Organic soil conditioner

An organic soil and conditioner technology, applied in the field of soil pollution control, can solve the problems of excessive harmful components, impact on health status and quality of life, poor taste, etc., and achieve the effect of reducing cadmium content, reducing nutrient loss, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

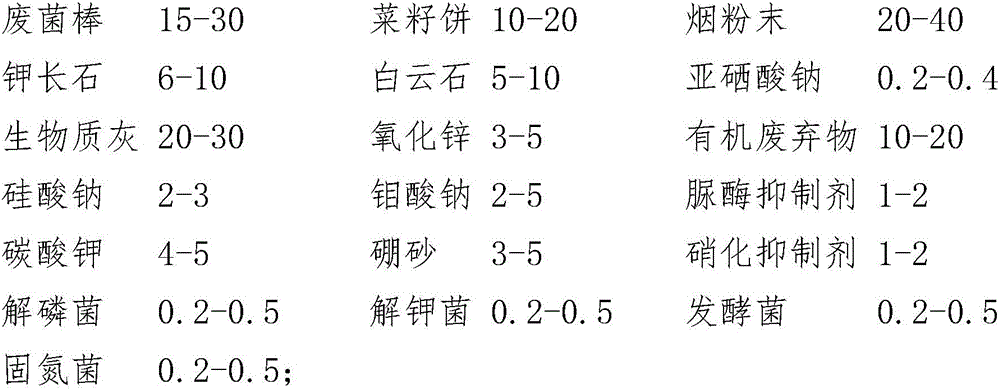

Method used

Image

Examples

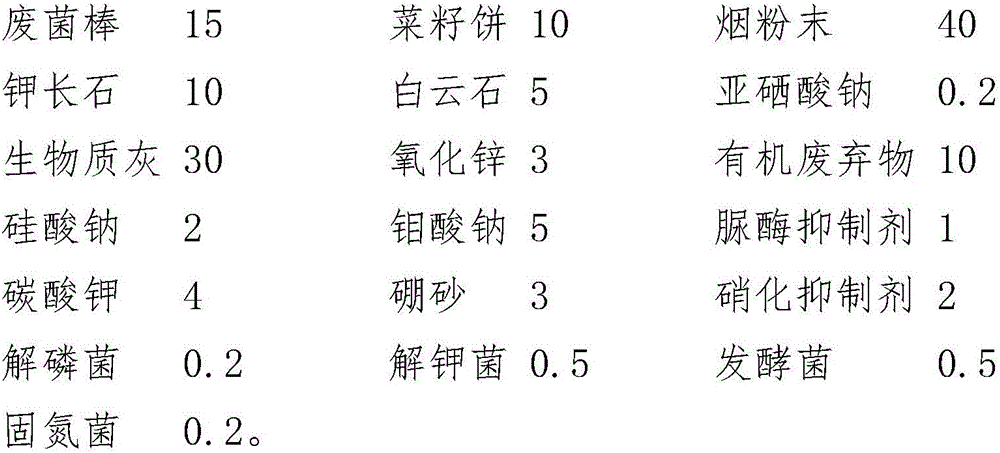

Embodiment 1

[0038] The preparation process of the organic soil conditioner of this embodiment is as follows:

[0039] (1) Material preparation:

[0040] According to parts by weight, take 15 parts of waste fungus sticks, 10 parts of rapeseed cake, 40 parts of smoke powder, 10 parts of potash feldspar, 5 parts of dolomite, 0.2 parts of sodium selenite, 30 parts of biomass ash, and 3 parts of zinc oxide. Parts, organic waste (organic waste, kitchen waste, straw, plant branches and leaves each account for equal parts by weight) 10 parts, sodium silicate 2 parts, sodium molybdate 5 parts, urease inhibitors (p-benzoquinone, hydroquinone, thiourea Each equal parts by weight) 1 part, potassium carbonate 4 parts, borax 3 parts, nitrification inhibitor [2-chloro-6-(trichlorotoluene) pyridine, amidinothiourea (ASU), dicyandiamide (DCD) each Equal parts by weight] 2 parts, 0.2 parts of phosphorus solubilizing bacteria, 0.5 parts of potassium solubilizing bacteria, fermentation bacteria (Bacillus subtili...

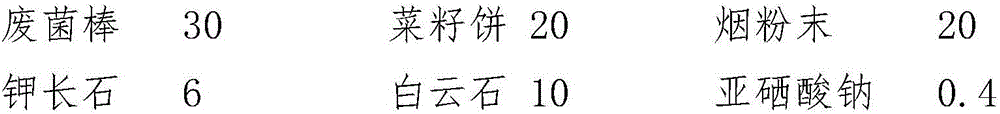

Embodiment 2

[0049] The preparation process of the organic soil conditioner of this embodiment is as follows:

[0050] (1) Material preparation:

[0051] According to parts by weight, take 30 parts of waste fungus sticks, 20 parts of rapeseed cake, 20 parts of smoke powder, 6 parts of potash feldspar, 10 parts of dolomite, 0.4 parts of sodium selenite, 20 parts of biomass ash, and 5 parts of zinc oxide. Parts, organic waste (organic waste, straw, plant branches and leaves each account for equal parts by weight) 20 parts, sodium silicate 3 parts, sodium molybdate 2 parts, urease inhibitor (hexanoyl hydroxamic acid, phenyl mercury acetic acid Salt, copper sulfate each account for equal parts by weight) 2 parts, potassium carbonate 5 parts, borax 5 parts, nitrification inhibitor [amidinothiourea (ASU), dicyandiamide (DCD), 2-sulfathiazole (ST) each account for Equal parts by weight] 1 part, 0.5 part of phosphorus solubilizing bacteria, 0.2 part of potassium solubilizing bacteria, fermentation bac...

Embodiment 3

[0054] The preparation process of the organic soil conditioner of this embodiment is as follows:

[0055] (1) Material preparation:

[0056] According to parts by weight, take 22 parts of waste fungus sticks, 15 parts of rapeseed cake, 30 parts of smoke powder, 8 parts of potash feldspar, 8 parts of dolomite, 0.3 parts of sodium selenite, 25 parts of biomass ash, and 4 parts of zinc oxide. Parts, organic waste (straw, plant branches and leaves each account for equal parts by weight) 15 parts, sodium silicate 2.5 parts, sodium molybdate 4 parts, urease inhibitor (hexanoyl hydroxamic acid, phenyl mercury acetate each accounted for (Equal parts by weight) 1.5 parts, 4.5 parts of potassium carbonate, 4 parts of borax, nitrification inhibitor (amidinothiourea (ASU), dicyandiamide (DCD) each equal parts by weight) 1.5 parts, 0.4 parts of phosphorus solubilizing bacteria, 0.4 parts of potassium bacteria, 0.4 parts of fermenting bacteria (Bacillus subtilis, Bacillus circulans, Bacillus me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com