Injectable bone repair hydrogel and preparation method thereof

A hydrogel and bone repair technology, applied in the field of medicine, can solve the problems of easy disintegration in contact with body fluids, temperature rising to 90°C, long curing time, etc., to promote growth and repair, mild reaction conditions, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

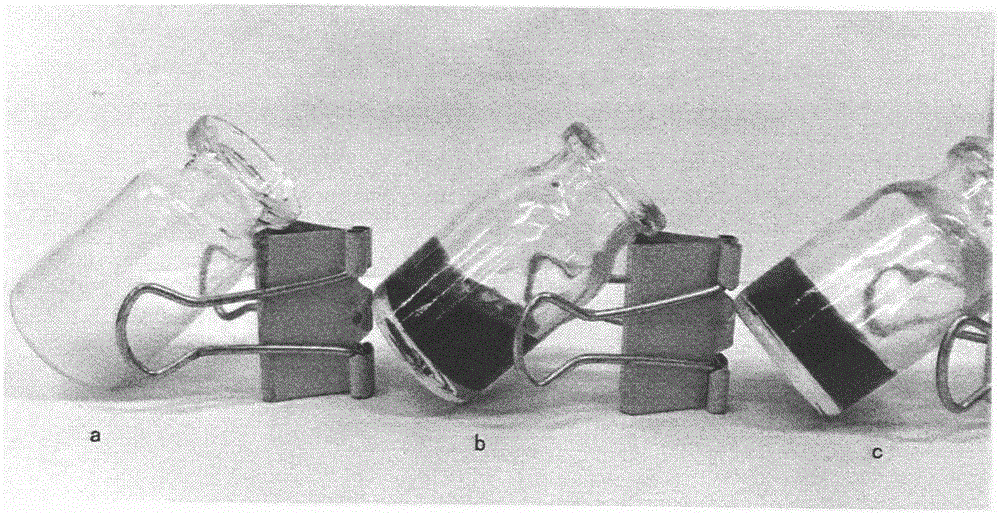

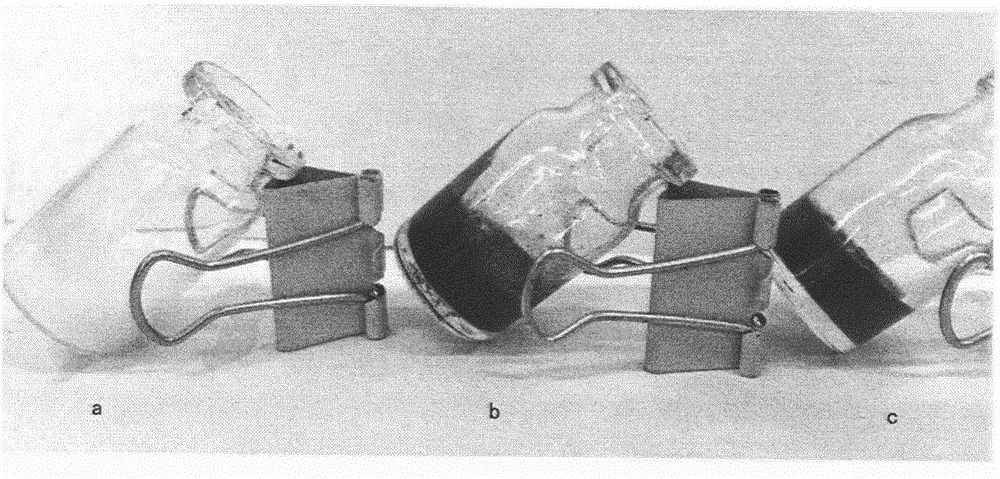

[0024] A preparation method of injectable bone repair hydrogel, the specific steps are as follows:

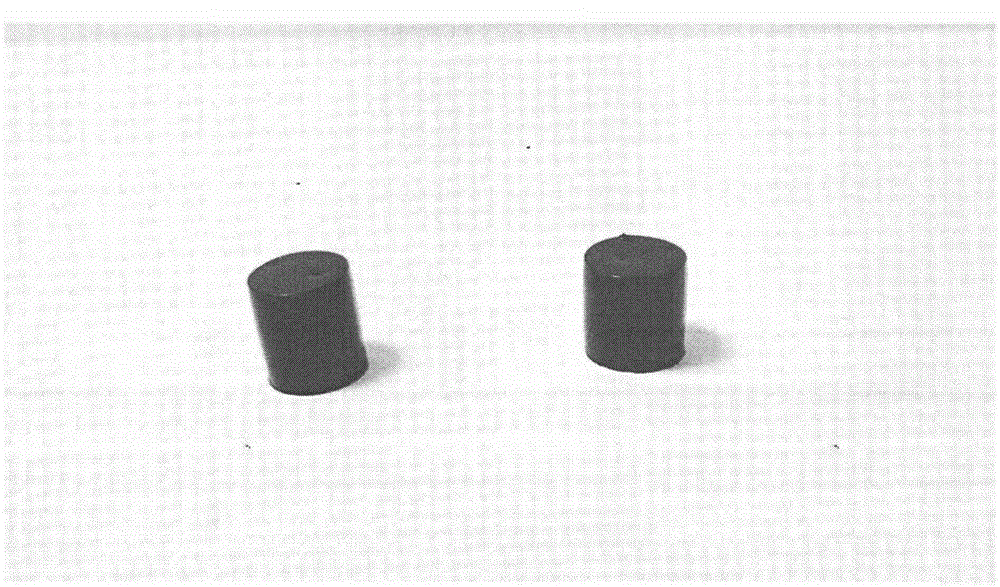

[0025] A. Polydopamine (PDA) modified calcium phosphorus particles

[0026] Disperse calcium-phosphorus particles in 0.5-5 mg / ml dopamine (DA) Tris-HCl solution to form a 0.25%-1% W / V solution, stir for 6-24 hours and then centrifuge to obtain PDA-modified calcium-phosphorus particles (PCP);

[0027] B. Fixed PCP

[0028] Add PDA-modified calcium phosphorus particles (PCP) to 5-20 wt% of degradable natural macromolecular phosphate buffer solution (PBS) with aldehyde groups, and fully mix, wherein the concentration of PCP is 5-20 wt%, to obtain solid A degradable natural polymer phosphate buffer solution with aldehyde groups loaded with PDA-modified calcium-phosphorus particles;

[0029] C. Preparation of hydrogel

[0030] Dissolve the degradable natural polymer with amino groups in phosphate buffer solution (PBS) to form a 2-20 wt% solution, and then mix it with the above-m...

Embodiment 1

[0037] A. PDA modified nano-hydroxyapatite

[0038] Disperse 2g of nano-hydroxyapatite (HA) (particle size 150-200nm) in 100ml Tris-HCl solution of dopamine (DA) with a concentration of 5mg / ml, stir for 12h and then centrifuge to obtain PDA-modified nano-hydroxyapatite Apatite (PHA);

[0039] B, preparation of oxidized sodium alginate (ADA)

[0040] Disperse 5.0g of sodium alginate in 25ml of ethanol to form suspension I, dissolve 3.25g of sodium periodate in 25ml of distillation to form solution II, then add solution II to suspension I, keep stirring for 6 hours before adding 2.5ml of ethylene glycol was used to stop the reaction for 2h, and the reaction mixture was added to 200ml of absolute ethanol which was stirred vigorously. After suction filtration, the product was fully dissolved in distilled water and put into a dialysis bag for dialysis for 3 days; finally, the white product was put into a watch glass and freeze-dried for 3 days to obtain oxidized sodium alginate; ...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is:

[0048] C. Fixation of PHA

[0049] Add PHA to 20wt% ADA phosphate buffer solution (PBS), fully mix, wherein the concentration of PHA is 20wt%, obtain ADA-PHA solution;

[0050] The gel time of the hydrogel was determined to be about 5 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com