High-voltage super-capacitor

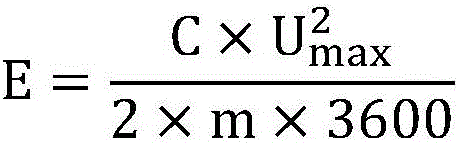

A supercapacitor, high-voltage technology, applied in hybrid capacitor electrodes, protection/regulation hybrid/electric double-layer capacitors, hybrid capacitor electrolytes, etc. The effect of reducing hydrogen bonding, low viscosity, and improving ion mobility can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

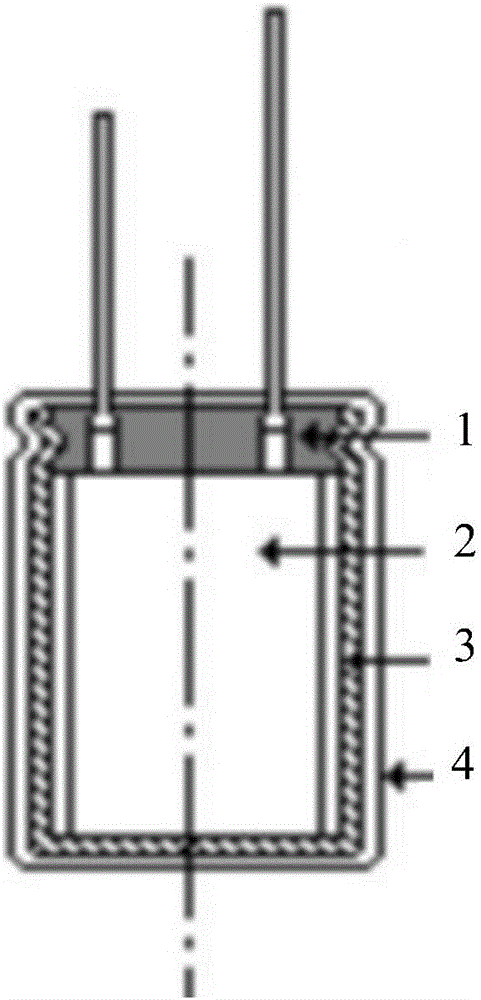

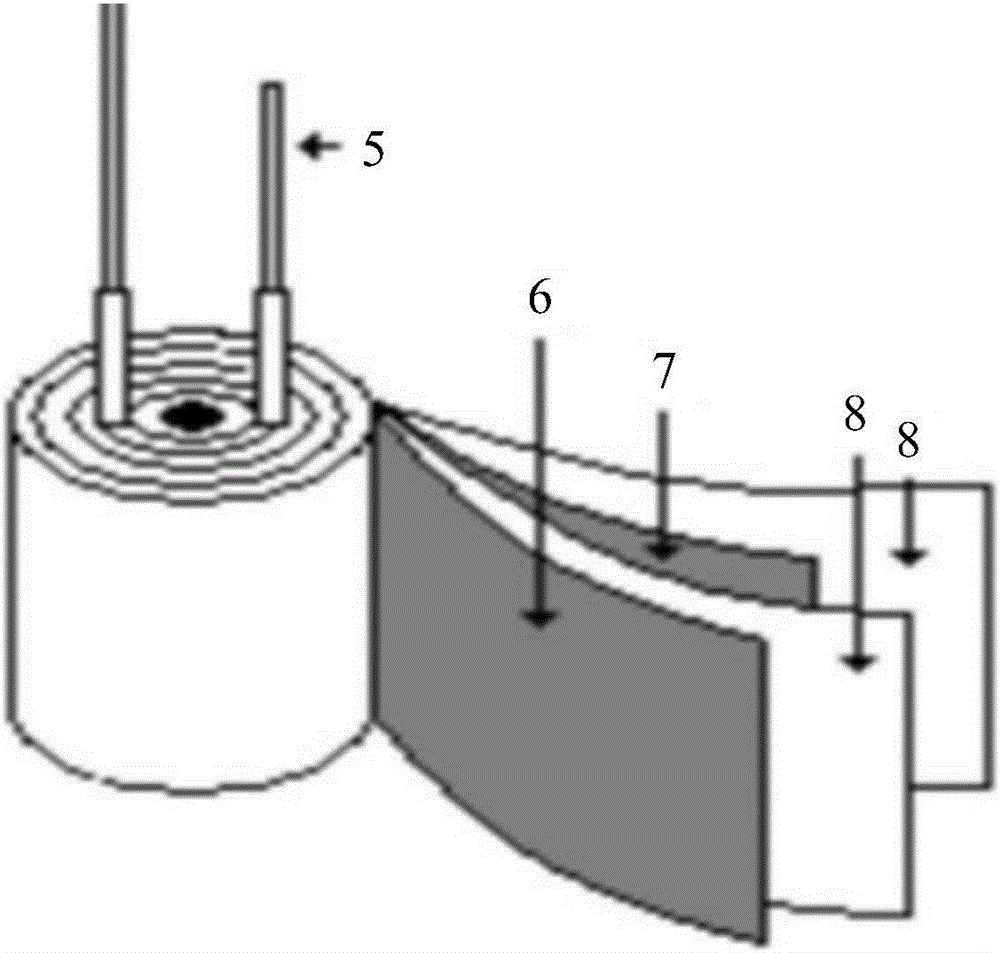

[0077] A 3V supercapacitor

[0078] The preparation method is as follows:

[0079] The electrolyte is a high-voltage resistant electrolyte containing quaternary ammonium salts and high-voltage stabilizers. The electrode is prepared by wet coating. The electrode auxiliary material in the electrode material is a mixture of conductive carbon black, carbon nanotubes and nano-alumina particles.

[0080] (1) Using tetrafluoroborate spirocyclic ammonium salt as electrolyte, acetonitrile as solvent, and tributylamine as high-voltage stabilizer, prepare high-voltage resistant electrolyte, and the tetrafluoroboric acid spirocyclic quaternary ammonium salt in the high-pressure resistant electrolyte The concentration of tributylamine is 1.0mol / L; the mass percentage of tributylamine is 0.5% based on 100% of the total mass of the high-voltage resistant electrolyte.

[0081] (2) In terms of mass percentage, use 5% water-based glue, 85% activated carbon, 8% conductive carbon black, 1% carbo...

Embodiment 2

[0085] A 3V supercapacitor

[0086] The preparation method is as follows:

[0087] The electrolyte is a high-voltage resistant electrolyte containing ionic liquid. The electrode is prepared by wet coating. The electrode auxiliary material in the electrode material is a mixture of conductive carbon black, carbon nanotubes and nano-alumina particles.

[0088] (1) Using 1-ethyl-3-methylimidazolium trifluoromethyl trifluoroborate EMIM-CF 3 BF 3 as the electrolyte, acetonitrile as the solvent, and prepare a high-voltage resistant electrolyte, and the EMIM-CF in the high-voltage resistant electrolyte 3 BF 3 The concentration is 1.0mol / L.

[0089] (2) In terms of mass percentage, use 5% water-based glue, 85% activated carbon, 8% conductive carbon black, 1% carbon nanotubes and 1% nano-alumina particles to make electrode materials (both as positive electrode materials and as negative electrode materials) , the specific method is: fully mix deionized water and water-based glue, ad...

Embodiment 3

[0093] A 3V supercapacitor

[0094] The preparation method is as follows:

[0095] The electrolyte is a high-voltage resistant electrolyte containing ionic liquid and high-voltage stabilizer. The electrode is prepared by wet coating. The electrode auxiliary material in the electrode material is a mixture of conductive carbon black, carbon nanotubes and nano-alumina particles.

[0096] (1) Using 1-ethyl-3-methylimidazolium trifluoromethyl trifluoroborate EMIM-CF 3 BF 3 As electrolyte, acetonitrile as solvent, triethylamine as high-voltage stabilizer, prepare high-voltage resistant electrolyte, and the EMIM-CF in the high-voltage resistant electrolyte 3 BF 3 The concentration of the triethylamine is 1.0mol / L; the mass percentage of triethylamine is 0.5% based on the total mass of the high-voltage electrolyte being 100%.

[0097] (2) In terms of mass percentage, use 5% water-based glue, 85% activated carbon, 8% conductive carbon black, 1% carbon nanotubes and 1% nano-alumina ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com