Ferric oxide@titania nanorod array electrode on titanium substrate and its preparation method

A technology of ferric tetroxide and nanorod arrays, applied in nanotechnology, battery electrodes, nanotechnology and other directions, can solve the problems of inability to significantly improve cycle performance, unsuitable array morphology, poor cycle stability, etc. Effects of transport, suppression of side reactions, and improvement of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

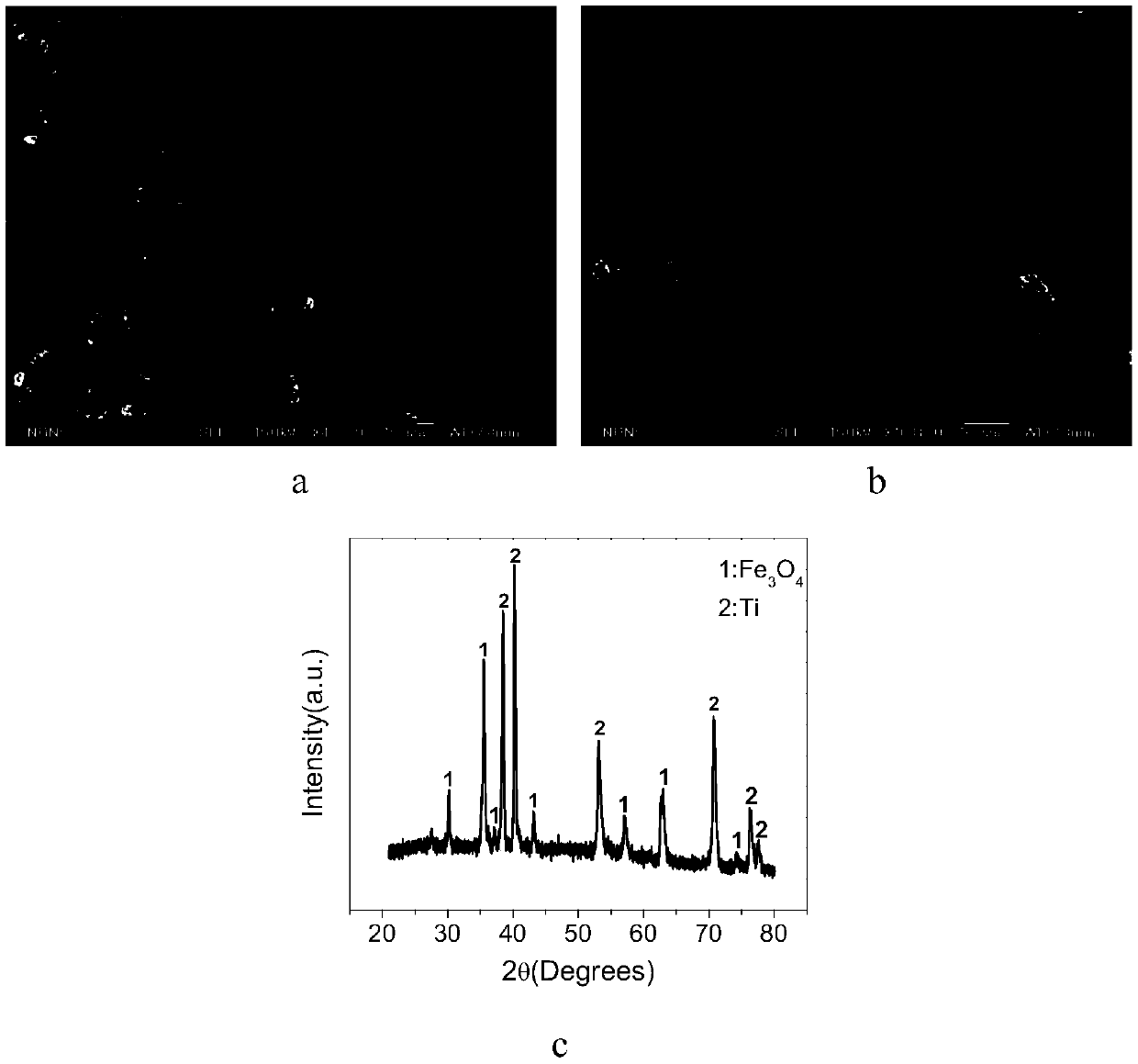

[0032] A ferric oxide nanorod array electrode on a titanium substrate, the preparation method of which comprises: adding 0.946 grams of ferric chloride (FeCl 3 ·6H 2 O) and 0.497 grams of sodium sulfate (Na 2 SO 4 ) was dissolved in 70 milliliters of deionized water, stirred with a magnetic stirrer to make it fully dissolved, and mixed uniformly to obtain a mixed solution; the titanium sheet and the prepared mixed solution were placed together under a high-pressure polytetrafluoroethylene liner substrate and transferred to an oven for hydrothermal reaction at 160°C for 6 hours; after natural cooling, the titanium sheets with nanorod arrays were taken out, washed and dried with deionized water; Heating to 600° C. and annealing for 2 hours, taking out after cooling, and obtaining an array sample of ferric oxide nanorods on a titanium substrate. The sample was observed by scanning electron microscope and X-ray diffraction, the results are shown in figure 1 , figure 1 The res...

Embodiment 2

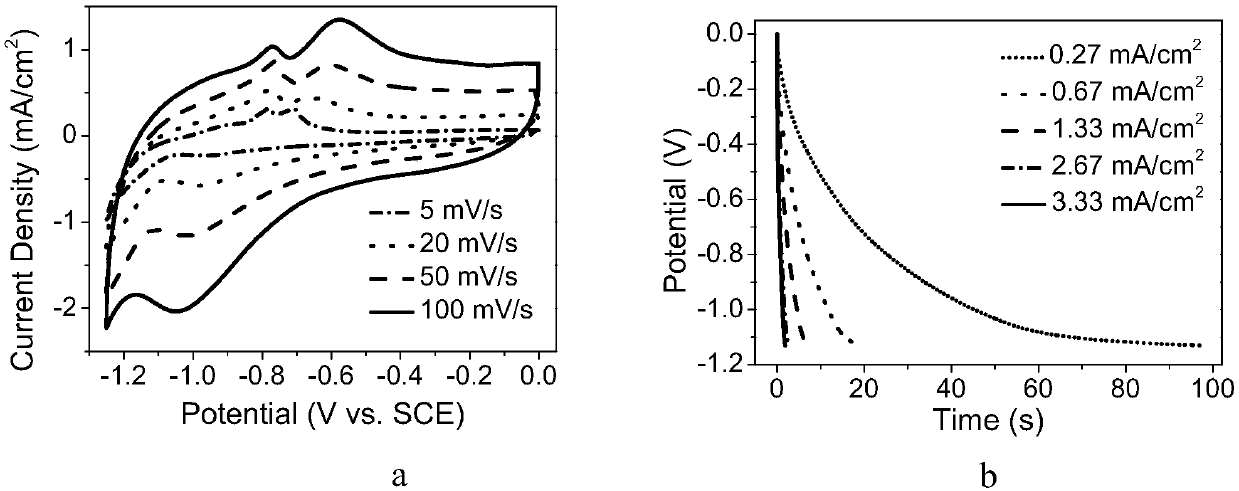

[0035] A composite nanorod array electrode of ferric oxide@titanium dioxide on a titanium substrate, the preparation method of which comprises: using titanium tetrachloride and water as the titanium source and oxygen source respectively for the sample in Example 1, and depositing it by atomic layer deposition technology Titanium oxide: Titanium tetrachloride and water are used as the titanium source and oxygen source respectively. Firstly, the titanium source enters the chamber for 0.2s. After reaching saturated adsorption, the excess titanium source is pumped away and flushed with nitrogen for 20 seconds. Finally, let the oxygen source enter the chamber for 0.2s. After reaching saturated adsorption, the excess oxygen source is pumped away. After flushing with nitrogen for 20 seconds, this is a deposition cycle. According to this, the titanium source and the oxygen source are sequentially pulsed. Alternately feeding into the reactor cavity is a deposition cycle, and the number of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com