Preparation method of anti-corrosion lithium battery shell

A lithium battery, corrosion-resistant technology, applied in the field of polymers, can solve the problems of little achievements, insufficient research on inner layer materials, poor strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

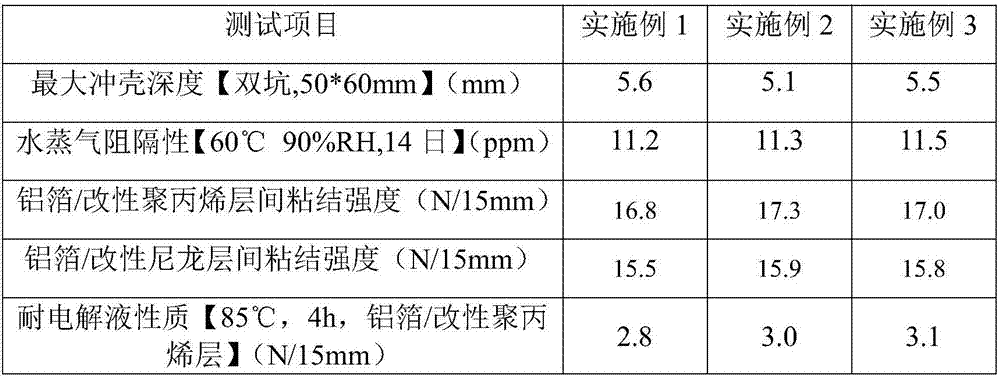

Examples

preparation example Construction

[0019] The invention provides a method for preparing a corrosion-resistant lithium battery case, comprising the following steps: 80-120 parts by mass of polypropylene, 70-100 parts by mass of polyarylether nitrile ketone, 50-100 parts by mass of propylene trimethoxysilane, 15 -30 parts by mass of nano silicon tetranitride and 10-20 parts by mass of silane coupling agent KH792 carry out electron beam irradiation grafting, the irradiation dose is 10-50kGy, stir to obtain mixture A; the mixture A and 10 - 25 parts by mass of astaxanthin are mixed, placed in a twin-screw mixer, extruded and grafted, dried and granulated. The head temperature is 160-200°C, and the screw speed is 180-220r / min to obtain the modified Polypropylene material; the modified polypropylene material and the modified nylon material are sprayed on both sides of the aluminum foil by using a supersonic plasma spraying system, the spraying current is 300-400A, and the spraying distance is 100-200mm to obtain a cor...

Embodiment 1

[0039] 80 mass parts of polypropylene (K8303), 100 mass parts of polyarylether nitrile ketone, 50 mass parts of propylene trimethoxysilane, 30 mass parts of nano silicon tetranitride and 10 mass parts of silane coupling agent KH792 are subjected to electron beam irradiation According to the grafting, the irradiation dose was 50kGy respectively, and the stirring was kept throughout the whole process to obtain the mixture A.

[0040] After the above-mentioned mixture A and 10 parts by mass of astaxanthin were fully mixed and uniform, they were placed in a twin-screw mixer, extruded and grafted, dried and granulated. Among them, the blending and extrusion temperature of the twin-screw kneader is: 180°C for the first zone, 180°C for the second zone, 200°C for the third zone, 200°C for the fourth zone, 220°C for the fifth zone, 160°C for the machine head, and 220r / min for the screw speed. A modified polypropylene material is obtained.

[0041] Then place the aluminum foil in a mix...

Embodiment 2

[0046] 120 mass parts of polypropylene (K8303), 70 mass parts of polyarylether nitrile ketone, 100 mass parts of propylene trimethoxysilane, 15 mass parts of nano silicon tetranitride and 20 mass parts of silane coupling agent KH792 are subjected to electron beam irradiation According to the grafting, the irradiation dose was 10kGy respectively, and the stirring was kept throughout the whole process to obtain the mixture A.

[0047] After the above-mentioned mixture A and 25 parts by mass of astaxanthin were fully mixed and uniform, they were placed in a twin-screw mixer, extruded and grafted, dried and granulated. Among them, the blending and extrusion temperature of the twin-screw kneader is: 170°C for the first zone, 190°C for the second zone, 190°C for the third zone, 210°C for the fourth zone, 210°C for the fifth zone, 200°C for the machine head, and 180r / min for the screw speed. A modified polypropylene material is obtained.

[0048] Then place the aluminum foil in a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com