Lithium ion battery electrode sheet and preparation method thereof

A technology for lithium ion batteries and electrode sheets, which is applied in battery electrodes, electrode manufacturing, electrode rolling/calendering, etc., to achieve the effect of simple and convenient process route, good electrical conductivity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

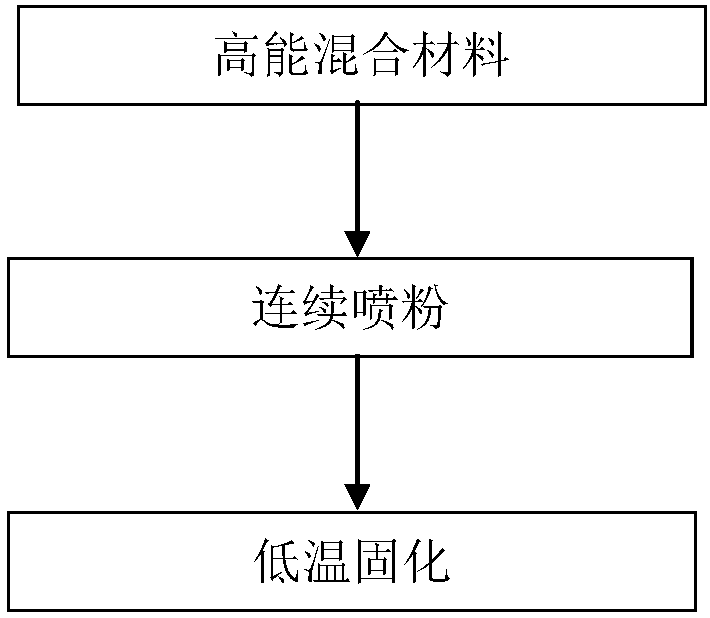

[0033] A preparation method of lithium-ion battery electrode pole piece:

[0034] 1. Under the condition of no solvent, a certain proportion of positive or negative active materials, polymer binders, solid electrolytes and other additives are mixed to obtain uniform powder materials. Among them, the positive or negative active materials The number of parts by weight is 80-95 parts, and the positive electrode active material can be selected from one or a combination of two or more of lithium cobaltate, lithium manganate, lithium iron phosphate, lithium vanadium phosphate, ternary materials or manganese-rich materials. The negative electrode active material can be selected from one, two or more combinations of two-dimensional materials such as graphite-based materials, silicon-based materials, tin-based materials, lithium titanate or graphene; the number of parts by weight of the polymer binder is 3 -10 parts, the polymer binder can be selected from one, two or more combinations...

Embodiment 1

[0038] 1. In a high-energy ball mill, mix 94% lithium cobalt oxide cathode material, 3% PVDF binder, 2% PVDF lithium salt electrolyte and 1% conductive carbon black for 30 minutes to obtain the required Uniform powder material; then use a low-pressure thermal spraying process to coat a layer of uniform powder layer with a thickness of 100 μm on the surface of the aluminum foil; then use a normal temperature laser sintering process to finally obtain a lithium cobalt oxide battery electrode pole piece. Record the thickness, porosity and 0.3C capacity of the lithium cobalt oxide battery electrode sheet obtained by this method, see No. 1-4 in Table 1.

[0039] 2. In the mixer, use the same ratio to use 94% lithium cobalt oxide cathode material, 3% PVDF binder, 2% PVDF lithium salt electrolyte and 1% conductive carbon black The organic solvent NMP is uniformly dispersed; then the lithium cobalt oxide battery electrode sheet is obtained through coating and rolling processes. Record...

Embodiment 2

[0043] 1. In the ultrasonic mixing equipment, the mass fraction of 90% lithium manganate cathode material, 5% Li 3OCl solid electrolyte and 5% graphene are mixed with high energy for 2 hours to obtain the required uniform powder material; then a layer of uniform powder layer with a thickness of 200 μm is coated on the surface of aluminum foil by high-pressure cold powder spraying process; then microwave curing process is used Finally, the lithium manganese oxide battery electrode pole piece is obtained. Record the thickness, porosity and 0.3C capacity of the lithium manganate battery electrode sheet obtained by this method, see No. 1-4 in Table 2.

[0044] 2. In the ultrasonic mixing equipment, under the same ratio, the lithium manganate cathode material with a mass fraction of 90%, and 5% Li 3 OCl solid state electrolyte and 5% graphene are uniformly dispersed with organic solvent NMP; then the lithium manganate battery electrode sheet is obtained through coating and rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com