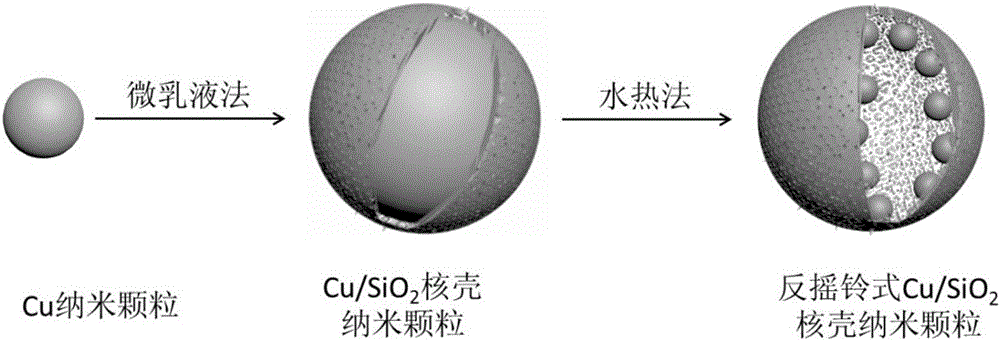

High-dispersity hollow anti-bell ringing type copper/silicon dioxide core-shell nanoparticle and preparation method thereof

A copper nanoparticle and silicon dioxide technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for material and surface science, can solve the problems of cumbersome and low material utilization, achieve low corrosiveness and simple methods The effect of rapid, readily available synthetic raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

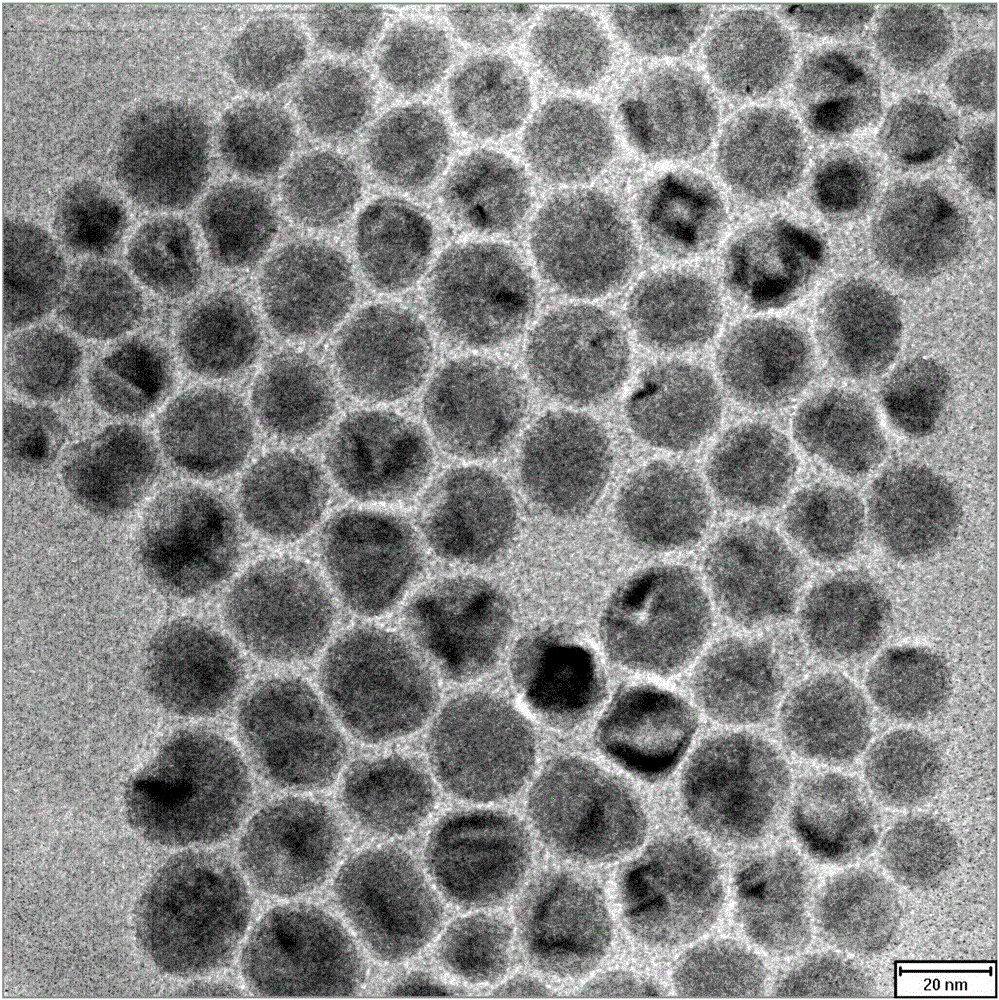

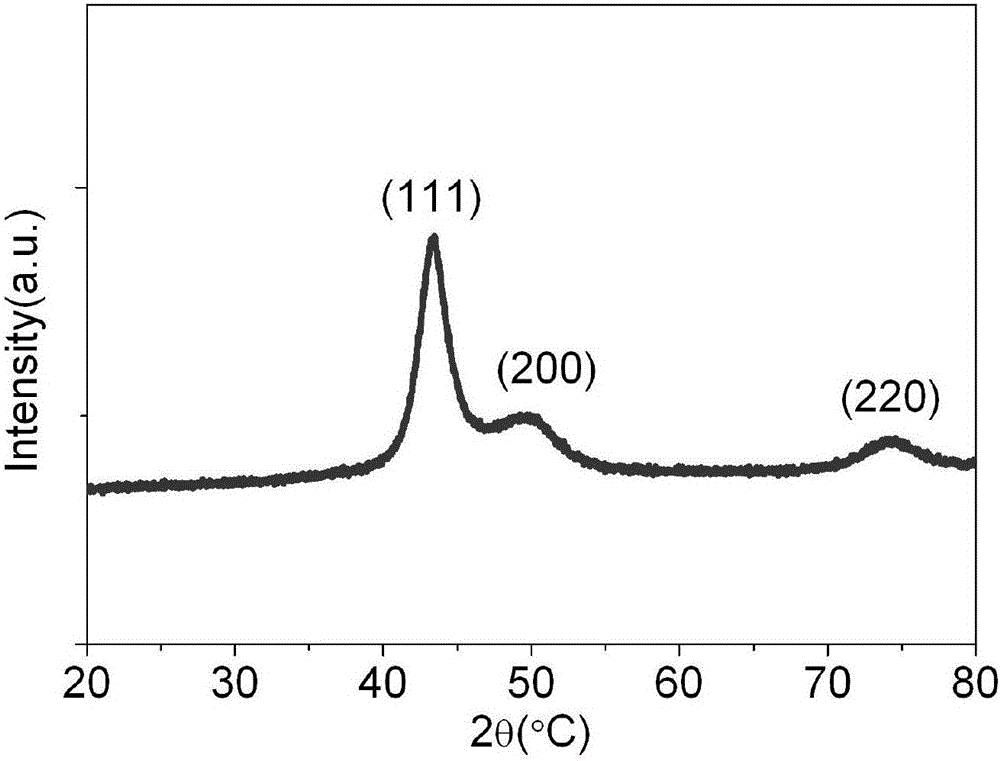

[0029] (1) Weigh 0.8376g of copper acetylacetonate and add it to a 150mL round bottom flask with a magnet. An additional 14.2275 g of oleylamine was added. Under the protection of nitrogen, the temperature was gradually raised to 120°C and kept for 10 minutes to remove impurities such as water in the system. Then, when the temperature was raised to 200° C. at a heating rate of 20° C. / min, 1.4228 g of trioctylphosphine was added. Continue heating to 220°C and keep it for 2h, then cool down to room temperature under the protection of nitrogen. After adding 30mL ethanol solution, centrifuge. After repeated dispersion and centrifugation with hexanaphthene / ethanol mixed solution, obtain about 20nm copper nanoparticles ( figure 2 ). The XRD crystal phase diagram of copper nanoparticles is shown in image 3 shown.

[0030] (2) Use a pipette to take 150 mL of cyclohexane into a round bottom flask with a magnet, add 20 mL of Igepal CO-630 surfactant and 20 mL of the copper nanop...

Embodiment 2

[0033] (1) Weigh 0.8376g of copper acetylacetonate and add it to a 150mL round bottom flask with a magnet. An additional 14.2275 g of oleylamine was added. Under the protection of nitrogen, the temperature was gradually raised to 120°C and kept for 10 minutes to remove impurities such as water in the system. Then, when the temperature was raised to 220° C. at a heating rate of 20° C. / min, 1.4228 g of pentaoctylphosphine was added. Continue heating to 230°C and keep it for 2h, then cool down to room temperature under the protection of nitrogen. After adding 10 mL of ethanol solution, centrifuge. After repeated dispersion and centrifugation with a cyclohexane / ethanol mixed solution, copper nanoparticles with a diameter of about 12 nm were obtained.

[0034] (2) Use a pipette to take 150 mL of cyclohexane into a round bottom flask with a magnet, add 20 mL of Igepal CO-520 surfactant and 40 mL of the copper nanoparticle cyclohexane solution that has been synthesized in the firs...

Embodiment 3

[0037] (1) Weigh 0.8376g of copper acetylacetonate and add it to a 150mL round bottom flask with a magnet. An additional 14.2275 g of oleylamine was added. Under the protection of nitrogen, the temperature was gradually raised to 120°C and kept for 10 minutes to remove impurities such as water in the system. Then, when the temperature was raised to 200° C. at a heating rate of 20° C. / min, 1.4228 g of trioctylphosphine was added. Continue heating to 220°C and keep it for 2h, then cool down to room temperature under the protection of nitrogen. After adding 10 mL of ethanol solution, centrifuge. After repeated dispersion and centrifugation with cyclohexane / ethanol mixed solution, copper nanoparticles of about 20 nm were obtained.

[0038] (2) Use a pipette to take 150 mL of cyclohexane into a round bottom flask with a magnet, add 20 mL of Igepal CO-520 surfactant and 40 mL of the copper nanoparticle cyclohexane solution that has been synthesized in the first step, and stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com