A kind of preparation method and application of nickel-promoter-alumina-zirconia catalyst

A catalyst, alumina technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrogenation preparations, etc. Surface area, high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

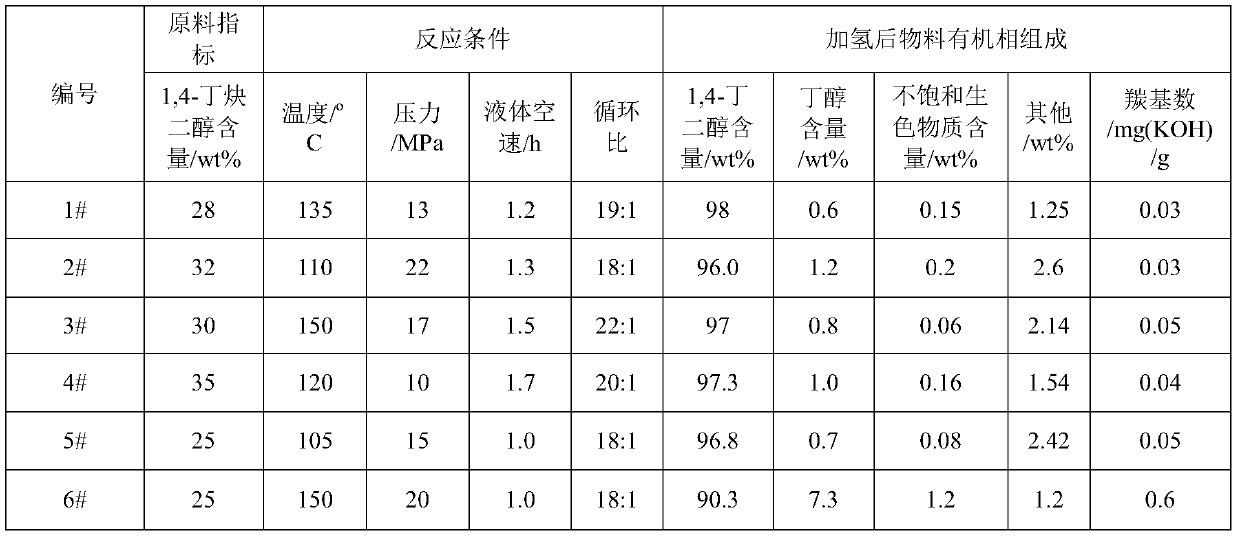

Examples

Embodiment 1

[0028] (1) Weigh 190 g of sodium metaaluminate and add deionized water to prepare 500 mL of an aqueous solution; weigh 4.5 g of polyethylene glycol and 90 g of aluminum chloride, and add deionized water to prepare a 500 mL solution. The above two solutions were co-currently mixed at 50°C to form a gel, and hydrochloric acid was added to adjust the pH of the system to 6. (2) Take 40g of zirconyl nitrate, add deionized water to prepare 500mL aqueous solution, add to the material of step (1) at 50°C under stirring, add sodium carbonate to adjust the pH value to 7, and leave it to stand for 3h. Filter, wash 3 times with water, replace 3 times with ethanol, and dry at 100°C for 12 hours to obtain dry rubber powder containing zirconium. (3) Take 100 g of dry rubber powder, weigh 90 g of nickel nitrate and 3 g of copper nitrate hexahydrate, and mix them evenly with the dry rubber powder. (4) Weigh 0.7 g of formic acid, dilute with 17 g of deionized water to obtain a dilute acid solut...

Embodiment 2

[0031] (1) Weigh 200 g of potassium metaaluminate and add deionized water to prepare a 500 mL solution; weigh 11 g of sucrose and 110 g of aluminum sulfate and add deionized water to prepare a 500 mL solution. The above two solutions were co-currently mixed to form a gel at 75°C, and sulfuric acid was added to adjust the pH of the system to 7. (2) Take 50g of zirconium oxychloride, add deionized water to make 500mL of aqueous solution, add to the material of step (1) at 75°C under stirring conditions, add ammonium carbonate to adjust the pH to 9, and leave it to stand for 5h , Filter, wash 5 times with water, replace 5 times with ethanol, and dry at 150°C for 3 hours to obtain dry rubber powder containing zirconium. (3) Take 100 g of dry rubber powder, weigh 100 g of nickel nitrate and 5 g of copper nitrate, and mix them evenly with the dry rubber powder. (4) Weigh 1.5 g of glacial acetic acid, dilute with 20 g of deionized water to obtain a dilute acid solution, add the dilut...

Embodiment 3

[0034] (1) Weigh 190 g of sodium metaaluminate and add deionized water to prepare a 500 mL solution; weigh 8 g of polyvinylpyrrolidone and 100 g of aluminum nitrate, add deionized water to prepare a 500 mL solution. The above two solutions were co-currently mixed at 60°C to form a gel, and nitric acid was added to adjust the system pH to 7.5. (2) Take 50g of zirconyl nitrate, add deionized water to prepare 500mL aqueous solution, add to the material of step (1) at 60℃, stirring, add sodium hydroxide to adjust the pH value to 8, and leave it to stand for 4h , Filter, wash 3 times with water, replace 4 times with ethanol, and dry at 120°C for 8 hours to obtain dry rubber powder containing zirconium. (3) Take 100g of dry rubber powder, weigh 150g of nickel nitrate and 8g of cerium nitrate, and mix them evenly with the dry rubber powder. (4) Weigh 2.5 g of citric acid, dilute with 22 g of deionized water to obtain a dilute acid solution, add the dilute acid solution to the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com