Preparation method of metal nanoparticles

A metal nanoparticle, metal technology, applied in nanotechnology and other directions, can solve the problems of uncontrollable particle size, complex experimental equipment, high raw material cost, achieve uniform and controllable particle size, expand the scope of application, and simple operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

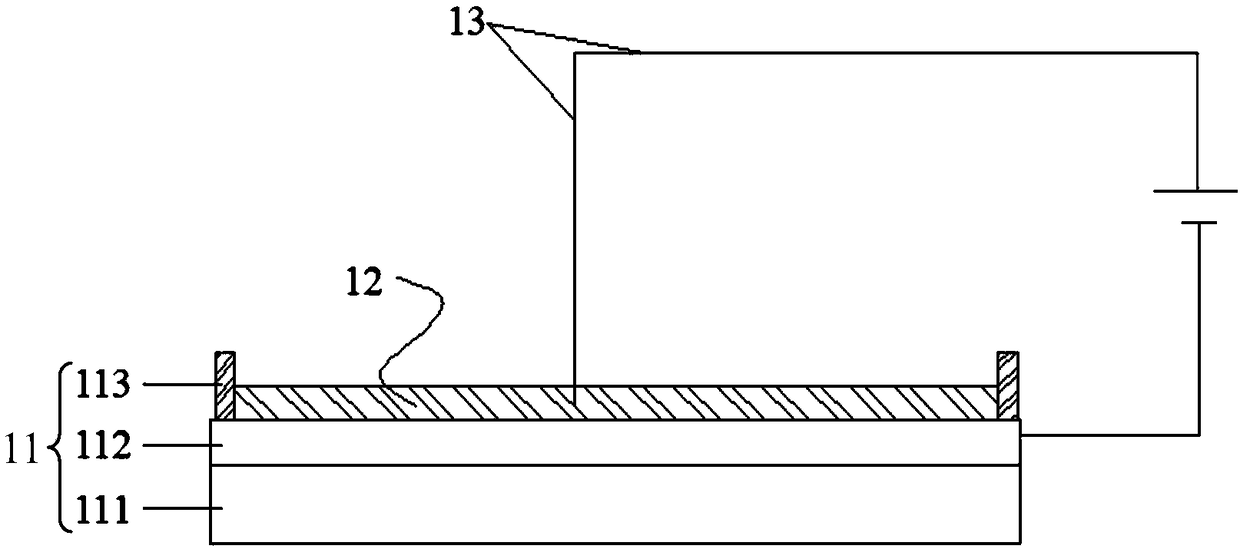

[0042] see figure 1 , this embodiment is as in figure 1 Metal nanoparticles are prepared in the shown preparation device, and the preparation process includes the following steps:

[0043] Preparation of the reaction cell 11: Take the glass substrate 111, ultrasonically clean the glass substrate 111 in acetone, ethanol, and deionized water for 15 minutes, blow dry with nitrogen, and coat a layer of crystalline indium on the glass substrate 111 by sol-gel method Tin oxide film 112, using acrylate polymer material to form a cofferdam structure 113 around the crystalline indium tin oxide film 112;

[0044] Add deionized water 12 in the above reaction tank;

[0045] Connect the power supply, the deionized water 12 is connected to the positive pole of the power supply through the tungsten wire 13, the negative pole of the power supply is connected to the crystalline indium tin oxide film 112, and the power is turned on for electrolysis. The thickness of the indium tin oxide film ...

Embodiment 2

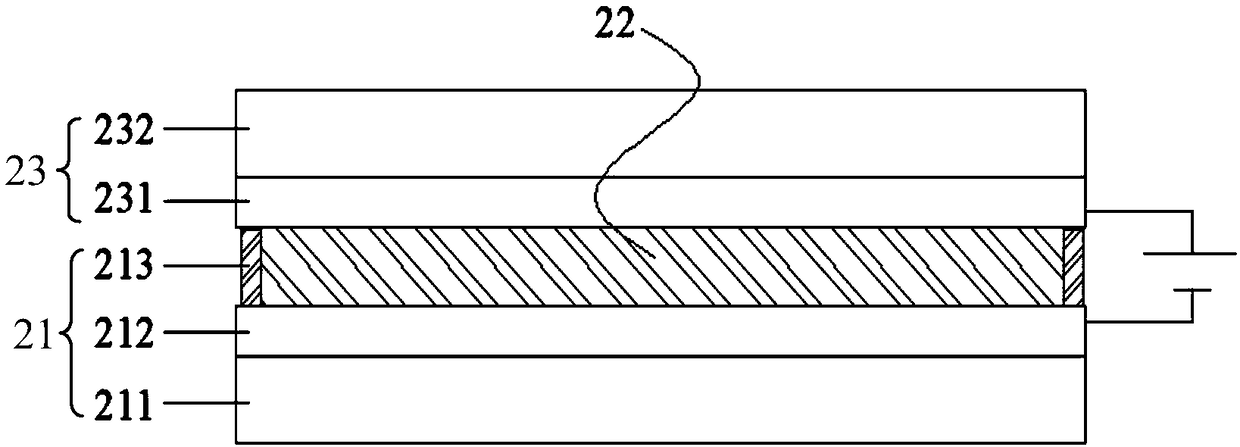

[0051] see image 3 , this embodiment is as in image 3 Indium nanoparticles are prepared in the shown preparation device, and the preparation process includes the following steps:

[0052] Prepare the reaction cell 21: take the quartz substrate 211, ultrasonically clean the quartz substrate 211 in acetone, ethanol, and deionized water for 15 minutes in sequence, blow dry with nitrogen, and coat a layer of crystalline silicon dioxide on the quartz substrate 211 by chemical vapor deposition. The indium tin oxide film 212 is made into a cofferdam structure 213 around the crystalline indium tin oxide film 212 with a water-soluble pressure-sensitive adhesive;

[0053] Add 0.1M NaCl solution 22 into the above reaction pool;

[0054] Connect the power supply, the 0.1M NaCl solution 22 is connected to the positive pole of the power supply through the substrate 23 with the FTO conductive layer. 212. Turn on the power supply for electrolysis. The thickness of the indium tin oxide film...

Embodiment 3

[0056] This embodiment provides a method for preparing indium nanoparticles, comprising the following steps:

[0057] Prepare the reaction cell: take the silicon substrate, ultrasonically clean the silicon substrate in acetone, ethanol, and deionized water for 15 minutes, blow dry with nitrogen, and coat a layer of amorphous indium tin oxide on the silicon substrate by the homogeneous precipitation method. Thin film, using silica gel to make a cofferdam structure around the amorphous indium tin oxide film;

[0058] Add 0.1M NaOH solution to the above reaction pool;

[0059] Connect the power supply, 0.1M NaOH solution is connected to the positive electrode of the power supply through gold wire, and the negative electrode of the power supply is connected to the amorphous indium tin oxide film, and the power is turned on for electrolysis. The thickness of the indium tin oxide film is 25nm, and the applied electric field strength is 0.33V / μm, the electrolysis time is 1.5min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com