Preparation method for lithium manganese/iron phosphate composite material

A technology of lithium iron manganese phosphate and composite materials, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of difficult industrialization, high cost, and difficult operation, improve conductivity and rate performance, and reduce impedance. and polarization, the effect of shortening the conduction distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of lithium manganese iron phosphate composite material, comprising the following steps:

[0027] Step S110, dissolving the phosphorus-containing compound and the manganese-containing compound in water to form a mixed solution.

[0028] Preferably, the phosphorus-containing compound is selected from at least one of ammonium phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, sodium phosphate, disodium hydrogen phosphate and disodium hydrogen phosphate. More preferably, the phosphorus-containing compound is selected from at least one of ammonium phosphate, diammonium hydrogen phosphate and ammonium dihydrogen phosphate.

[0029] Preferably, the manganese-containing compound is at least one selected from manganese oxalate, manganese chloride, manganese sulfate, manganese nitrate, manganese acetate and manganese formate. More preferably, the manganese-containing compound is at least one selected from manganese oxalate, manganese ni...

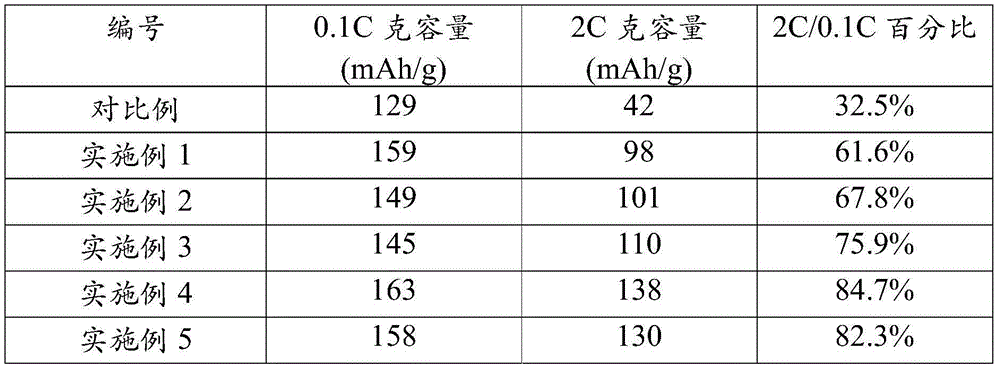

Embodiment 1

[0061] At room temperature (around 25°C), 0.1 mol of (NH 4 ) 2 HPO 4 and 0.1mol of MnCl 2 Dissolve in 800mL of pure water, start to stir, add 150mL of isopropanol dropwise to the solution at a rate of 2mL / S, and a precipitate occurs; continue to stir for 2H, filter the solution to obtain a precipitate, and then wash with pure water for 3 times, at 90 Bake at ℃ for 2H to obtain the precursor MnHPO 4 ·3H 2 O.

[0062] 0.08mol precursor MnHPO 4 ·3H 2 O with 0.05mol Li 2 CO 3 , 0.02mol FeCl 2 and mass for MnHPO 4 ·3H 2 O. Li 2 CO 3 and FeCl 2 3% of the total mass of glucose was mixed, added to the ball mill jar, and 20g of ethanol was added; ball milled for 4H, then the mixture was taken out, baked at 90°C for 3H, and then under the protection of 5% hydrogen-argon gas mixture, the mixture was heated for 3 The rate of ℃ / min is raised to 650 ℃ for 10H and then cooled to obtain carbon-coated lithium iron manganese phosphate LiMn 0.8 Fe 0.2 PO 4 .

Embodiment 2

[0064] At room temperature (around 25°C), 0.2 mol of NH 4 h 2 PO 4 and 0.2mol of Mn(NO 3 ) 4 Dissolve in 2L of pure water, start to stir, drop 300mL of propanol into the solution at a rate of 3mL / S, and a precipitate occurs; continue to stir for 2H, filter the solution to obtain a precipitate, then wash with pure water 3 times, at 90°C Bake for 2H to obtain the precursor MnHPO 4 ·3H 2 O.

[0065] 0.07mol precursor MnHPO 4 ·3H 2 O with 0.105mol LiOH, 0.03mol FeC 2 o 4 and mass for MnHPO 4 ·3H 2 O, LiOH and FeC 2 o 4 5% of the total mass of sucrose was mixed, added to the ball mill jar, and 20g of acetone was added; ball milled for 4H, then the mixture was taken out, baked at 90°C for 3H, and then heated at a rate of 5°C / min under the protection of argon Calcined at 800°C for 8H, cooled to obtain carbon-coated lithium iron manganese phosphate LiMn 0.7 Fe 0.3 PO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com