Broad-spectrum VOCs (Volatile Organic Compounds) catalytic combustion monolithic catalyst as well as preparation method and application thereof

A monolithic catalyst and catalytic combustion technology, applied in the direction of catalyst activation/preparation, combustion method, physical/chemical process catalyst, etc., can solve the problems of environmental secondary pollution, resource and energy waste, etc., and achieve improved utilization rate and flow resistance Effects of Low and Intensifying Interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

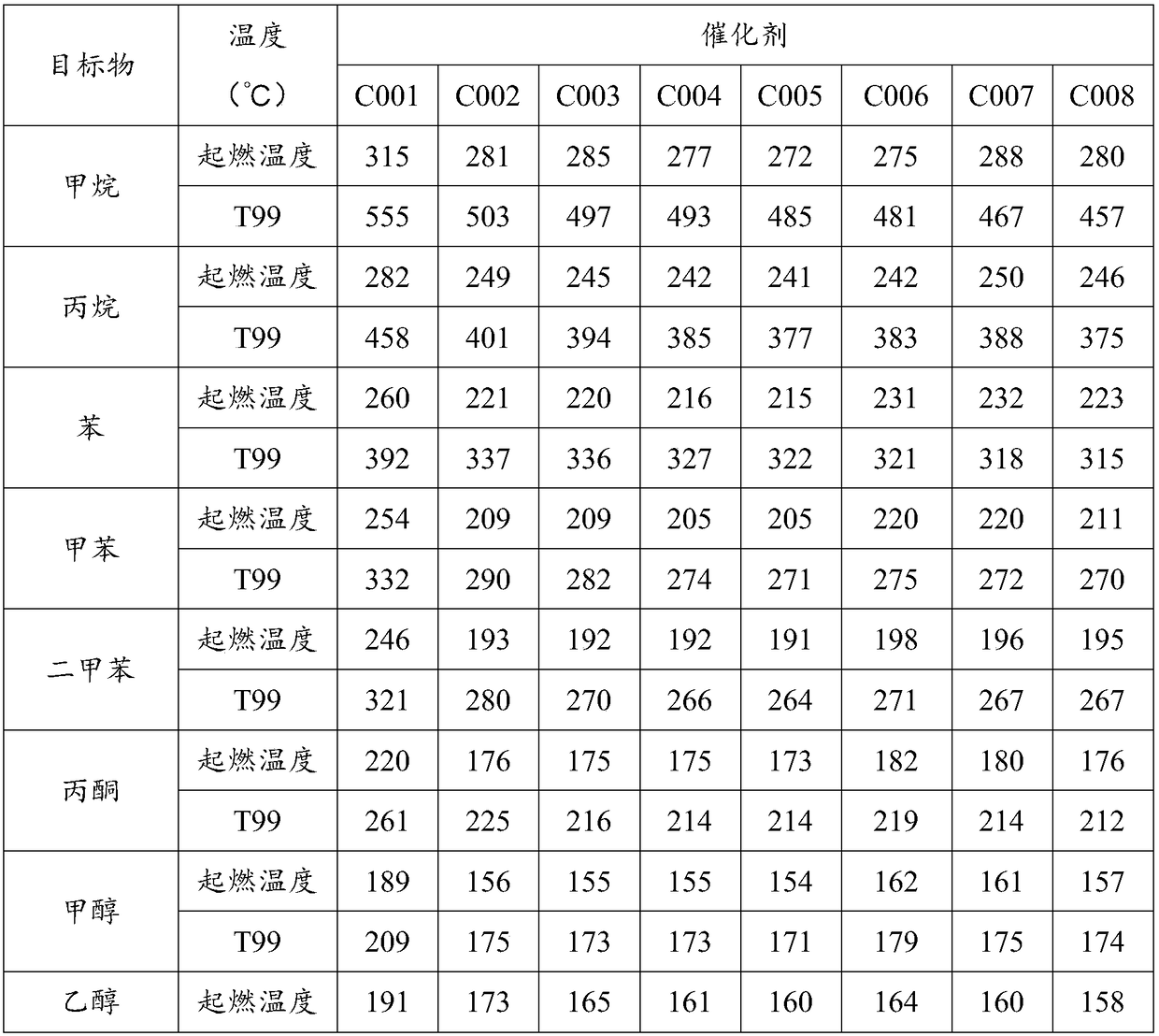

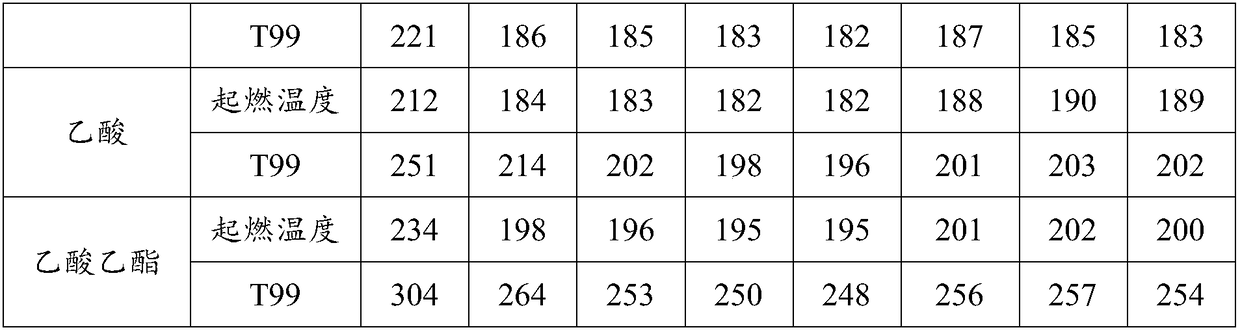

Examples

Embodiment 1

[0025] Weigh Ce-Zr-La-Y quaternary rare earth composite oxide 150g, high specific surface area (>200m 2 / g) Activated alumina 340g, 10g pseudoboehmite, water 500g and mix and stir, add nitric acid to adjust slurry pH=3, put it into a sand mill and wet grind for 0.5h to make coating slurry. Among them, the CeO in the quaternary rare earth composite oxide 2 , ZrO 2 , La 2 o 3 , Y 2 o 3 The mass contents are 80%, 10%, 2%, 8%, respectively. Put 300 holes / square inch of cordierite honeycomb ceramics into the prepared slurry until completely submerged, take out the honeycomb ceramics, use compressed air to blow off excess slurry inside the channels, then dry at 110°C for 2 hours, and calcined at 500°C for 8 hours A monolithic catalyst semi-finished product is obtained, wherein the additive coating content is 14.6%. Measure 2 mL of 5 mgPd / mL palladium nitrate aqueous solution, dilute it to 70 mL, weigh 100 g of the semi-finished monolithic catalyst and immerse it in the dilute...

Embodiment 2

[0027] Weigh Ce-Zr-La-Y quaternary rare earth composite oxide 160g, high specific surface area (>200m 2 / g) Activated alumina 230g, 10g boehmite, 600g water and mix and stir, add nitric acid to adjust slurry pH=4, put it into a sand mill and wet grind for 0.5h to make coating slurry. Among them, the CeO in the quaternary rare earth composite oxide 2 , ZrO 2 , La2 o 3 , Y 2 o 3 The mass content is respectively 30%, 55%, 5%, 10%. Put 200 holes / square inch of cordierite honeycomb ceramics into the prepared slurry until fully submerged, take out the honeycomb ceramics, use compressed air to blow off excess slurry inside the channels, then dry at 110°C for 2 hours, and calcined at 500°C for 2 hours A monolithic catalyst semi-finished product was obtained, wherein the additive coating content was 11.2%. Measure 6mL of 5mgPd / mL palladium nitrate aqueous solution, dilute it to 70mL, weigh 100g of the above monolithic catalyst semi-finished product and immerse it in the diluted p...

Embodiment 3

[0029] Weigh Ce-Zr-La-Pr quaternary rare earth composite oxide 150g, high specific surface area (>200m 2 / g) Activated alumina 130g, 20g pseudo-boehmite, 700g water and mix and stir, add nitric acid to adjust slurry pH=3.5, put it into sand mill and wet grind for 0.5h to make coating slurry. Among them, the CeO in the quaternary rare earth composite oxide 2 , ZrO 2 , La 2 o 3 、 Pr 6 o 11 The mass content is 10%, 80%, 6%, 4% respectively. Put the cordierite honeycomb ceramics with 400 holes / square inch into the prepared slurry until completely submerged, take out the honeycomb ceramics, use compressed air to blow off the excess slurry inside the channels, then dry at 110°C for 2 hours, and calcined at 600°C for 2 hours A monolithic catalyst semi-finished product was prepared, wherein the additive coating content was 7.5%. Measure 8 mL of 5 mgPd / mL palladium nitrate aqueous solution, dilute it to 70 mL, weigh 100 g of the above-mentioned monolithic catalyst semi-finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com