A kind of modified phenolic resin fiber and its preparation method and application

A technology of phenolic resin fiber and phenolic resin, which is applied in the field of modified phenolic resin fiber and its preparation, can solve the problems of poor mechanical properties, poor heat resistance, and low mechanical strength of phenolic fiber, and achieve improved strength and toughness, Effect of improving toughness, good strength and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

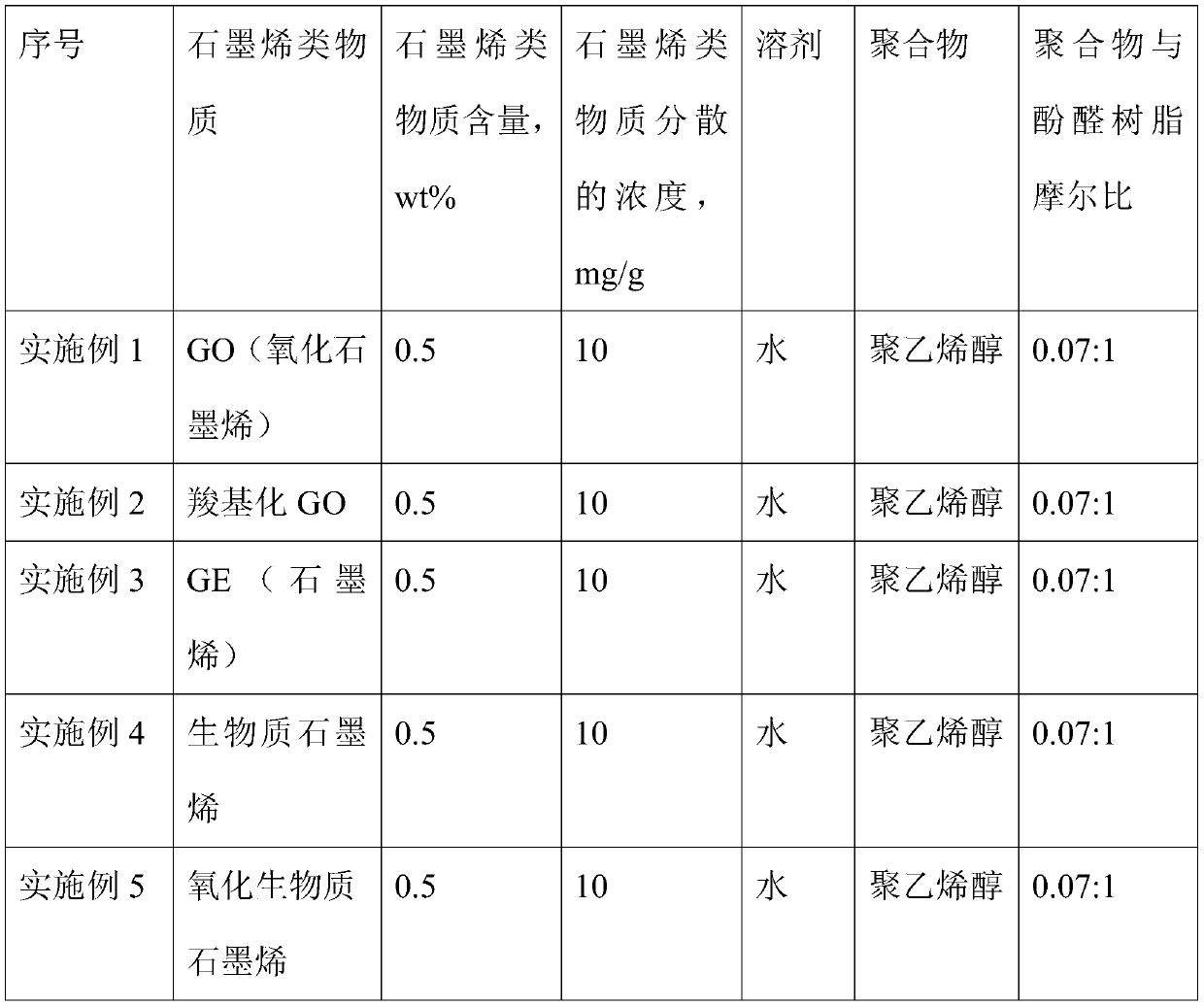

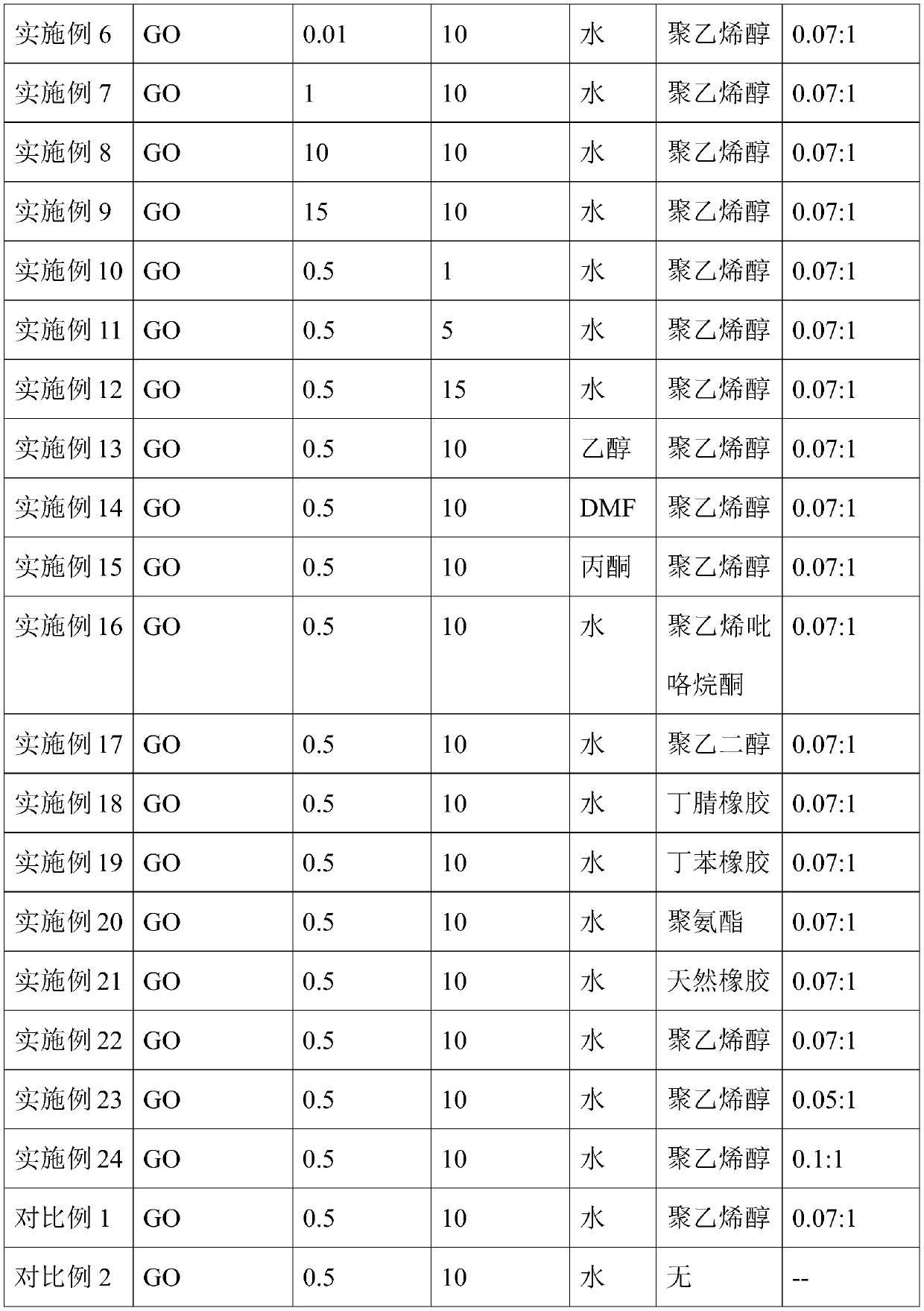

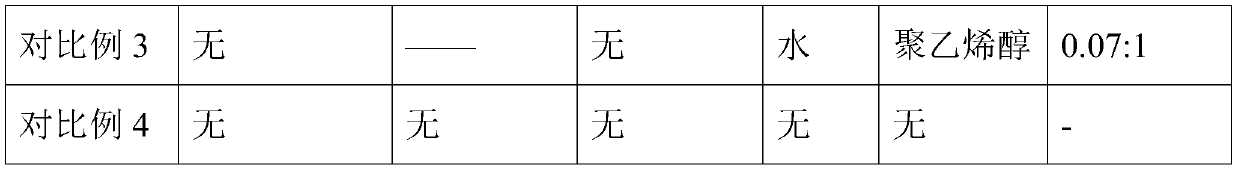

Examples

preparation example 1

[0063] Preparation Example 1: Carboxylated Graphene Oxide

[0064] Ultrasonic disperse 100mg of graphite oxide in 100ml of water to obtain a 1mg / ml graphene oxide aqueous solution, then add 6g of sodium hydroxide and 5g of chloroacetic acid for 3 hours of ultrasonication, so that the epoxy groups and hydroxyl groups on the surface of graphene oxide are converted into carboxyl groups, and the Filter to remove impurities, and then vacuum-dry at 65°C to obtain carboxylated graphene oxide.

preparation example 2

[0065] Preparation example 2: biomass graphene

[0066] Step 1, first prepare cellulose:

[0067] (1) After the wheat straw is pulverized and pretreated, use the organic acid solution whose total acid concentration is 80wt% formic acid and acetic acid to cook the treated wheat straw, the quality of acetic acid and formic acid in the organic acid solution of the present embodiment Ratio is 1:12, and before adding raw materials, add hydrogen peroxide (H2O2) that accounts for 1wt% of wheat straw raw material as catalyst, control reaction temperature 120 ℃, react 30min, solid-liquid mass ratio is 1:10, and will get The reaction liquid is carried out solid-liquid separation for the first time;

[0068] (2) the solid that solid-liquid separation obtains for the first time is added the organic acid liquid that total acid concentration is 75wt% formic acid and acetic acid to carry out acid washing, wherein the organic acid solution that above-mentioned total acid concentration is 75w...

preparation example 3

[0077] Preparation example 3: oxidized biomass graphene

[0078] Due to the porous structure of biomass graphene and the open state of the sheets relative to graphite, the oxidation conditions of biomass graphene are weaker than those of graphite oxidation. The specific implementation process is as follows:

[0079] Mix 2g of biomass graphene with 30mL of concentrated sulfuric acid in the reactor, stir for 10min in an ice-water bath, then gradually add 7g of potassium permanganate, and control the temperature not higher than 35°C. Continue to stir for 2 hours under the conditions, then raise the temperature to 40°C, add about 5mL volume of 30wt% hydrogen peroxide after reacting for 30min, the color of the solution turns golden yellow, then add 150mL distilled water to dilute, suction filter the reaction solution while it is hot, and use 4mL mass fraction of 10% dilute hydrochloric acid and 100mL deionized water are washed 2-3 times, and after centrifugation, the slurry is spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com