Application of fluoro-substituted phosphate in preparation of lithium ion battery electrode, lithium

A fluorophosphate, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cycle capacity attenuation, high industrialization cost, poor rate performance, etc., and achieve battery rate performance improvement and battery safety. The effect of improving performance and improving the condition of lithium precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

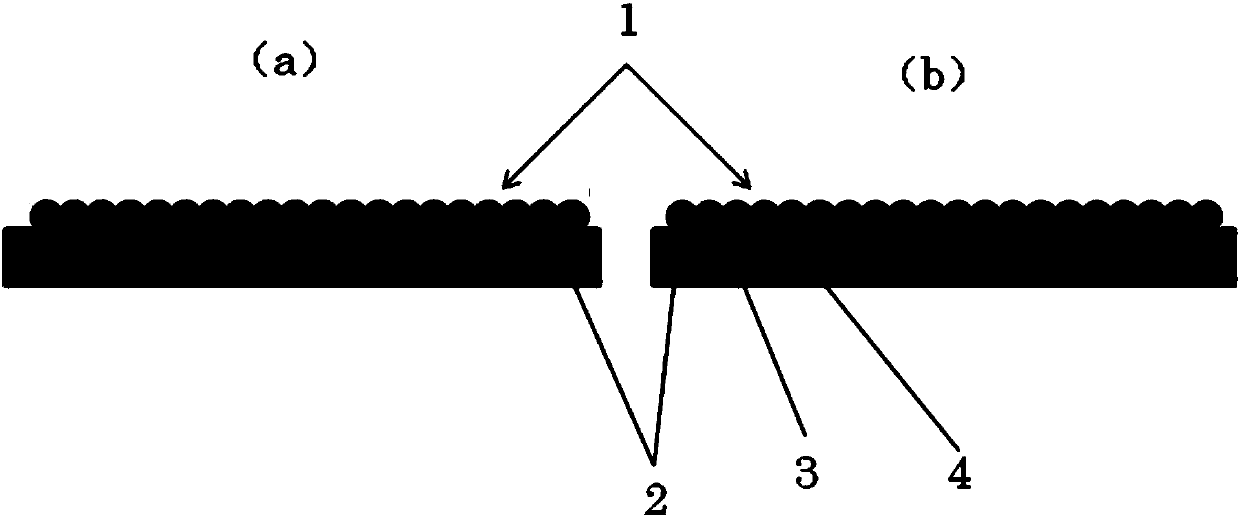

Image

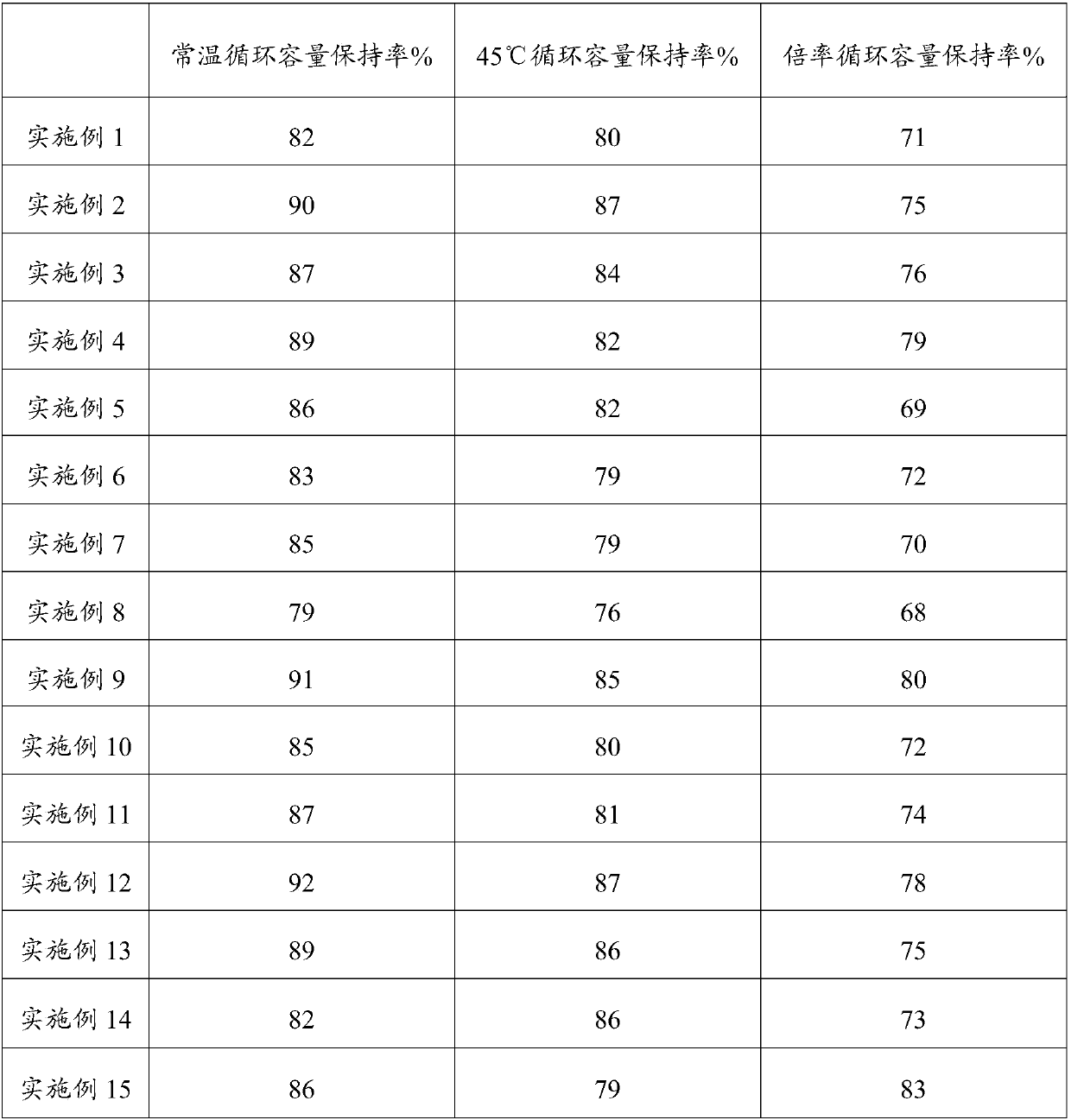

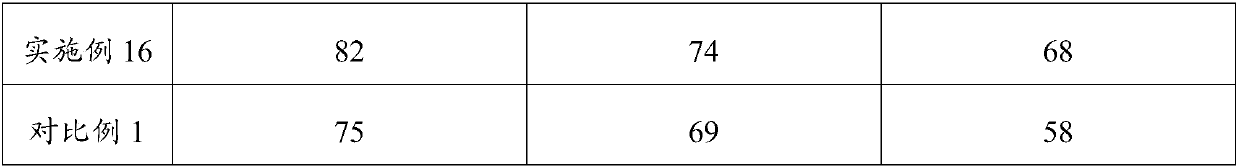

Examples

preparation example Construction

[0043] Correspondingly, the present invention provides a kind of preparation method of lithium ion battery electrode, comprises the following steps:

[0044] Coating the slurry including the additive on the current collector, drying and rolling to obtain a lithium-ion battery electrode; the additive is a fluorophosphate represented by formula I;

[0045] m a PO x f y Formula I;

[0046] Wherein, M is an alkali metal element, 0<a≤3, x and y are both integers, 1≤x, y≤4, x+y≤5.

[0047] The embodiment of the present invention firstly provides a slurry including an additive, the additive is a fluorophosphate represented by formula I, the content of which is as described above, and will not be repeated here. In an embodiment of the present invention, the slurry includes an active material, a conductive agent and a binder, and the contents of these components are also as described above. The slurry also includes a solvent, such as an organic solvent or water, for dispersing or...

Embodiment approach

[0055] In an embodiment of the present invention, the separator can be selected from various separator layers used in lithium-ion batteries known to those skilled in the art, such as polyolefin microporous membrane (PP microporous membrane), polyethylene felt (PE felt ), glass fiber mat, superfine glass fiber paper or PP / PE / PP composite film. As a preferred embodiment, the separator is a PP / PE / PP composite film.

[0056] In an embodiment of the present invention, the electrolyte is a non-aqueous electrolyte containing lithium salt and a non-aqueous solvent. Wherein, the lithium salt can be lithium hexafluorophosphate (LiPF 6 ), lithium tetrafluoroborate, lithium hexafluoroarsenate, lithium perchlorate, lithium trifluoromethanesulfonate, lithium perfluorobutylsulfonate, lithium aluminate, lithium chloroaluminate, lithium fluorosulfonimide One or more of lithium fluorophosphate, lithium chloride and lithium iodide, preferably LiPF 6 . The non-aqueous solvent can be gamma-but...

Embodiment 1

[0062] 1. Preparation of the positive electrode: Add sodium difluorophosphate with a total positive electrode solid mass fraction of 3% in N-methylpyrrolidone (NMP) solvent and stir to dissolve, and 88% lithium cobaltate (LiCoO 2 ), 4% acetylene black as a conductive material, 5% binder polyvinylidene fluoride (PVDF) are added in the solution, stirred to make a uniform slurry, the solid content of the slurry is 55%, and the obtained slurry is coated with Clothed on both sides of aluminum foil with a thickness of 12 μm, dried at 120° C., rolled and cut to obtain the positive electrode.

[0063] 2. Preparation of the negative electrode: Artificial graphite (Shanshan Technology, SS1-P10) with a total negative solid mass fraction of 95%, 2% binder styrene-butadiene rubber latex (SBR), 1% binder carboxymethyl Cellulose (CMC), 2% conductive material SP and water were added into a disperser for mixing to make a slurry with a solid content of 35%. The obtained slurry was coated on both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com