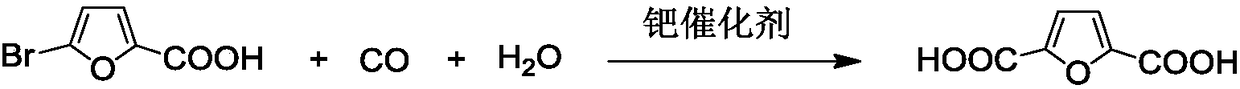

Method for preparing 2,5-furandicarboxylicacid (FDCA) by catalytic carbonylation

A technology of furandicarboxylic acid and palladium catalyst, applied in the direction of organic chemistry and the like, can solve problems such as consumption of human food resources, and achieve the effects of great application value and prospect, mild reaction conditions and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Palladium chloride (50.0 mg, 0.28 mmol) and 4,5-bisdiphenylphosphine-9,9-dimethylxanthene (161.8 mg, 0.28 mmol) were sequentially charged into a pressure-resistant Schlenk test tube. , potassium carbonate (1.52 g, 11 mmol), water (4.96 g, 275 mmol), 5-bromo-2-furoic acid (1.04 g, 5.5 mmol) and 10 ml of 1,4-dioxane, The system is evacuated and replaced three times with carbon monoxide (in the sealed atmosphere formed by the last replacement, the pressure of carbon monoxide is 1 standard atmospheric pressure), and the temperature is maintained at 90 degrees Celsius for 6 hours. After cooling down to room temperature, the raw material is converted by liquid phase analysis. The yield is 100%, the FDCA yield is 99%, and the selectivity is 99%. The pH of the reaction solution was adjusted to 1 with hydrochloric acid solution, and then filtered, washed with ice water, and dried to obtain 2,5-furandicarboxylic acid (0.79 g, 5.06 mmol), with a yield of 92%.

Embodiment 2

[0033] Palladium chloride (50.0 mg, 0.28 mmol), 1,3-bis(diphenylphosphine) propane (115.5 mg, 0.28 mmol), potassium bicarbonate (1.65 g, 16.5 mmol), water (2.48 g, 137.5 mmol), 5-bromo-2-furoic acid (1.04 g, 5.5 mmol) and 10 milliliters of DMSO, the system was evacuated and replaced three times with carbon monoxide (the last replacement In the formed sealed atmosphere environment, the pressure of carbon monoxide is 1 standard atmospheric pressure), and the temperature is maintained at 90 degrees Celsius for 12 hours. After cooling down to room temperature, the conversion rate of raw materials is 95%, the FDCA yield is 90%, and the selectivity is 95%. . The pH of the reaction solution was adjusted to 2 with sulfuric acid solution, and then filtered, washed with ice water, and dried to obtain 2,5-furandicarboxylic acid (0.70 g, 4.51 mmol), with a yield of 82%.

Embodiment 3

[0035] [1,1'-bis(diphenylphosphino)ferrocene]palladium dichloride (140.0 mg, 0.28 mmol), potassium bicarbonate (1.65 g, 16.5 mmol), water (2.48 g, 137.5 millimol) and 5-bromo-2-furoic acid (1.04 g, 5.5 mmol) were added successively in 10 milliliters of ethylene glycol diethyl ether, and the reaction system was placed in a stainless steel autoclave with a polytetrafluoroethylene lining inside. Introduce carbon monoxide at 30 standard atmospheric pressure, keep the temperature at 110 degrees centigrade and react for 6 hours. After cooling down to room temperature, the conversion rate of raw materials is 100%, the yield of FDCA is 97%, and the selectivity is 97%. The pH of the reaction solution was adjusted to 2 with sulfuric acid solution, and then filtered, washed with ice water, and dried to obtain 2,5-furandicarboxylic acid (0.81 g, 5.17 mmol), with a yield of 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com