Biomass Ash Resource Utilization Method

A biomass ash and resource recovery technology, applied in the field of solid waste resource utilization, can solve the problems of low molecular sieve quality, neglect of pollution, and inability to fully extract, so as to improve the yield of a single kettle, reduce environmental pollution, The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

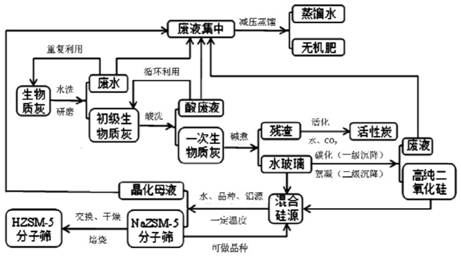

[0046] The specific process flow of biomass ash resource utilization method is as follows: figure 1 Shown:

[0047] 1) Soak a certain amount of finely ground biomass ash in deionized water (solid-to-liquid ratio 1:10) for 1 hour, then filter and dry to obtain about 9.5g of primary biomass ash;

[0048] 2) Mix the primary biomass ash and 1.5mol / L nitric acid in a mass ratio of 1:10, react at 60°C for 2 hours, filter, wash and dry to obtain primary biomass ash and primary acid waste liquid (acid liquid recycling);

[0049] 3) Mix the primary biomass ash with 2mol / L potassium hydroxide at a mass ratio of 1:10, react at 90°C for 2 hours, and obtain water glass and residue after filtration (high-quality activated carbon can be obtained after acid washing and activation of the residue);

[0050] 4) Take part of the water glass and inject carbon dioxide until the pH value of the solution is 10, then add a flocculant (the mass ratio of the flocculant to the solution is 1:60) until th...

Embodiment 2

[0059] Front steps 1)~5) are identical with embodiment 1;

[0060] 6) Mix water glass and nano-silicon dioxide in a certain proportion as a silicon source, and add a certain amount of aluminum source, deionized water and seed crystals (counted as CrSd) respectively, and the molar ratio of the synthetic molecular sieve is 1SiO 2 :0.01Al 2 o 3 :0.15OH - :10H 2 O:xCrSd (please write down the specific value of X), mix water glass and silicon dioxide in a certain proportion (liquid-solid mass ratio L / S=0.3), add deionized water, alumina and CrSd, CrSd / SiO 2 =0.06 (wherein the SiO in the seed crystal and the silicon source 2 mass ratio), and stirred at 60°C for 4h, crystallized in a reaction kettle at a temperature of 160°C, and crystallization time of 30h, filtered, washed and dried to obtain a porous ZSM-5 molecular sieve;

[0061] Step 7) is the same as in Example 1.

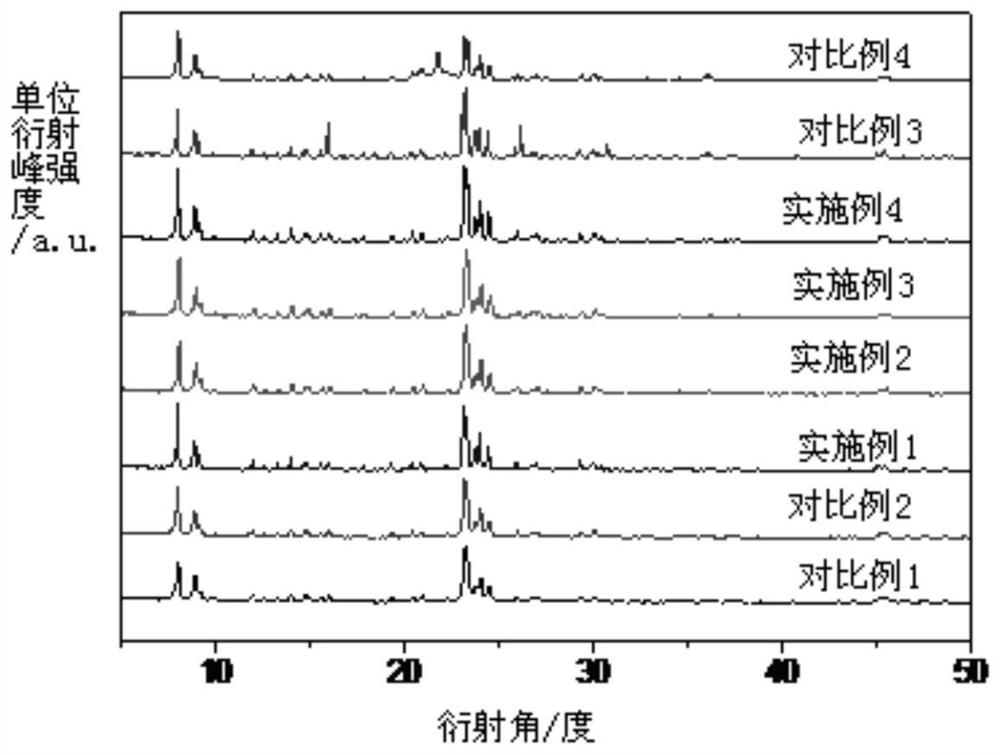

[0062] The XRD pattern of the crystallization product of embodiment 2 is shown in figure 2 . The relati...

Embodiment 3

[0064] Front steps 1)~5) are identical with embodiment 1;

[0065]7) Mix water glass and nano-silicon dioxide in a certain proportion as a silicon source, and add a certain amount of aluminum source, deionized water and seed crystals (counted as CrSd) respectively, and the molar ratio of the synthetic molecular sieve is 1SiO 2 :0.01Al 2 o 3 :0.15OH - :10H 2 O:xCrSd (please write down the specific value of X), mix water glass and silicon dioxide in a certain proportion (liquid-solid mass ratio L / S=0.7), add deionized water, alumina and CrSd, CrSd / SiO 2 =0.02 (wherein the SiO in the seed crystal and the silicon source 2 mass ratio), and stirred at 60°C for 4h, crystallized in a reaction kettle at a temperature of 160°C, and crystallization time of 30h, filtered, washed and dried to obtain a porous ZSM-5 molecular sieve;

[0066] Step 7) is the same as in Example 1.

[0067] The XRD pattern of the crystallization product of embodiment 3 is shown in figure 2 . The relativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com