polymer Type Ionic Liquid Modified Graphene Oxide 0.012g, benzoin ethyl ether 0.01g, crosslinking agent 0.02g, the OH obtained in this embodiment - The ion conductivity of the type anion exchange membrane at room temperature is 1.50×10 -2 S cm -1 , the ionic conductivity at 90°C is 3.55×10 -2 S cm -1 , the tensile strength is 16.67Mpa, the Young's modulus is 445.08Mpa, and the elongation at break is 4.54%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com