Environmentally friendly biomass soil remediation agent and preparation method thereof

A soil remediation agent and biomass technology, applied in the field of soil remediation, can solve problems such as large difference in improvement effect, and achieve the effects of reliable soil remediation performance, good application prospect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

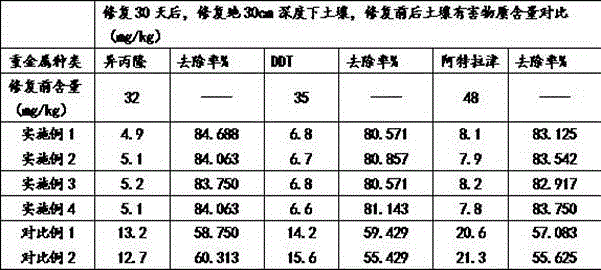

Examples

Embodiment 1

[0022] (1) Weigh 10 parts of black humic acid, 10 parts of dried chicken manure, 5 parts of weathered coal, 3 parts of bagasse, 4 parts of corn straw, 3 parts of rapeseed residue, 2 parts of Jerusalem artichoke extract, and methyl phenol 5 parts, 3 parts of calcium hydroxyphosphate, 5 parts of trisodium phosphate, 3 parts of potassium nitrate, 2 parts of magnesium sulfate, 2 parts of calcium chloride, 2 parts of sodium borate, 7 parts of chitosan, 1 part of manganese dioxide, pentoxide 1 part of vanadium, 1 part of phosphorus bacteria, 2 parts of Bacillus lateralis, 1 part of Streptomyces thermophilic amylase, 2 parts of Streptococcus thermophilic salivarius, 2 parts of butylated hydroxyanisole, 3 parts of sodium salicylate;

[0023] (2) Add black humic acid, dried chicken manure, weathered coal, bagasse, corn stalks, rapeseed residue, Jerusalem artichoke extract, and trisodium phosphate into the spray dryer, and dry to obtain powder. is 240°C, and the outlet air temperature i...

Embodiment 2

[0031] (1) Weigh 12 parts of black humic acid, 12 parts of dried chicken manure, 6 parts of weathered coal, 4 parts of bagasse, 5 parts of corn straw, 5 parts of rapeseed dregs, 4 parts of Jerusalem artichoke extract, and methyl phenol 6 parts, 4 parts of calcium hydroxyphosphate, 7 parts of trisodium phosphate, 5 parts of potassium nitrate, 3 parts of magnesium sulfate, 4 parts of calcium chloride, 3 parts of sodium borate, 8 parts of chitosan, 2 parts of manganese dioxide, pentoxide 1 part of divanadium, 2 parts of Bacillus lateral spores, 1 part of Streptomyces thermomylase, 1 part of Streptococcus salivarius, 2 parts of Bacillus stearothermophilus, 2,6-di-tert-butyl-4-methyl 3 parts of phenolic formaldehyde, 4 parts of magnesium stearate;

[0032] (2) Add black humic acid, dried chicken manure, weathered coal, bagasse, corn stalks, rapeseed residue, Jerusalem artichoke extract, and trisodium phosphate into the spray dryer, and dry to obtain powder. is 240°C, and the outle...

Embodiment 3

[0040] (1) Weigh 14 parts of black humic acid, 13 parts of dried chicken manure, 8 parts of weathered coal, 7 parts of bagasse, 7 parts of corn straw, 8 parts of rapeseed residue, 6 parts of Jerusalem artichoke extract, and 8 parts of methyl phenol 6 parts of calcium hydroxyphosphate, 10 parts of trisodium phosphate, 6 parts of potassium nitrate, 5 parts of magnesium sulfate, 5 parts of calcium chloride, 4 parts of sodium borate, 9 parts of chitosan, 2 parts of manganese dioxide, 2 parts of vanadium, 3 parts of Streptococcus salivarius, 2 parts of Bacillus stearothermophilus, 3 parts of Bacillus colloidus, 5 parts of tert-butyl hydroquinone, 7 parts of 2-ethyl lead acetate;

[0041] (2) Add black humic acid, dried chicken manure, weathered coal, bagasse, corn stalks, rapeseed residue, Jerusalem artichoke extract, and trisodium phosphate into the spray dryer, and dry to obtain powder. is 240°C, and the outlet air temperature is 150°C;

[0042](3) Add methylphenol, calcium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com