Collaborative extraction system of magnesium and lithium in salt lake brine and treatment method thereof

A technology of salt lake brine and extraction system, applied in the direction of improving process efficiency, etc., can solve the problems of difficult regeneration, loss of extractant, low yield, etc., and achieve the effect of high-value utilization and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

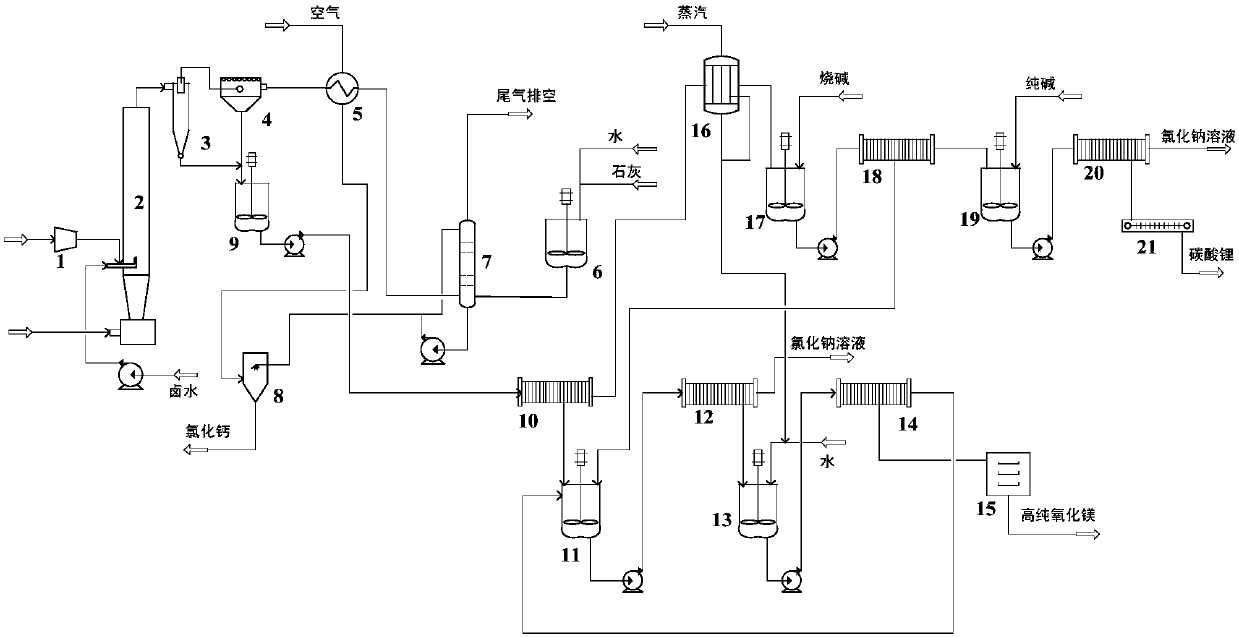

[0105] This embodiment provides a kind of synergistic extraction system of magnesium and lithium in salt lake brine, such as figure 1 As shown, the cooperative extraction system mainly includes a spray roasting system, a dust removal system, a pulp washing device 9, a plate and frame filter press 10, a magnesium extracting unit, a lithium extracting unit and a flue gas treatment system; wherein, the spray roasting system The material outlet of the dust removal system is connected with the material inlet of the dust removal system, the flue gas outlet of the dust removal system is connected with the gas inlet of the flue gas treatment system, and the solid material outlet of the dust removal system is connected with the pulp washing device 9 in turn. Link to each other with the plate and frame filter press 10, the solid material outlet of the plate and frame filter press 10 is connected with the material inlet of the described magnesium extraction unit, the liquid outlet of the ...

Embodiment 2

[0113] This embodiment provides a system for synergistic extraction of magnesium and lithium in salt lake brine. The device and connection of the system refer to Embodiment 1, the only difference is that the air compressor 1 is a piston compressor, and the cyclone The separator 3 is a multi-tube dust collector, and the pumps are all reciprocating pumps.

Embodiment 3

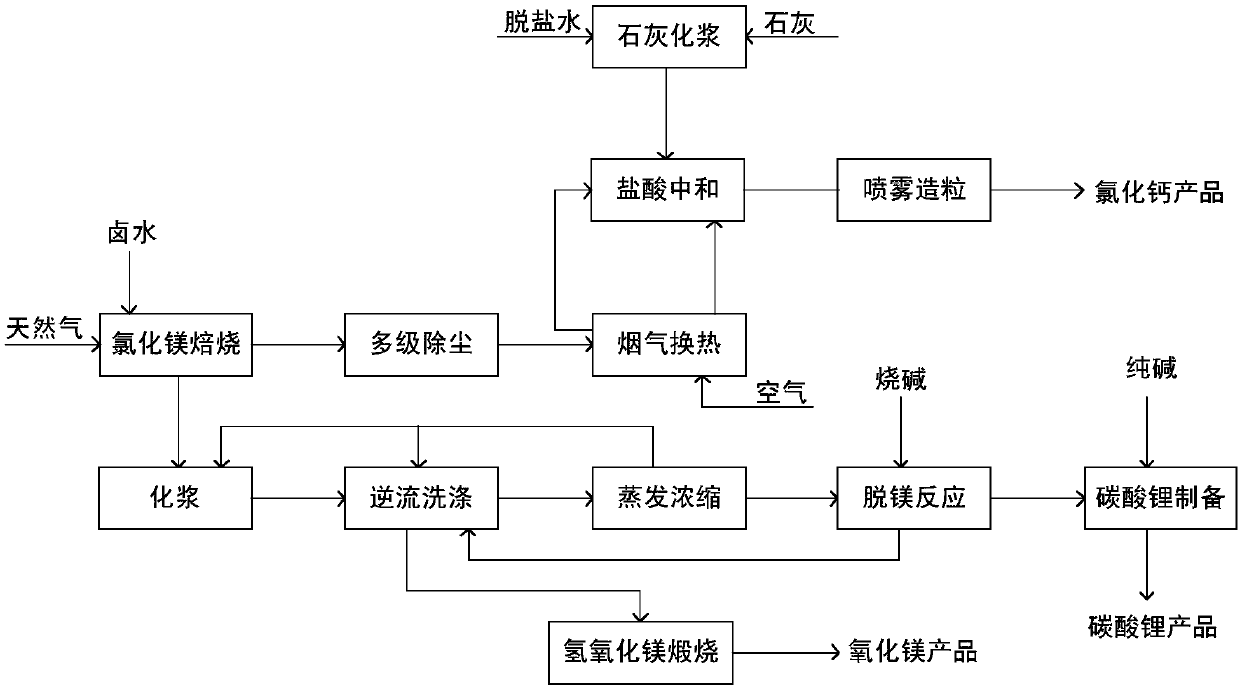

[0115] This embodiment provides a method for synergistic extraction of magnesium and lithium in salt lake brine, said method is carried out using the system in Example 1, and its process flow is as follows figure 2 As shown, the processing method includes the following steps:

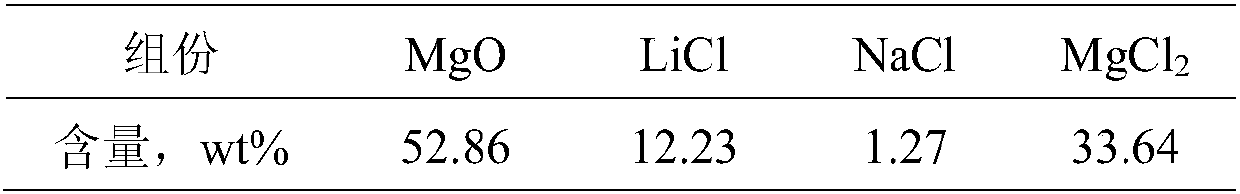

[0116] (I) Set the feed amount to 1m 3 / h, the temperature is 30°C, the magnesium content is 80g / L, the lithium content is 4g / L, the sodium content is 1g / L, the chlorine content is 260g / L salt lake brine and the pressure is 0.4Mpa, the temperature is 30°C compression The air enters the spray roasting tower 2 under the heat provided by natural gas for roasting, in which the volume ratio of compressed air to salt lake brine is 120:1, the bottom temperature of the spray roasting tower 2 is 600°C, and the top temperature is 350°C, and the materials stay in the tower The time is 2s, the temperature of the material at the top outlet of the spray roasting tower 2 is 300°C, and it enters the cyclone separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com