Inorganic electrochromic charge storage electrode and preparation method thereof

An electrochromic, charge storage layer technology, applied in the direction of ion implantation plating, coatings, instruments, etc., can solve the problems of low transmittance, complex preparation process, low film adhesion, etc., to achieve strong storage capacity, process Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

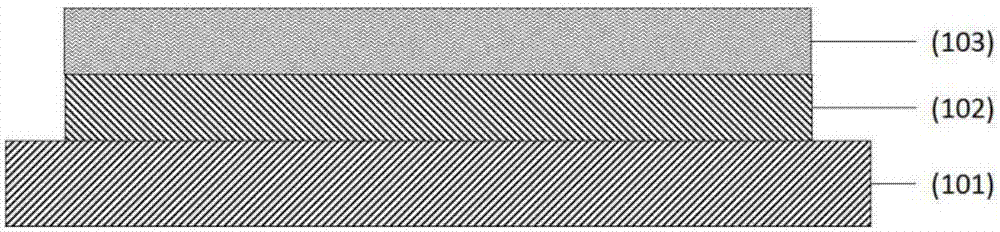

[0034] (1) Use acetone, ethanol and purified water to ultrasonically clean the inorganic glass for 15 minutes. After purging with nitrogen, place it in an oven for drying treatment to remove oil and impurities on the surface, and place the clean and dry glass substrate in the vacuum chamber. Indoor, the deposition method is DC magnetron sputtering deposition, the target material is ITO target, the target base distance is 9cm, and the vacuum pump is used to reduce the chamber vacuum to 1×10 -3 Pa, adjust the argon and oxygen gas flow meters to keep the chamber pressure at 1.0 Pa, where the argon-oxygen ratio is 30 / 1, the substrate temperature is room temperature, the deposition power is 100W, the deposition rate is 50nm / min, and the deposition thickness is 300nm;

[0035] (2) Place the glass substrate with the deposited transparent conductive layer in a vacuum annealing furnace, annealing at 250°C for 30 minutes under a 1Pa argon atmosphere, and cooling to room temperature along wit...

Embodiment 2

[0040] (1) Use acetone, ethanol and purified water to ultrasonically clean the inorganic glass for 15 minutes. After purging with nitrogen, place it in an oven for drying treatment to remove oil and impurities on the surface, and place the clean and dry glass substrate in the vacuum chamber. Indoor, the deposition method is DC magnetron sputtering deposition, the target material is Al-doped ZnO (AZO) target, the target base distance is 9cm, and the vacuum pump is used to reduce the chamber vacuum to 1×10 -3 Pa, adjust the argon and oxygen gas flowmeters to keep the chamber pressure at 0.8Pa, where the argon-oxygen ratio is 25 / 1, the substrate temperature is room temperature, the deposition power is 100W, the deposition rate is 40nm / min, and the deposition thickness is 100nm; Continue to deposit the second transparent conductive layer of ITO with an ITO target, the target base distance is 9cm, and use a vacuum pump to reduce the chamber vacuum to 1×10 -3 Pa, adjust the argon and o...

Embodiment 3

[0046] (1) Use acetone, ethanol and purified water to ultrasonically clean the inorganic glass for 15 minutes. After purging with nitrogen, place it in an oven for drying treatment to remove oil and impurities on the surface, and place the clean and dry glass substrate in the vacuum chamber. Indoor, the deposition method is DC magnetron sputtering deposition, the target material is Al-doped ZnO (AZO) target, the target base distance is 9cm, and the vacuum pump is used to reduce the chamber vacuum to 1×10 -3 Pa, adjust the argon and oxygen gas flowmeters to keep the chamber pressure at 0.8 Pa, where the argon-oxygen ratio is 25 / 1, the substrate temperature is room temperature, the deposition power is 100W, the deposition rate is 40nm / min, and the deposition thickness is 80nm; Use GZO target, target base distance is 9cm, use vacuum pump to reduce chamber vacuum to 1×10 -3 Pa, adjust the argon and oxygen gas flowmeters to keep the chamber pressure at 0.5Pa, where the argon-oxygen ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com