Andrographolide enteric-coated granule capable of being accurately dissolved out and preparation method

A technology of Yanhuning intestinal and Yanhuning, which is applied in the field of Yanhuning enteric-coated granules and its preparation, can solve the problems of easily causing allergic reactions or pyrogen-like reactions, not being universally applicable, and pyridine easily causing side effects, etc., to achieve Increase the difficulty of quality control, improve the uniformity and reproducibility, and reduce the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of refined Yanhuning

[0028] Commercially available Chuanhuning is used for esterification reaction with sodium sulfite, and then directly synthesized with sodium bicarbonate and potassium bicarbonate or in a specific ratio to reduce repeated drying, dissolution, heating and other processes. The specific preparation method is as follows: using andrographis paniculata as a raw material, adding anhydrous sodium sulfite and 90% ethanol into an extraction tank, while protecting with nitrogen, stirring and mixing, heating in a water bath, and controlling the temperature at 60°C. Stop heating after the raw materials are dissolved, and slowly add 19% KHCO dropwise 3 And 10% Na 2 CO 3 Mixed solution (mixed by mass ratio 1:1) to produce CO 2 Gas, crystals are precipitated in the reaction liquid, wait for CO 2 After the production is completed, heat to dissolve in a water bath at a temperature of about 60°C, and then add an appropriate amount of absolute ethan...

Embodiment 2

[0029] Example 2: Preferable isolation layer material

[0030] (1) The mass fractions of Yanhuning enteric-coated pellets are shown in Table 1.

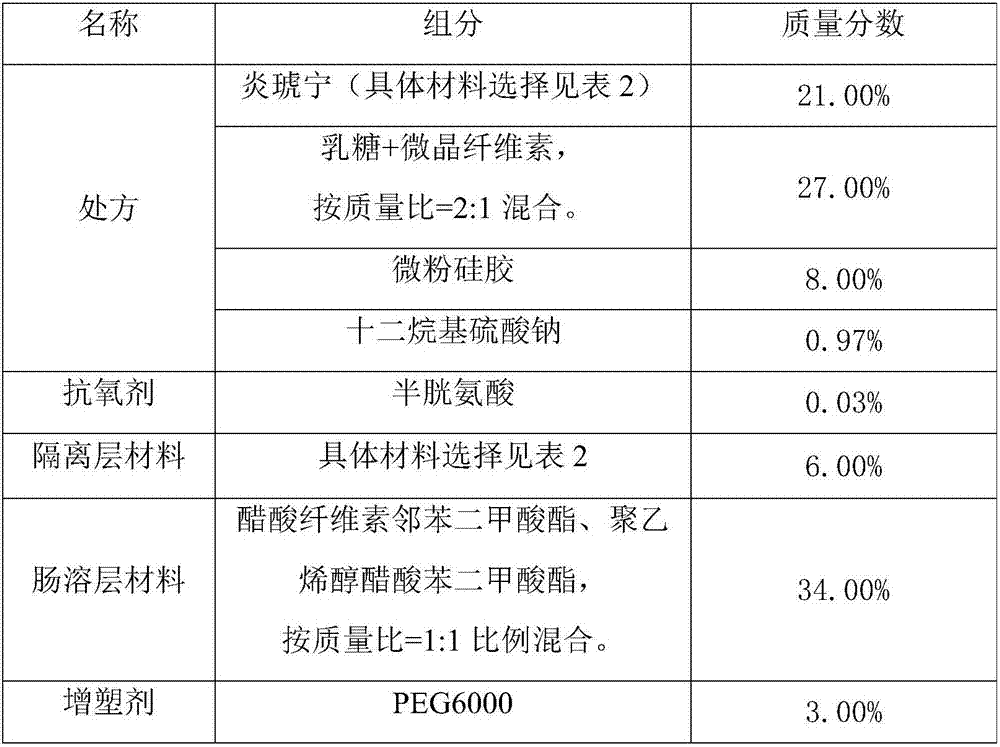

[0031] Table 1 Yanhuning enteric-coated pellets prescription

[0032]

[0033] As the mixture of lactose and microcrystalline cellulose is prepared at a mass ratio of 2:1, the ratio of 2:1 is selected throughout the text for the convenience of operation. In actual operation, lactose: microcrystalline cellulose=1:1~3:1 can be used. If it exceeds this ratio, the lactose is too high, which may cause difficulties in pelletizing and tableting in the later stage.

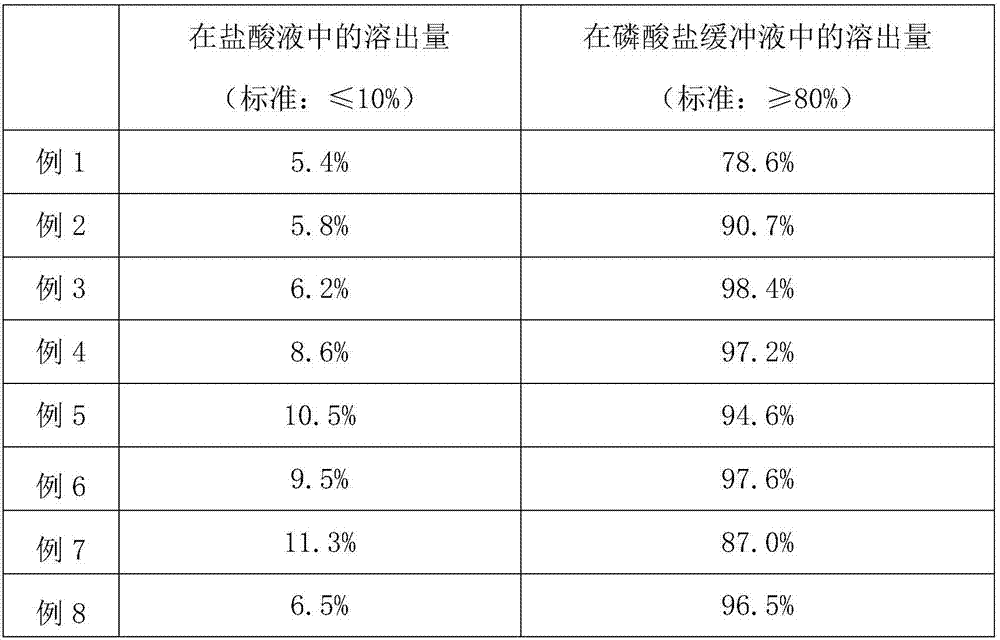

[0034] (2) Based on the mass scores of each group in Table 1, select Yanhuning with different precisions and isolation layer materials with different materials and different mass ratios to screen Yanhuning and isolation layer materials. The specific choices are as follows Table 2 shows.

[0035] Table 2 Selection of Yanhuning and isolation layer materials

[0036]

[0037] (3) Coating o...

Embodiment 3

[0049] Example 3: Yanhuning enteric-coated pellets prescription and preparation method

[0050] (1) The formula of Yanhuning enteric-coated pellets is shown in Table 4.

[0051] Table 4 Yanhuning enteric-coated pellets prescription

[0052]

[0053]

[0054] (2) The refined Yanhuning was prepared according to the method of Example 1, with an accuracy of 99.5%.

[0055] (3) Coating of isolation layer. Mix the material of the isolation layer with purified water or 80% ethanol aqueous solution to prepare a solution with a solid content of 5%, and then add the antioxidant cysteine to prepare a solution with a solid content of 5% (in order to control product quality, The solid content needs to be controlled within 3%-15%), and stir evenly with an air pump mixer. Pass Yanhuning, lactose, microcrystalline cellulose, and micro-powdered silica gel through a 200-mesh sieve, and add them to a high-speed centrifugal granulating coating machine to directly coat the isolation layer to reduce th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com