Novel hydrothermal template agent of graphene oxide and preparation method of nanocomposite material of novel hydrothermal template agent

A composite material and graphene technology, applied in chemical instruments and methods, carbon compounds, ferrous oxides, etc., can solve the problems of reduced specific surface area, small electromagnetic wave absorption, low magnetic saturation strength of composite materials, etc., to achieve The effect of increasing electronic conductivity, large capacitance, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

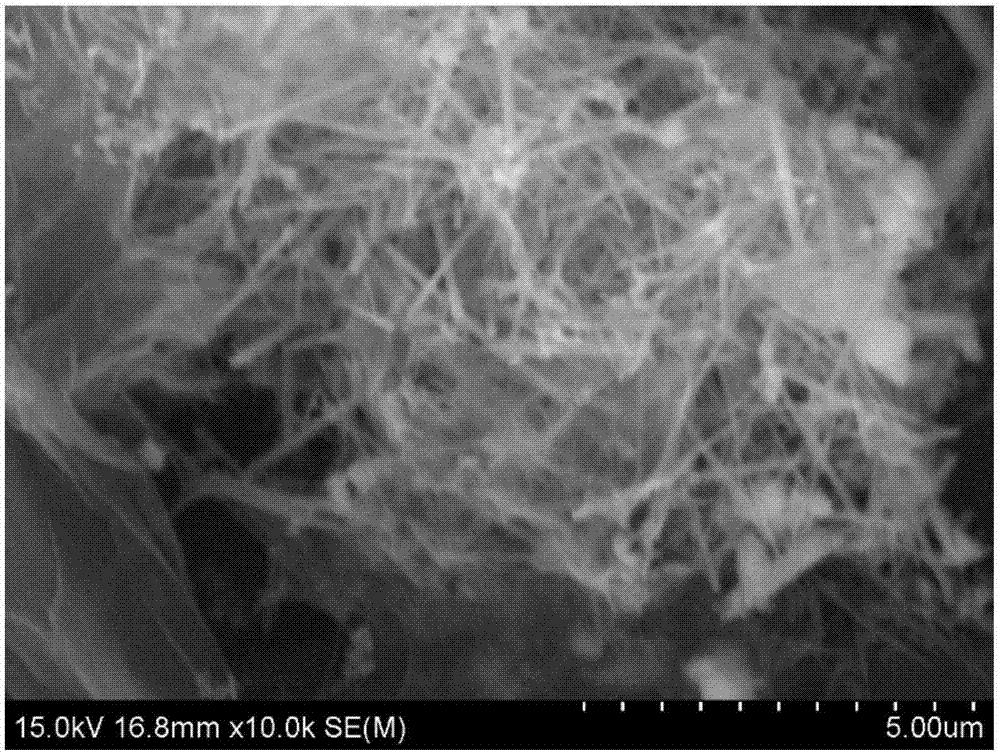

[0070] The preparation process of the reduced graphene oxide / ferric oxide nanowire composite material, the specific steps are as follows:

[0071] Step 1: using the graphene oxide aqueous solution prepared by the improved Hummers method, washing the graphene oxide to pH = 4-6, and then using a vacuum freeze-drying method to prepare graphene oxide powder. At room temperature, 200 mg of graphene oxide was dissolved in 40 ml of water, ultrasonicated for 2 hours, and magnetically stirred for 6 hours to obtain a uniformly dispersed graphene oxide solution A.

[0072] Step 2: Dissolve 8g of sodium hydroxide (NaOH) into solution A, and magnetically stir for 1 hour to obtain solution B in which NaOH is completely dissolved.

[0073] Step 3: take by weighing 1.984g of sodium thiosulfate pentahydrate (Na 2 S 2 o 3 ·5H 2 O) and 4.448g of ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) mixing and pouring into a 50ml Teflon reactor lining, and pouring 40ml solution B into the reactor. ...

Embodiment 2

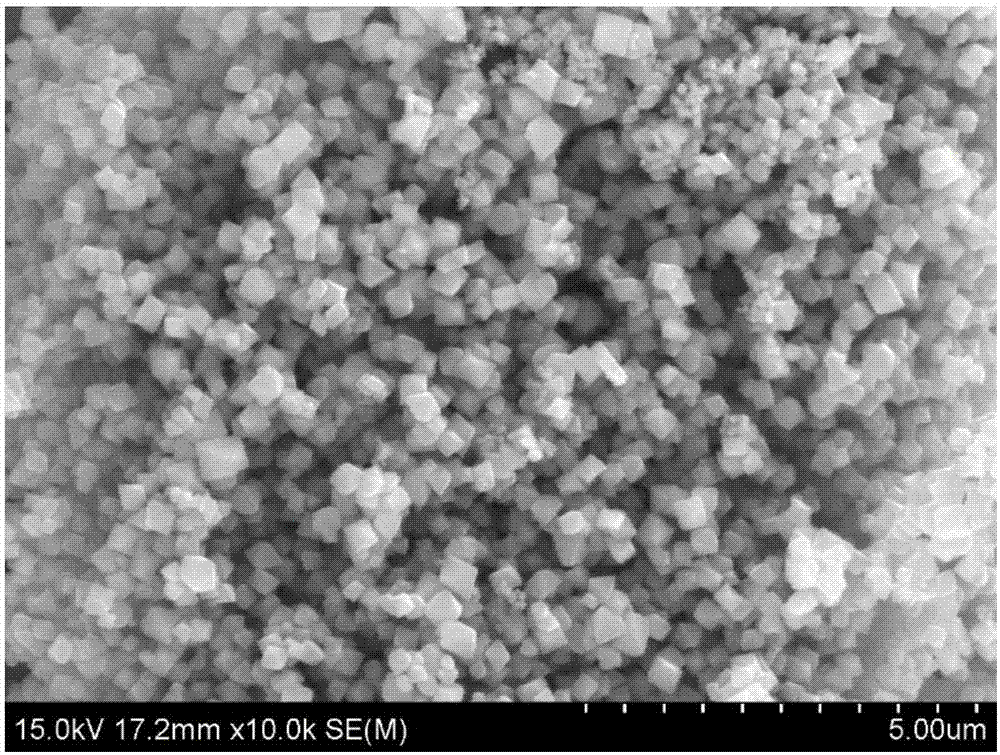

[0078] The preparation process of the reduced graphene oxide / cobalt trioxide nanowire composite material, the specific steps are as follows:

[0079] Step 1: using the graphene oxide aqueous solution prepared by the improved Hummers method, washing the graphene oxide to pH = 4-6, and then using a spray drying method to obtain graphene oxide powder. At room temperature, 200 mg of graphene oxide was dissolved in 40 ml of polyethylene glycol PEG200, PEG400, PEG600 or PEG aqueous solution as a reaction solution, ultrasonicated for 2 hours, and magnetically stirred for 6 hours to obtain a uniformly dispersed graphene oxide solution A.

[0080] Step 2: Dissolve 8g of sodium hydroxide (NaOH) into solution A, and magnetically stir for 1 hour to obtain solution B in which NaOH is completely dissolved.

[0081] Step 3: take by weighing 1.984g of sodium thiosulfate pentahydrate (Na 2 S 2 o 3 ·5H 2 O) and 4.496g of cobalt sulfate heptahydrate (CoSO 4 ·7H 2 O) mixing and pouring into...

Embodiment 3

[0086] The preparation process of the composite electromagnetic shielding coating containing reduced graphene oxide / ferric oxide nanowires, the specific steps are as follows:

[0087] Step 1: Weigh 6g of epoxy resin, put it into a 50ml beaker, add 4g of alcohol, and stir magnetically for 24 hours until the epoxy resin is evenly dispersed to obtain a mixed solution A with a mass fraction of epoxy resin of 60%.

[0088] Step 2: Weigh 6g of epoxy resin curing agent, add it to a 50ml beaker, add 4g of alcohol, and stir magnetically for 24 hours until the curing agent is evenly dispersed to obtain a mixed solution B with a mass fraction of epoxy resin curing agent of 60%.

[0089] Step 3: Weigh 1.3g of the reduced graphene oxide / ferric oxide nanowire composite and add it to the mixed solution A in step 1, stir it evenly with a glass rod, and mix it with the mixed solution B in step 2 to obtain the mass Fraction 10% EMI shielding paint.

[0090] Step 4: Coat the coating in step 3 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com