Antibacterial nanofiber membrane and preparation method thereof

A nanofiber membrane and fiber membrane technology, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of unfavorable production and promotion, difficult cost control, high price, etc., to improve antibacterial effectiveness and broad spectrum , low price, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

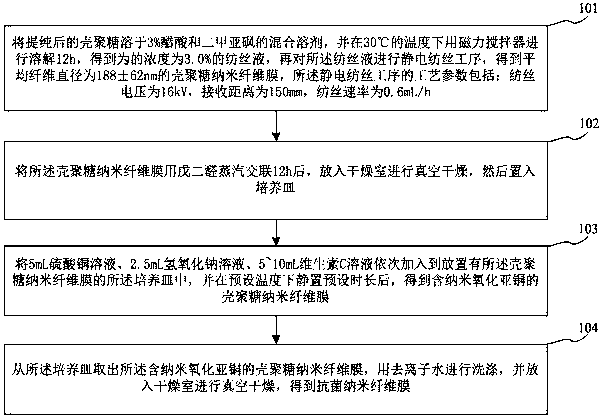

[0022] figure 1 It is a method flowchart of a method for preparing an antibacterial nanofiber membrane shown according to an exemplary embodiment, and the method includes:

[0023] Step 101, dissolving the purified chitosan in a mixed solvent of 3% acetic acid and dimethyl sulfoxide, and dissolving it with a magnetic stirrer at a temperature of 30° C. for 12 hours to obtain a spinning solution with a concentration of 3.0%. , then carry out electrospinning process to described spinning solution, obtain the chitosan nanofiber membrane that average fiber diameter is 188 ± 62nm, the process parameter of described electrospinning process comprises: spinning voltage is 16kV, and receiving distance is 150mm, the spinning rate is 0.6mL / h.

[0024] Step 102, after crosslinking the chitosan nanofiber membrane with glutaraldehyde vapor for 12 hours, put it into a drying room for vacuum drying, and then put it into a petri dish.

[0025] The chitosan nanofiber membrane after crosslinkin...

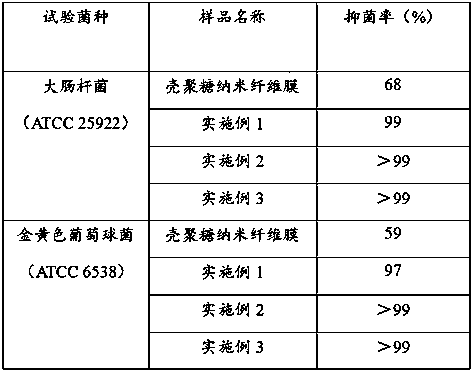

Embodiment 1

[0039] (1) Dissolve the purified chitosan in a mixed solvent of 3% acetic acid and dimethyl sulfoxide, and dissolve it with a magnetic stirrer at a temperature of 30°C for 12 hours to obtain a spinning solution with a concentration of 3.0%. , then carry out electrospinning process to described spinning solution, obtain the chitosan nanofiber membrane that average fiber diameter is 188 ± 62nm, the process parameter of described electrospinning process comprises: spinning voltage is 16kV, and receiving distance is 150mm, the spinning rate is 0.6mL / h.

[0040] (2) After cross-linking the chitosan nanofiber membrane with glutaraldehyde vapor for 12 hours, put it into a drying room for vacuum drying, and then put it into a petri dish.

[0041](3) The copper sulfate solution of 5mL0.02mol / L, the sodium hydroxide solution of 2.5mL0.2mol / L, the vitamin C solution of 5mL0.04mol / L are sequentially added to the place where the chitosan nanofiber membrane is placed. In the above petri di...

Embodiment 2

[0044] (1) Dissolve the purified chitosan in a mixed solvent of 3% acetic acid and dimethyl sulfoxide, and dissolve it with a magnetic stirrer at a temperature of 30°C for 12 hours to obtain a spinning solution with a concentration of 3.0%. , then carry out electrospinning process to described spinning solution, obtain the chitosan nanofiber membrane that average fiber diameter is 188 ± 62nm, the process parameter of described electrospinning process comprises: spinning voltage is 16kV, and receiving distance is 150mm, the spinning rate is 0.6mL / h.

[0045] (2) After cross-linking the chitosan nanofiber membrane with glutaraldehyde vapor for 12 hours, put it into a drying room for vacuum drying, and then put it into a petri dish.

[0046] (3) The copper sulfate solution of 5mL0.02mol / L, the sodium hydroxide solution of 2.5mL0.2mol / L, the vitamin C solution of 5mL0.04mol / L are sequentially added to the place where the chitosan nanofiber membrane is placed. In the petri dish, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com