Soil conditioner and application thereof in desertification control

A soil improver and desert control technology, applied in the field of soil improver and its application in desert control, can solve the problems of complex formula and preparation process, high cost, unsatisfactory water retention effect, etc., to improve crops and forest fruits Good quality, good water retention, and the effect of improving the water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

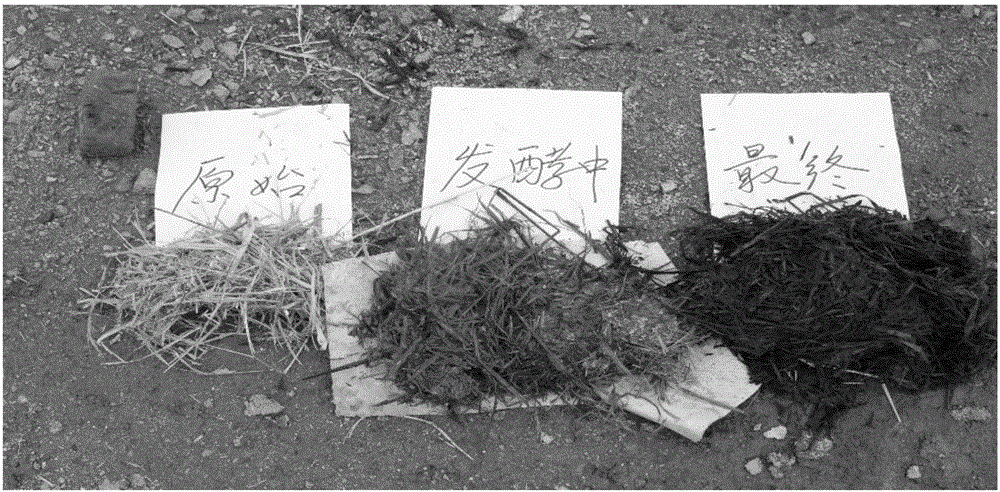

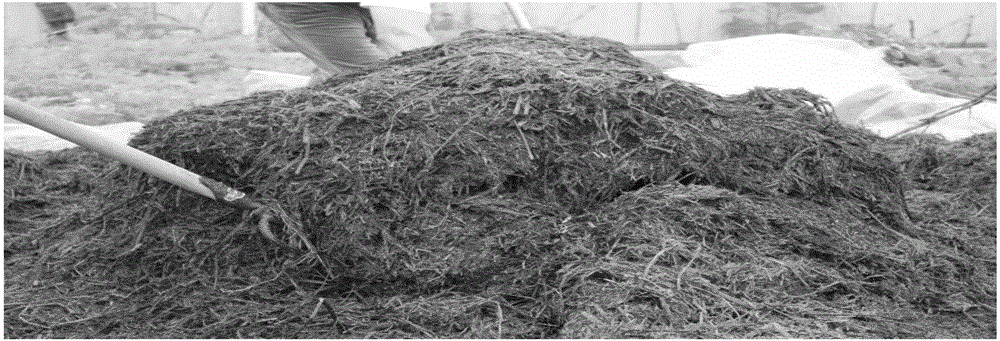

[0051] Embodiment 1: Preparation of decomposed straw

[0052] 1. Main raw materials

[0053] 1. The first microbial agent, by weight:

[0054]

[0055]

[0056] Requirements for the prepared compound bacterial agent: acid protease ≥ 2000u / g, neutral protease ≥ 10000u / g, cellulase ≥ 10000u / g, and the corresponding enzyme preparation is added to the insufficient part.

[0057] Bacillus subtilis KX-1 can survive and reproduce at 2-8°C.

[0058] 2. Volcanic rock biological agents

[0059] Volcanic rock biological preparations are made of porous and large surface area structural properties of volcanic rocks, containing a large amount of silicon, potassium, sodium, iron, magnesium, aluminum, silicon, calcium, titanium, manganese, iron, nickel, cobalt and other dozens of minerals and trace elements, as well as the chelation of heavy metals, using it as a carrier, implanting a variety of beneficial microbial flora that has been verified to be harmless to humans, animals and o...

Embodiment 2

[0120] Example 2: Preparation of biofloc

[0121] Biofloc preparation includes the following steps:

[0122] (1) The decomposed stalks prepared according to the method of Example 1 are pulverized into about 80 meshes with a pulverizer to obtain decomposed stalk powder;

[0123] (2) Add 200 grams of the first microbial bacterial agent per kilogram of decomposed straw powder Add the first microbial bacterial agent to the decomposed straw powder, and then spray nitrifying bacteria and denitrifying bacteria in turn, the addition of nitrifying bacteria and denitrifying bacteria is 100ml Every kilogram of decomposed straw powder can get biofloc.

[0124] For a picture of the resulting biofloc see Figure 5 .

[0125] The organic indicators of the biofloc obtained in this example and the biofloc produced by a foreign company were tested, and the results are shown in Table 4. In addition, the trace elements of the biofloc in this example were tested, and the results are shown in Ta...

Embodiment 3

[0130] Example 3: Soil conditioner

[0131] In the following examples, volcanic ash: produced in Changchun, Jilin; biofloc: prepared by the method and conditions of Example 2 of the present invention (60 mesh); γ-polyglutamic acid: produced by Kunshan Huake, pure biological fermentation; γ-polyglutamic acid Acid water glue: produced by Kunshan Huake Biotechnology, it is absorbed by river water for 60 hours, and the absorption rate is 20 times.

[0132] Example 3-1 This example provides a soil conditioner whose raw materials are composed of volcanic ash, biofloc and γ-PGA hydrogel, the mass ratio of volcanic ash and biofloc is 1:1, and the feeding volume of γ-PGA hydrogel is the same as The mass ratio of volcanic ash is 5L / kg. When in use, mix volcanic ash, biofloc and soil evenly, then add γ-PGA water glue and stir evenly.

[0133] Example 3-2 This example provides a soil conditioner whose raw materials are composed of volcanic ash, biofloc and γ-PGA hydrogel, the mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com