Main chain degradation type polyacrylic copper resin as well as preparation method and application thereof

A technology of copper polyacrylate, chain degradation, applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve problems such as marine microplastic pollution, achieve thorough polishing, meet antifouling requirements, solve The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

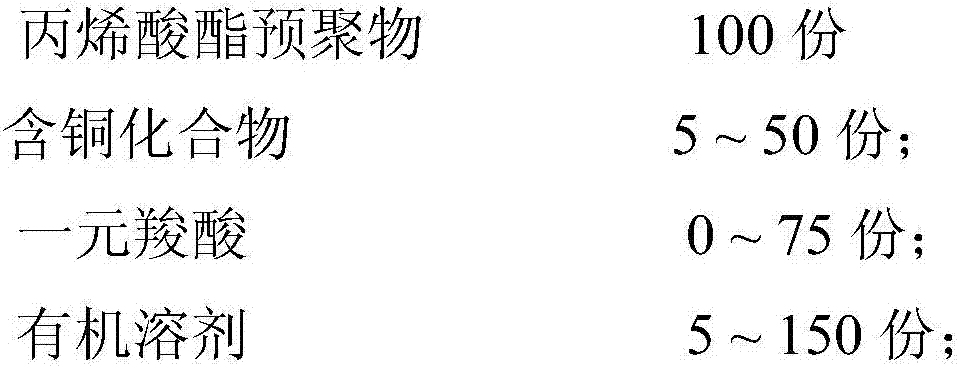

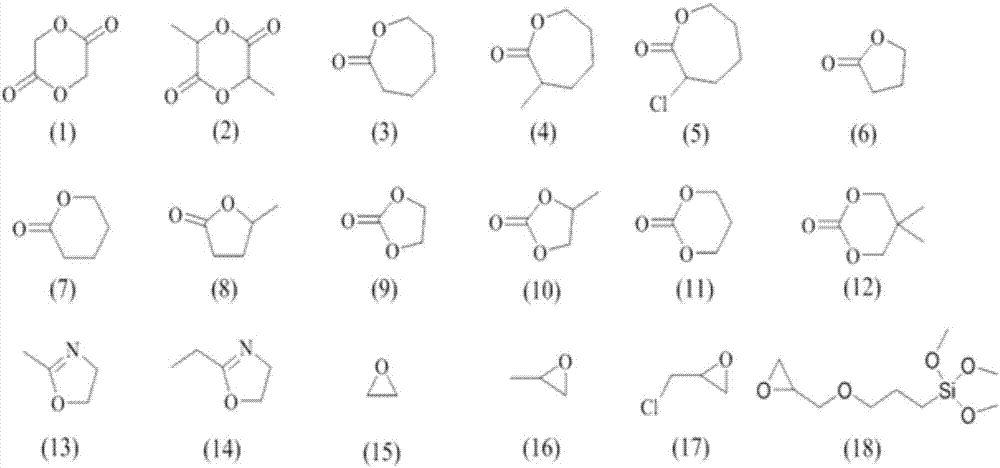

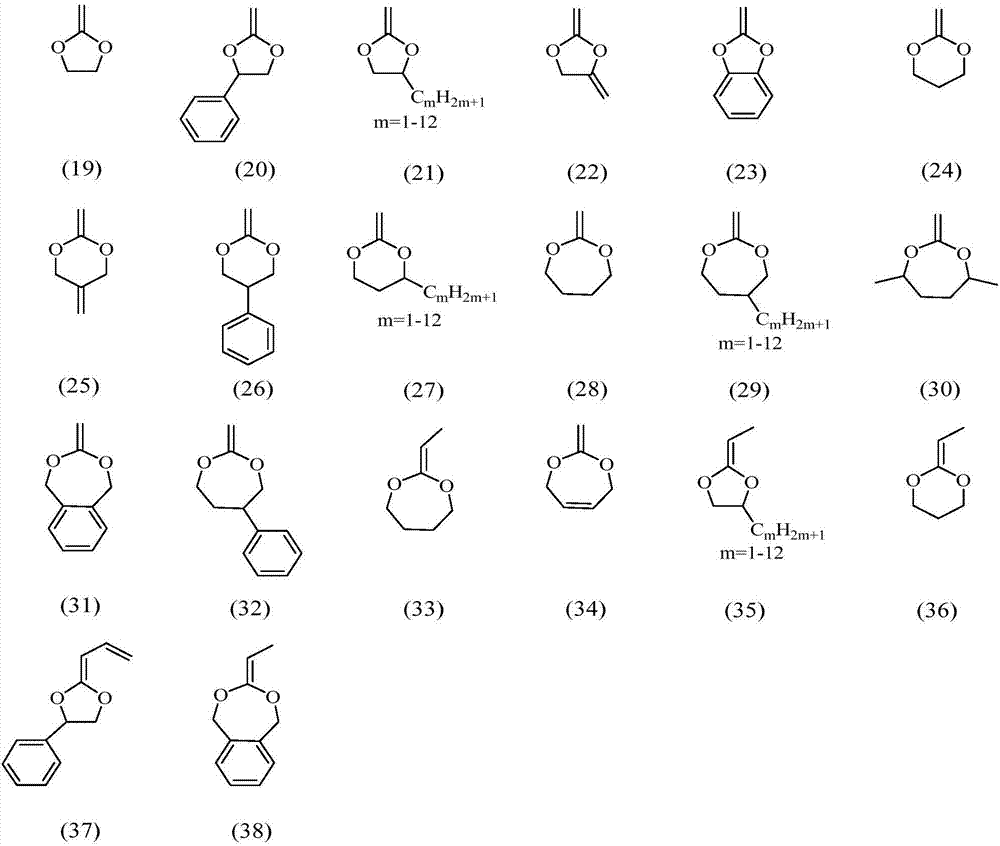

Method used

Image

Examples

Embodiment 1

[0056] (1) In a reaction vessel, add 64 parts by weight of methyl isobutyl ketone and 16 parts by weight of n-butanol, heat to 90°C under a nitrogen atmosphere, drop 25 parts by weight of acrylate stearate, 40 parts by weight of Parts of ethyl methacrylate, 15 parts by weight of 2-methylene-5-phenyl-1,3-dioxetane, 20 parts by weight of acrylic acid, 4 parts by weight of di-tert-butyl peroxide and 2 parts by weight of tetra (3-mercaptopropionic acid) mixture of quaternothritol esters, after the dropwise addition, was incubated for 4 hours to obtain an acrylate prepolymer;

[0057] (2) Add 58.2 parts by weight of copper propionate, 16.7 parts by weight of acetic acid and 100 parts by weight of xylene in the acrylate prepolymer of step (1), and react for 8 hours at 130° C. to obtain copper polyacrylate resin (green transparent resin solution).

[0058] Resin number average molecular weight M in the present embodiment n 1.0×10 4 g / mol, the copper content is 13.2%, and the acid ...

Embodiment 2

[0060] (1) In a reaction vessel, add 64 parts by weight of xylene and 16 parts by weight of propylene glycol methyl ether, heat to 95°C under a nitrogen atmosphere, and dropwise add 20 parts by weight of cyclohexyl methacrylate, 40 parts by weight of methyl Isooctyl acrylate, 10 parts by weight of hydroxyethyl acrylate, 20 parts by weight of 2-ethyl-2-oxazoline, 10 parts by weight of acrylic acid, 0.02 parts by weight of methanol and t-BuP 4 n-hexane solution (containing 0.04 parts by weight of t-BuP 4 ) formed mixture, after the dropwise addition was completed, it was incubated for 4 hours to obtain an acrylate prepolymer;

[0061] (2) Add 11.1 parts by weight of copper oxide, 20.0 parts by weight of isooctanoic acid and 60 parts by weight of xylene in the acrylate prepolymer of step (1), and react for 8 hours at 140° C. to obtain polyacrylic acid copper resin (green transparent resin solution).

[0062] Resin number average molecular weight M in the present embodiment n 1...

Embodiment 3

[0064] (1) In a reaction vessel, add 80 parts by weight of xylene, heat to 100°C under a nitrogen atmosphere, and dropwise add 10 parts by weight of polyethylene glycol methacrylate (polymerization degree is 9), 10 parts by weight of formaldehyde butyl acrylate, 10 parts by weight of 2-methoxyethyl acrylate, 40 parts by weight of acrylate, 20 parts by weight of γ-valerolactone, 10 parts by weight of methacrylic acid, 0.01 parts by weight of diethylene glycol and t-BuP 4 of n-hexane (containing 0.04 parts by weight t-BuP 4 ) formed mixture, after the dropwise addition was completed, it was incubated for 4 hours to obtain an acrylate prepolymer;

[0065] (2) Add 11.33 parts by weight of copper hydroxide, 35.1 parts by weight of abietic acid and 80 parts by weight of xylene in the acrylate prepolymer of step (1), and react for 8 hours at 140° C. to obtain copper polyacrylate resin (green transparent resin).

[0066] Resin number average molecular weight M in the present embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com