A kind of high inorganic nutrient granular all-element bio-organic fertilizer and preparation method thereof

A bio-organic fertilizer and inorganic nutrient technology, applied in the direction of inorganic fertilizers, organic fertilizers, layered/coated fertilizers, etc., can solve the problems of not being able to add a large amount of inorganic nutrients, serious environmental pollution, and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of a high-inorganic nutrient granular whole-element bio-organic fertilizer by laboratory disc granulation

[0027] 1. Raw material pretreatment

[0028]Cow dung is used as organic material, and urban sludge and crop straw are fermented and decomposed by semi-permeable membrane-covered compost. Inorganic raw materials, animal fats, and adhesives are all purchased from the market, and various raw materials are crushed and processed separately. Sieve, the microbial powder is the bacterial powder prepared by spray drying after liquid fermentation of Bacillus amyloliquefaciens in a fermenter, and the effective number of viable bacteria is 21.5 billion / g.

[0029] 2. Measuring and mixing

[0030] Whole-element bio-organic fertilizer, by weight, the formula is as follows: 175.0% organic material decomposed cow dung, 22.5% urea, 12.0% monoammonium phosphate, 12.5% potassium sulfate, 5.0% calcium magnesium phosphate fertilizer, 5.0% clay, animal oil 0.35...

Embodiment 2

[0042] Example 2 Preparation of a high-inorganic nutrient granular whole-element bio-organic fertilizer by drum granulation

[0043] 1. Raw material pretreatment

[0044] Cow dung is used as organic material, and urban sludge and crop straw are fermented and decomposed by semi-permeable membrane-covered compost. Inorganic raw materials, animal fats, and adhesives are all purchased from the market, and various raw materials are crushed and processed separately. Sieve, the microbial bacterial powder is the Bacillus amyloliquefaciens bacterial powder purchased from Shandong Weilan Biotechnology Co., Ltd., and the effective number of viable bacteria is 200 billion / g.

[0045] 2. Ingredients and Mixing

[0046] All kinds of powdery raw materials and returned materials are poured into the raw material bin, sent to the raw material belt through the metering belt, meet with the system returned materials from the belt conveyor, and then sent to the raw material conveying belt, and the...

Embodiment 3

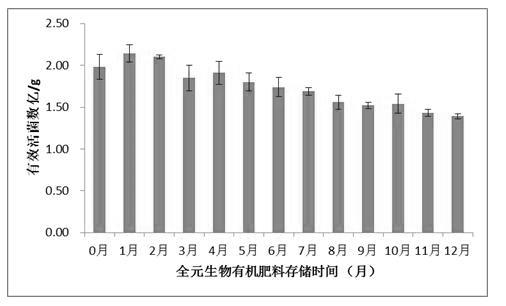

[0058] Example 3 Changes in the number of effective viable bacteria during storage of the whole element bio-organic fertilizer

[0059] In embodiment 1, the whole-element bio-organic fertilizer produced by the disc granulator is sealed and stored at room temperature, and the effective number of viable bacteria of the whole-element bio-organic fertilizer is tracked every other month. By adopting "NY / T In 2321-2013 Microbiological Fertilizer Product Inspection Regulations, 5.1 plate count method is used to determine the number of effective viable bacteria. Test results such as figure 2 .

[0060] The test results show that the two-time coating process and the adhesive powder adsorption process of the present invention can ensure the survival rate of microorganisms under the condition of high inorganic nutrients (20% to 30% of total nutrients, and the mass fraction of inorganic raw materials > 50%) , the number of effective viable bacteria decreased from the initial value of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com