Method for extracting myoglobin in pig hearts and human total antioxidant status kit containing myoglobin

A myoglobin and kit technology, applied in the direction of biological testing, preparation of test samples, material inspection products, etc., can solve problems such as inability to meet the mass production requirements of kits, low yield of recombinant myoglobin, and difficulty in obtaining raw materials , to achieve good economic benefits, simple extraction process, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

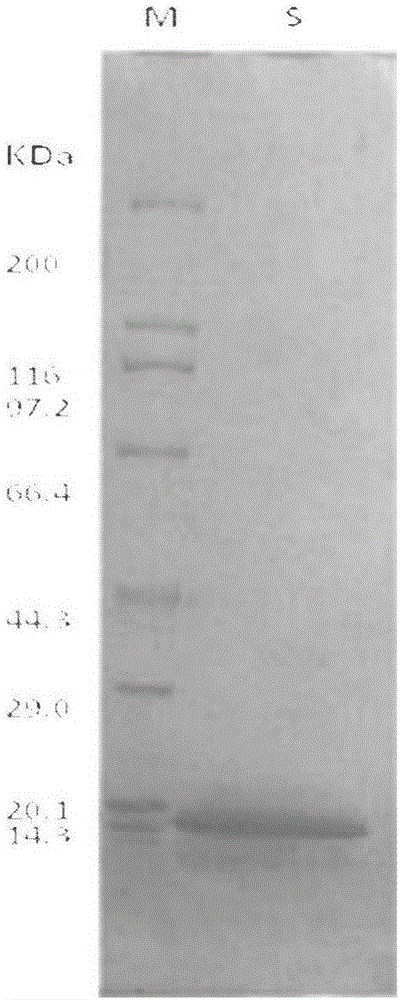

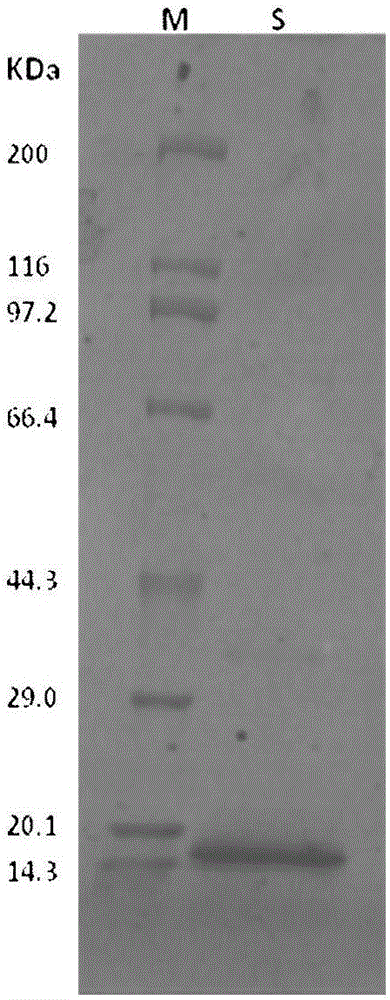

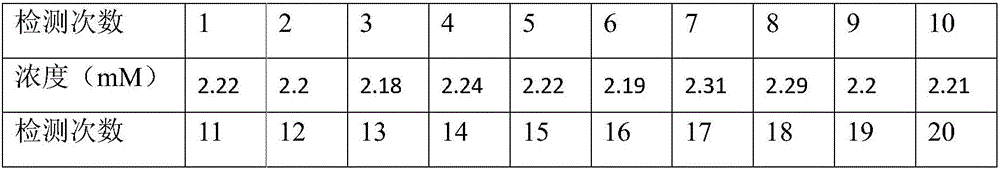

[0044] Example 1: Extraction of myoglobin from pig heart

[0045] 1) After removing the fat and connective tissue of 500g fresh pig heart, add 1000ml 50mM phosphate buffer pH8.0, homogenize quickly with a tissue homogenizer for 5min, centrifuge at 12000rpm for 40min in a high-speed refrigerated centrifuge, remove the precipitate, and obtain the crude extract ;

[0046] 2) Add ammonium sulfate solids accounting for 40% of the mass of the crude liquid to the crude extract, stir gently, and wait for complete dissolution. After precipitation at room temperature for 1 hour, centrifuge with a high-speed refrigerated centrifuge at 12,000 rpm for 40 minutes, discard the precipitate, and keep the supernatant;

[0047] 3) Continue to add solid ammonium sulfate to the supernatant to saturation, stir slightly, wait for complete dissolution, and after precipitation at room temperature for 2 hours, centrifuge with a high-speed refrigerated centrifuge at 12,000 rpm for 40 minutes, discard th...

example 2

[0051] Example 2: Extraction of myoglobin from pig heart

[0052] 1) After removing the fat and connective tissue of 1000g fresh pig heart, add 2000ml 120mM Tris buffer pH8.8, homogenize quickly with a tissue homogenizer for 10min, centrifuge at 12000rpm for 40min in a high-speed refrigerated centrifuge, remove the precipitate, and obtain a crude extract ;

[0053] 2) Add 50% solid ammonium sulfate to the crude extract, stir slightly, wait for complete dissolution, settle at room temperature for 1 hour, centrifuge at 12,000 rpm for 40 minutes in a high-speed refrigerated centrifuge, and keep the supernatant;

[0054] 3) Add ammonium sulfate solid to the supernatant to a saturated state, stir slightly, and wait for complete dissolution. After precipitation at room temperature for 2 hours, centrifuge with a high-speed refrigerated centrifuge at 12,000 rpm for 40 minutes, discard the supernatant, and obtain the precipitate;

[0055] 4) The precipitate was redissolved in 35% ammo...

example 3

[0058] Example 3: Extraction of myoglobin from pig heart

[0059] 1) After removing the fat and connective tissue of 800g fresh pig heart, add 1400ml, 250mM boric acid buffer pH7.2, homogenize rapidly with a tissue homogenizer for 25min, centrifuge at 8000rpm in a high-speed refrigerated centrifuge for 40min, remove the precipitate, and obtain crude extract;

[0060] 2) Add 60% solid ammonium sulfate to the crude extract, stir gently, settle at room temperature for 1 hour, centrifuge at 8000 rpm for 40 minutes in a high-speed refrigerated centrifuge, and keep the supernatant;

[0061] 3) Add ammonium sulfate solid to the supernatant to a saturated state, precipitate at room temperature for 2 hours, centrifuge at 7500 rpm for 50 minutes in a high-speed refrigerated centrifuge, discard the supernatant, and obtain the precipitate;

[0062] 4) The precipitate was redissolved with 40% saturated ammonium sulfate buffer solution to 1400ml, filtered through a 0.8μm filter membrane an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com