Method for preparing anionic fluorine-containing polyacrylate soap-free emulsion

A technology of polyacrylate and soap-free emulsion is applied in the field of material preparation to achieve the effect of high utilization rate and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

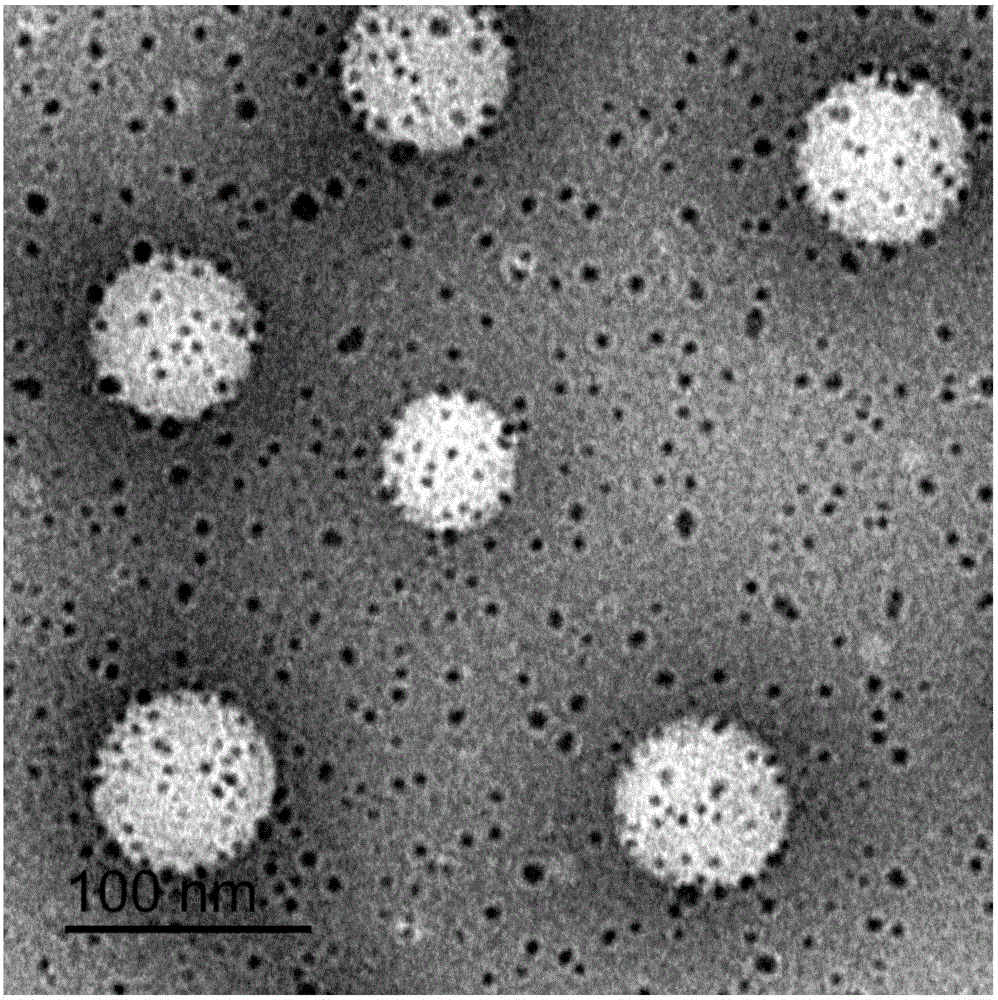

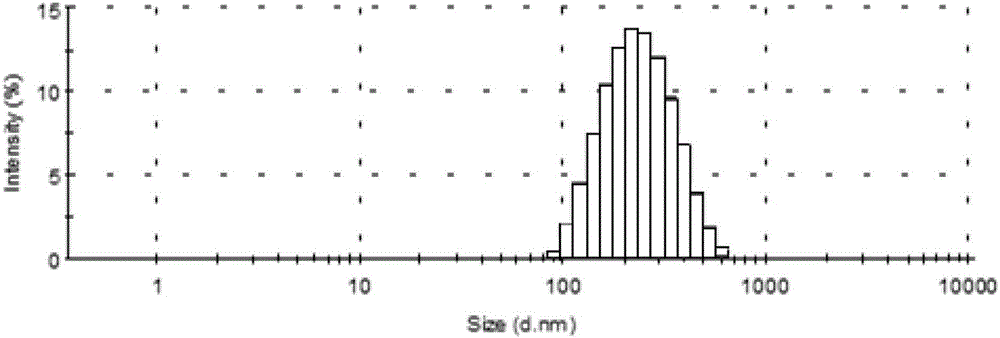

Image

Examples

Embodiment 1

[0085] Weigh methyl acrylate, butyl methacrylate, and hexafluorobutyl methacrylate at a mass ratio of 10:5:1; weigh ammonium persulfate and deionized water at a mass ratio of 1:60; weigh The methyl acrylate, butyl methacrylate and hexafluorobutyl methacrylate were mixed evenly to prepare a mixed monomer; the weighed ammonium persulfate was added to the weighed deionized water, and the over Aqueous solution of ammonium sulfate;

[0086] First weigh the mixed monomer, and then weigh the ammonium sulfate aqueous solution, sodium bicarbonate, deionized water and the brush-type fluorine-containing amphiphilic block copolymer polymer with active end groups of thiocarbonate according to the mass of the mixed monomer. (acrylic acid-co-polyethylene glycol monomethyl ether acrylate)-b-hexafluorobutyl polyacrylate; the quality of ammonium persulfate aqueous solution is 1.4% of the mixed monomer quality; the quality of sodium bicarbonate is the mixed monomer quality 6.7% of 6.7%; the qua...

Embodiment 2

[0093] Weigh methyl acrylate, butyl acrylate and hexafluorobutyl acrylate at a mass ratio of 6:10:1; weigh potassium persulfate and deionized water at a mass ratio of 1:50; weigh the methyl acrylate ester, butyl acrylate and hexafluorobutyl acrylate were mixed evenly to prepare a mixed monomer; the weighed potassium persulfate was added to the weighed deionized water, and after mixing evenly, an aqueous solution of potassium persulfate was prepared;

[0094] First weigh the mixed monomer, and then weigh the potassium persulfate aqueous solution, sodium hydroxide, deionized water and the brush-type fluorine-containing amphiphilic block copolymer with active end groups of thiocarbonate according to the mass of the mixed monomer. Poly(acrylic acid-co-polyethylene glycol monomethyl ether acrylate)-b-polyhexafluorobutyl acrylate; the quality of potassium persulfate aqueous solution is 1.1% of the mixed monomer quality; the quality of sodium hydroxide is the mixed monomer 5.5% of th...

Embodiment 3

[0101] Weigh methyl methacrylate, butyl methacrylate and hexafluorobutyl methacrylate at a mass ratio of 2:5:1; weigh ammonium persulfate and deionized water at a mass ratio of 1:40; Mix the weighed methyl methacrylate, butyl methacrylate and hexafluorobutyl methacrylate to prepare a mixed monomer; add the weighed sodium persulfate to the weighed deionized water, and mix well After preparing sodium persulfate aqueous solution;

[0102]First weigh the mixed monomer, then weigh sodium persulfate, ammonia water, deionized water and brush-type fluorine-containing amphiphilic block copolymer poly(acrylic acid) with active end groups of thiocarbonate according to the mass of the mixed monomer. -co-polyethylene glycol monomethyl ether acrylate)-b-hexafluorobutyl polyacrylate; the quality of sodium persulfate aqueous solution is 0.4% of the mixed monomer quality; the quality of ammonia water is 1.1% of the mixed monomer quality; The quality of deionized water is 300% of the mixed mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com