Application of hydroxyethyl starch in making wound dressing

A technology of hydroxyethyl starch and hydroxyethyl, applied in the field of sanitary materials, can solve the problems of unable to form a colloid protective layer, unable to effectively protect the wound surface, unable to absorb quickly, etc. The effect of promoting increased activity of the gastrointestinal tract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

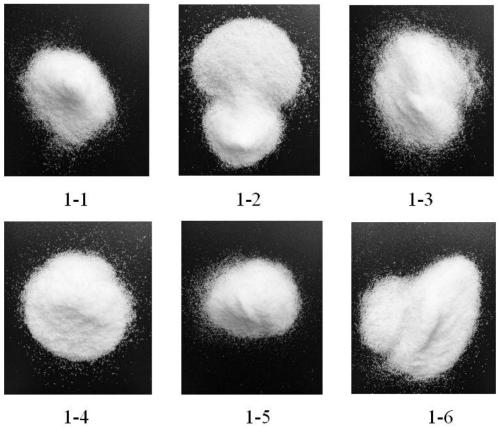

[0069] Weigh hydroxyethyl starch, sodium alginate and calcium chloride according to Table 1. The molecular weight of hydroxyethyl starch is 135,000 Da, the molecular weight of sodium alginate is 6000 Da, and the G / M ratio is 1.50. Sodium alginate and hydroxyethyl starch The particle size is 60 mesh; the above raw materials are added to the boiling granulator preheated to 70℃, the fan of the boiling granulator is started, and the wind speed of the boiling granulator is controlled to 25HZ to make the material in a fluidized state.

[0070] Table 1

[0071] Numbering Hydroxyethyl starch (g) Sodium Alginate (g) Calcium chloride (g) 1-110020000 1-2200120050 1-320080010 1-450030020 1-530090040 1-6400100030

[0072] Add 100g of deionized water to the boiling granulator through the spray gun for granulation, control the motor speed of the spray gun to 200rpm, the pressure 0.2MPa, and control the wind speed of the boiling granulator to 25HZ to make hydroxyethyl starch, sodium alginate, ...

Embodiment 2

[0074] Weigh 500g of hydroxyethyl starch, 1000g of water-soluble chitosan, pH of 1% aqueous solution of water-soluble chitosan is 6.5, degree of deacetylation is 95%, molecular weight of hydroxyethyl starch is 280,000 Da, add it to preheat to 70℃ In the boiling granulator, start the fan of the boiling granulator, and control the wind speed of the boiling granulator to 75HZ to make the material in a fluidized state.

[0075] Add 100g of deionized water to the boiling granulator through the spray gun for granulation, control the motor speed of the spray gun to 200rpm, the pressure 0.2MPa, and control the wind speed of the boiling granulator to 75HZ to make the hydroxyethyl starch and water-soluble shell The sugar and water are mixed and granulated. The inlet temperature of the granulator is controlled to be 90°C, the outlet temperature is 50°C, and the boiling granulation time is 2 minutes.

[0076] Pack and seal the granulated wound dressing. Put the wound dressing to be sterilized...

Embodiment 3

[0078] Weigh 1000g of absorbing oxidized cellulose, 5000g of hydroxyethyl starch, and 100g of β-glucan into the boiling granulator preheated to 70℃. The degree of polymerization of oxidized cellulose can be absorbed is 400, and oxidized cellulose can be absorbed. The carboxyl group content in the hydroxyethyl starch is 22%, and the molecular weight of the hydroxyethyl starch is 500,000 Da; the fan of the boiling granulator is started, and the wind speed of the boiling granulator is controlled to 60HZ to make the material in a fluidized state.

[0079] Add 1000g of deionized water to the boiling granulator through the spray gun for granulation, control the motor speed of the spray gun to 200rpm, the pressure 0.2MPa, and control the wind speed of the boiling granulator 60HZ to make the hydroxyethyl starch and absorb the oxidized fiber For granulation, the inlet temperature of the granulator is 74℃, the outlet temperature is 48℃, and the boiling granulation time is 8min. Use a three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com