Preparation method of special fertilizer for golden camellia

A special fertilizer and a technology for camellia tea, which is applied in the field of preparation of special fertilizers for camellia tea, can solve the problems of affecting growth and the inability of elements to be completely absorbed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

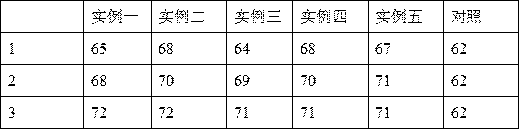

Examples

example 1

[0045] (1) Take 360kg of cotton straw with a moisture content of less than 15%, then cut or crush it, add 15kg of pitch-based carbon fiber, 3kg of boron nitride, 1kg of magnesium aluminum hydrotalcite and 15kg of corn starch into a carbonization furnace, and carbonize at 360°C After 40 minutes, the temperature was lowered to room temperature when the charcoal was produced, and then the charcoal was dried to obtain biochar;

[0046] (2) The mixed bacterial solution is obtained by the following methods:

[0047] a. Add 45kg of chicken manure into a fermenter equipped with fermented liquid, and ferment aerobically at 32°C for 48 hours to obtain chicken feces bacteria liquid; the composition of the fermented liquid is: 15 kg of soybean powder, 12 kg of starch, and 26 kg of molasses And dimethoxyethyl phthalate 3kg, water 60kg;

[0048] b. Insert the Bacillus subtilis strain into a fermenter equipped with a fermentation broth at an inoculum of 0.5%, and ferment aerobically at 35° ...

example 2

[0057] (1) Take 450kg of cotton straw with a moisture content below 15%, then cut or crush it, add 15kg of pitch-based carbon fiber, 3kg of boron nitride, 1kg of magnesium sulfate and 15kg of ammonium polyphosphate into the carbonization furnace, and carbonize at 400°C for 30min , when the charcoal is produced, the temperature is lowered to room temperature, and then the charcoal is dried to obtain biochar;

[0058] (2) The mixed bacterial solution is obtained by the following methods:

[0059] a. Add 60kg of chicken manure into a fermenter equipped with fermented liquid, and ferment aerobically at 38°C for 50 hours to obtain chicken manure bacterial liquid; the fermented liquid consists of 12 kg of soybean powder, 13 kg of wheat starch, and molasses 6kg and diethyl phthalate 2kg, water 60kg;

[0060] b. Insert the Bacillus subtilis strain into a fermenter equipped with a fermentation broth at an inoculation amount of 1.0%, and ferment aerobically at 35° C. for 30 hours to ob...

example 3

[0069] (1) Take 360kg of cotton straw with a moisture content of less than 15%, then cut or crush it, add 15kg of pitch-based carbon fiber, 3kg of boron nitride, 1kg of magnesium aluminum hydrotalcite and 15kg of corn starch into a carbonization furnace, and carbonize at 360°C After 40 minutes, the temperature was lowered to room temperature when the charcoal was produced, and then the charcoal was dried to obtain biochar;

[0070] (2) Grind sweet potato stalks (moisture less than 10%) with a plant grinder, pass through a 50-mesh sieve, take 100kg of sweet potato stalk powder, 0.7kg of diatomaceous earth and 0.6kg of ethyl p-methoxycinnamate, and add them to 300L In water, heat to 40°C, stir at constant temperature for 2 hours, filter the resulting suspension to obtain an extract, concentrate the filtrate to obtain a concentrate with a solid content of about 20%, then add 1.5kg of starch to the concentrate, and stir at 1000rpm After 0.5h, a suspension with uniform properties w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com