Preparation method of meropenem intermediate 4-BMA

A technology of meropenem and 4-BMA, applied in the field of preparation of meropenem intermediate 4-BMA, can solve the problems of unsatisfactory purity and yield, affecting the quality and cost of meropenem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

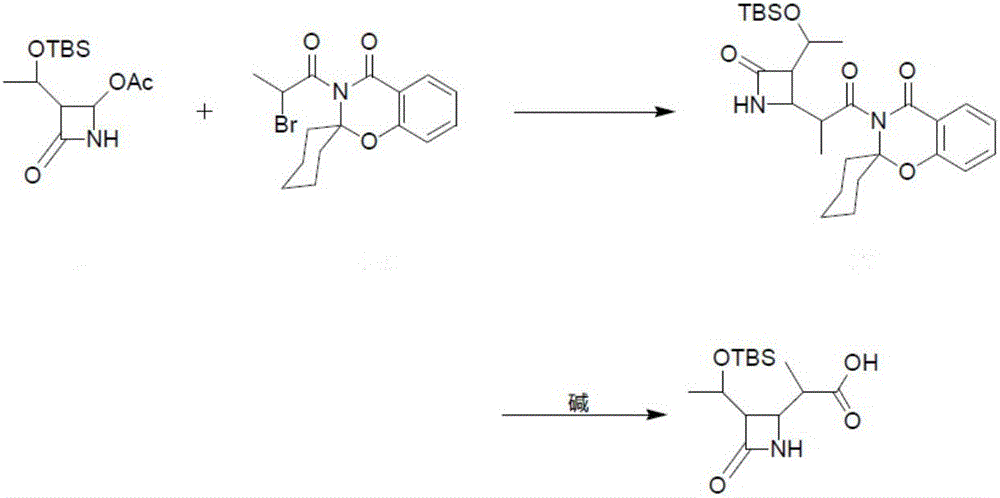

[0023] The present invention provides a preparation method of meropenem intermediate 4-BMA, comprising the following steps:

[0024] A) mixing 4-acetoxyazetidinone, an aprotic solvent and an activated metal to carry out a first reaction;

[0025] B) mixing the product of the first reaction with chloropropionyl spirobenzoxazine cyclohexane to carry out the second reaction;

[0026] C) hydrolyzing the product of the second reaction under hydrogen peroxide and alkaline conditions to obtain 4-BMA.

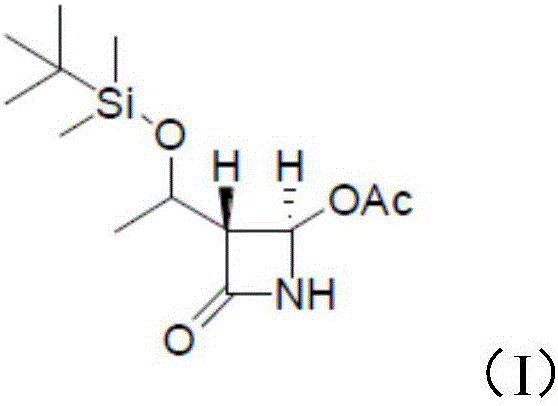

[0027] The 4-acetoxyazetidinone has a structure as shown in formula (I):

[0028]

[0029] The aprotic solvent is preferably one or more of tetrahydrofuran, ethyl acetate, isopropyl ether, benzene, toluene, xylene, chlorobenzene, N,N-dimethylformamide, and dimethyl sulfoxide.

[0030] The activated metal is preferably one or both of magnesium powder and zinc powder.

[0031] In the present invention, the mass ratio of the 4-acetoxyazetidinone to the aprotic solvent is preferably ...

Embodiment 1

[0080] According to the molar ratio of spiro[2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one, α-chloropropionyl chloride and triethylamine is 1:1.4 : 1.2, respectively weigh 80g of spiro[2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one, 65g of α-chloropropionyl chloride and 45g triethylamine; according to the mass ratio of spiro[2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one to toluene as 1:3.1, weigh 250g toluene; according to the mass ratio of [2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one to isopropanol is 1:1, weigh 80g isopropanol.

[0081] Under nitrogen protection, toluene, spiro[2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one, α-chloropropionyl chloride and triethylamine Put it into a four-neck flask for reaction, the reaction temperature is 80°C, and the reaction time is 5h. After the reaction, cool down to room temperature, wash three times with 200g water, three times with 200g 8% sodium hydroxide solution, three times with 200g wa...

Embodiment 2

[0083] According to the molar ratio of spiro[2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one, α-chloropropionyl chloride and pyridine is 1:1.6:1.4 , weigh 80g of spiro[2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one, 75g of α-chloropropionyl chloride and 40g of pyridine ;According to the mass ratio of spiro[2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one to chlorobenzene is 1:4.4, weigh 350g chlorobenzene ; According to the mass ratio of [2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one to ethanol is 1:1, weigh 80g of ethanol.

[0084] Under nitrogen protection, chlorobenzene, spiro[2,3-dihydro-4H-1,3-benzoxazin-2,1'-cyclohexane]-4-one, α-chloropropionyl chloride and pyridine were added The reaction was carried out in a four-neck flask, the temperature of the reaction was 50° C., and the reaction time was 8 h. After the reaction, cool down to room temperature, wash three times with 200g water, three times with 200g 10% potassium hydroxide solution, thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com