Wastewater treatment integrated device and method for composite catalytic oxidation coupled biological filter

A composite catalytic oxidation coupling and biological filter technology, applied in the field of water treatment, can solve problems such as the inability to achieve ideal effects, and achieve the effects of improving catalytic oxidation efficiency and biological oxidation effect, improving effluent quality, and accelerating biological metabolic reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

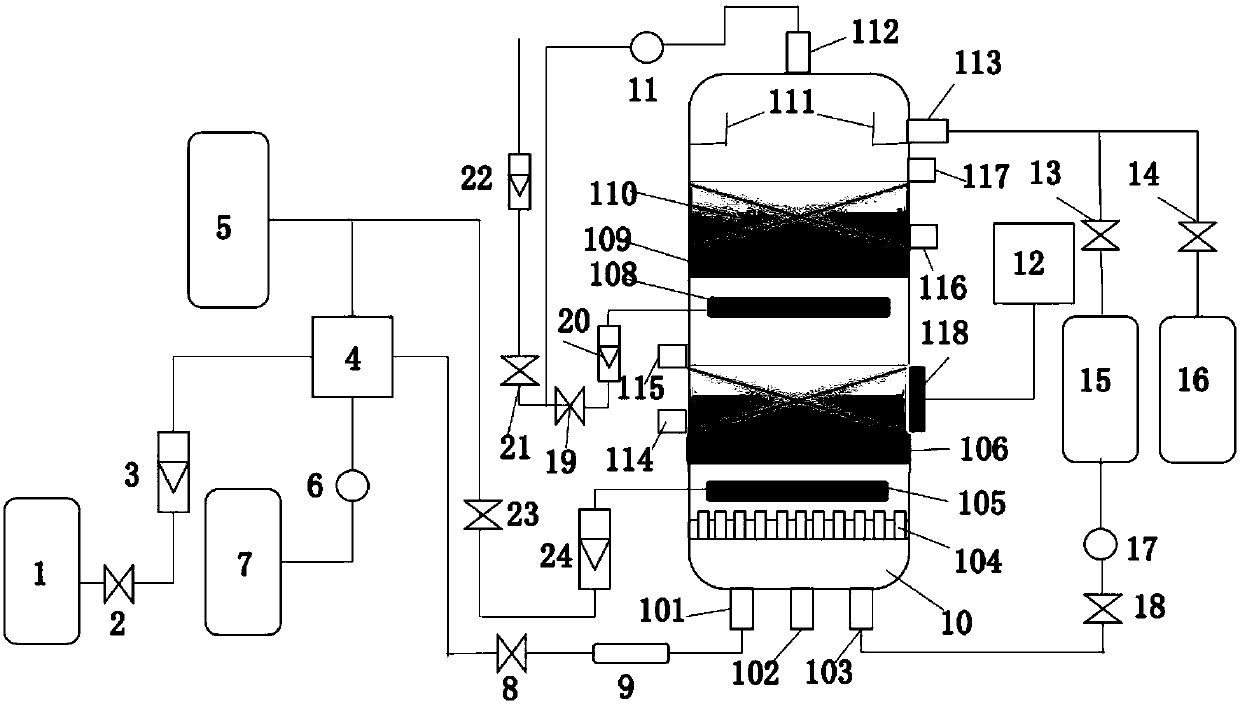

[0042] A composite catalytic oxidation coupled biological filter integrated device for refractory wastewater, comprising: a gas-liquid mixer 4, a composite catalytic oxidation coupled biological filter device 10, an energy field generator 12, and an ozone generator 5;

[0043] The liquid outlet of the gas-liquid mixer 4 is connected to the water inlet 101 of the composite catalytic oxidation coupling biofilter device 10, and the water inlet valve 8 and the dissolved air water release device 9 are arranged on the connecting pipeline, and the composite catalytic oxidation coupling The biological filter device 10 comprises a composite catalytic oxidation device (COX) at the lower end and a biological filter device (BF) at the upper end;

[0044] The composite catalytic oxidation device (COX) is provided with a water inlet 101, a water outlet 102, a backwash water inlet 103, a liquid distributor 104, a gas distributor 105, a catalyst support layer 106, a catalyst discharge outlet 1...

Embodiment 2

[0051] The above composite catalytic oxidation coupled biological filter integrated device is used to treat the raw water of printing and dyeing wastewater, and the conditions are as follows: raw water COD Cr =1000mg / L, pH=8.3, SS=250mg / L, before entering the above-mentioned disposal device, go through coagulation, air flotation and quartz sand filtration pretreatment, the experimental conditions are as follows: add 1000mg / L polyaluminum chloride and 5mg / L polyacrylamide, the coagulation reaction is 5 minutes, the air flotation reaction is 20 minutes, and the residence time of the quartz sand filter is 5 minutes.

[0052] After pretreatment by coagulation, air flotation and quartz sand filtration, the water quality indicators are as follows: COD Cr =460mg / L, pH=6.8, SS=8mg / L, the waste water after the above pretreatment enters the composite catalytic oxidation coupled biological filter integration device, the conditions are as follows: the influent flow rate is 0.1m 3 / h, in...

Embodiment 3

[0055] The composite catalytic oxidation coupling biofilter integrated device of Example 1 is used to treat the biochemical effluent of landfill leachate, and the conditions are as follows: the influent flow rate is 0.2m 3 / h, COD Cr =490mg / L, pH=7.8, in the ozone / oxygen gas mixture entering the gas-liquid mixer, the mixed gas flow rate is 20L / h, the ozone concentration is 150mg / L, and the amount of hydrogen peroxide added is 0.2L / h (according to the mass content of 27.5 % hydrogen peroxide), the MCM-41 molecular sieve particles of the catalyst carrier, the average particle diameter is 2.5mm, the catalyst active component is titanium dioxide, and the mass percentage of titanium is 1%. The height of the catalyst filled layer is 2m, the residence time of the wastewater in the catalyst filled layer is 60min, and the output power of the energy field generating device is 120W (ultrasonic power 60W, microwave power 60W). The biological filler is biological ceramsite, the particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com