Insecticidal composition containing etoxazole and amitraz, and preparation and application thereof

An insecticidal composition and the technology of amitraz, applied in the field of pesticides, can solve the problems of acaricide resistance and crop damage, and achieve the effects of improved tolerance, high safety and remarkable synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

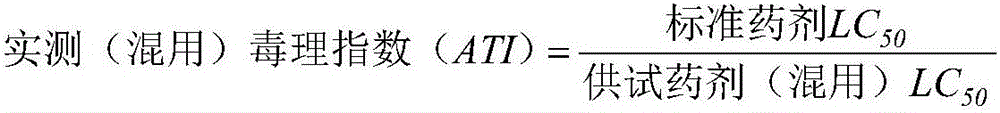

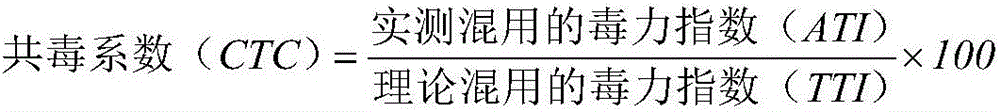

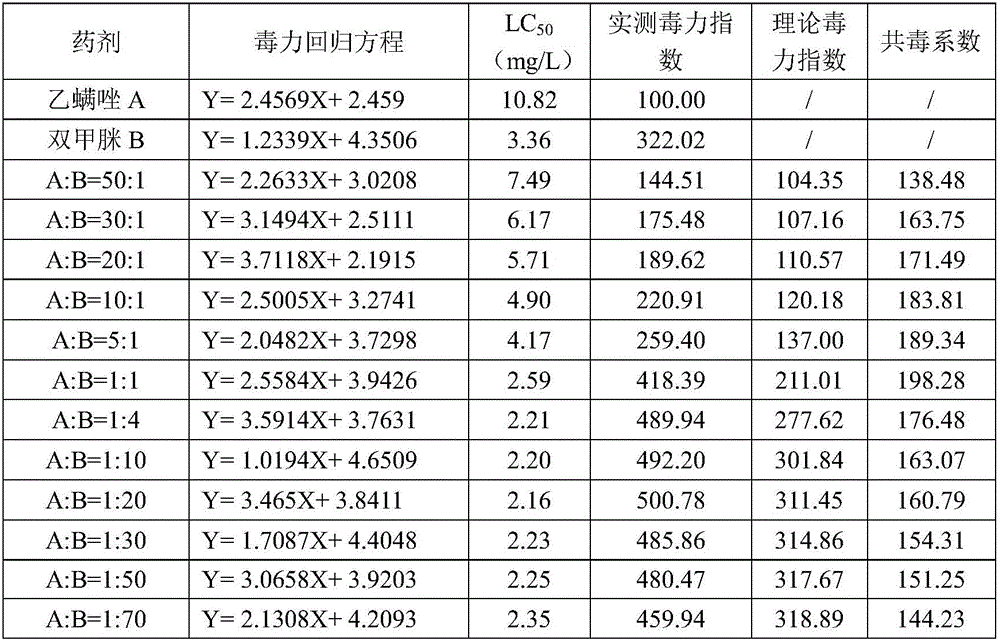

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: 40% (10%+30.0%) suspending agent

[0047] 40% active compound (composition of 10.0% etoxazole and 30.0% amitraz), fatty alcohol polyoxyethylene ether 2.0%, alkylnaphthalene sulfonate 3.0%, sodium methylene dinaphthalene sulfonate 1.0%, Xanthan gum 0.05%, magnesium aluminum silicate 0.6%, glycerol 2.0%, salicylphenyl ester 0.4%, silicone defoamer 0.1%, deionized water to 100%, put into high-shear homogeneous emulsification High-speed shearing in the machine for 20 minutes, then transported to a sand mill, and circularly sanded for 1-3 times to obtain a suspending agent. The suspension contains 40% active compound.

Embodiment 2

[0048] Embodiment 2: 30% (10.0%+20.0%) suspending agent

[0049] 30% active compound (10.0% etoxazole and 20.0% amitraz composition), EO / PO block polyether 1.0%, alkylnaphthalene sulfonate 1.0%, polymer polycarboxylate 4.0%, acrylic acid Homopolymer sodium salt 1.5%, isopropanol 2.0%, organic silicon defoamer 0.1%, sodium benzoate 0.5%, tap water make up to 100%, put it into a high-shear homogeneous emulsifier for 30 minutes at high speed, and then Transport it to a sand mill, and circulate sand for 1-3 times to get 30% suspending agent. The suspension contains 30% active compound.

[0050] 2. Microcapsule suspension

Embodiment 3

[0051] Embodiment 3: 25% (10.0%+15.0%) microcapsule suspension

[0052] 25% active compound (10.0% etoxazole and 15.0% amitraz composition), acyl glutamate 2.0%, phenol sulfonic acid condensate sodium salt 1.0%, silicone defoamer 0.1%, polyphenyl Mix polymethylene polyisocyanate PAPI 3% with diphenylmethane diisocyanate MDI 2%, gum arabic (5%) aqueous solution 10%, and deionized water 39.46%, and then put it into a sand mill for sand grinding. The particle size to D90 is 3-5 microns. Start stirring (maintain 700 rpm), then raise the temperature of the sand-milled suspension to 60°C, and slowly add 0.04% triethanolamine at the same time to maintain a stable solidification temperature of the capsule wall material for 8 hours, then add fatty alcohol polyoxyethylene ether Sulfate 2.0%, alkyl naphthalene sulfonate 1.0%, urea 2.0%, glycerol 2.0%, aluminum magnesium silicate (2%) aqueous solution 10%, appropriate amount of dilute hydrochloric acid aqueous solution to adjust the pH v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com