Novel functional coating and preparation method thereof

A technology of functional coatings and functional fillers, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of complex preparation process, high cost, no antibacterial properties, etc. The effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

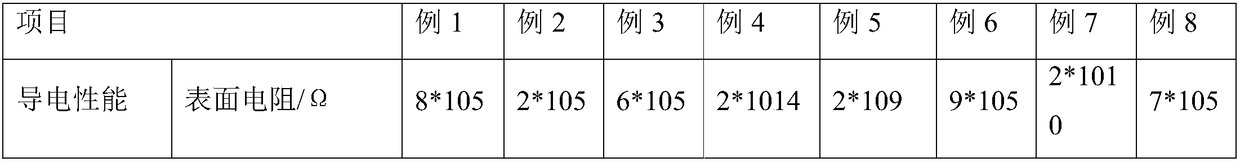

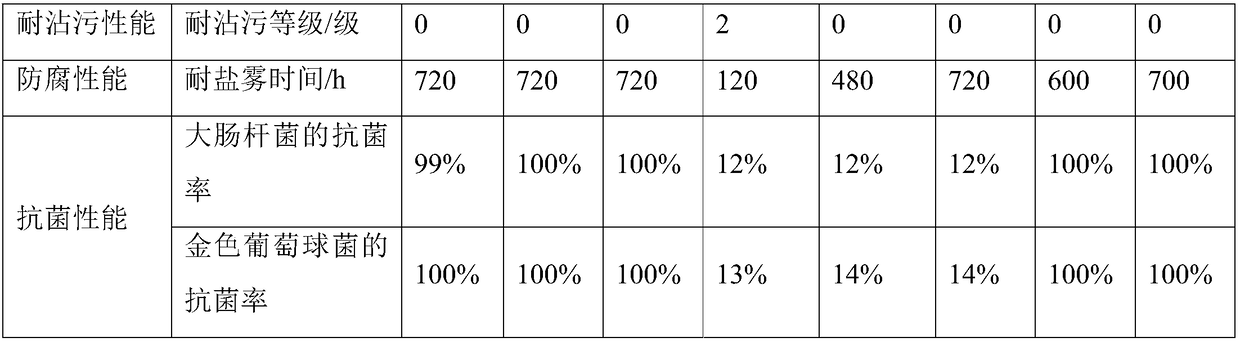

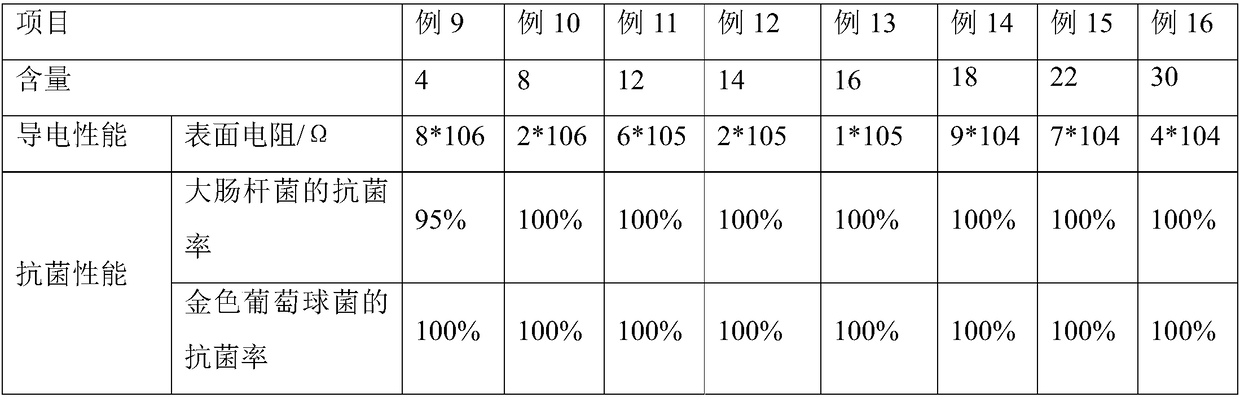

Examples

Embodiment 1

[0035] The dopant is ionic liquid 1-(propyl-3-sulfonic acid group) imidazolium dodecylbenzenesulfonate, and the specific preparation method is as follows:

[0036] (1) After mixing 1,3-propane sultone and ethyl acetate to form a solution with a mass fraction of 30%, add imidazole equimolar to 1,3-propane sultone, and stir at 500r / min After heating to 50°C, react for 24 hours, and centrifuge and wash to obtain the intermediate;

[0037] (2) After the intermediate in the step (1) is mixed with water to be prepared as an aqueous solution with a mass fraction of 40%, add and 1,3-propane sultone equimolar dodecylbenzenesulfonic acid, at 500r / Stirring and heating to 60°C for 48 hours under the condition of stirring for 48 hours, centrifuging and washing to obtain the dopant, which is set aside.

[0038] The functional filler is a carbon nanotube / polyaniline / silver ternary composite material, and the specific preparation method is as follows:

[0039] (1) mixing the dopant with deio...

Embodiment 2

[0050] The dopant is ionic liquid 1-(propyl-3-sulfonic acid group) imidazolium dodecylbenzenesulfonate, and the specific preparation method is as follows:

[0051] (1) After mixing 1,3-propane sultone and ethyl acetate to prepare a solution with a mass fraction of 50%, add imidazole equimolar to 1,3-propane sultone, and stir at 800r / min After heating to 80°C, react for 24 hours, and centrifuge and wash to obtain the intermediate;

[0052] (2) After the intermediate in the step (1) is mixed with water to be prepared as an aqueous solution with a mass fraction of 60%, add dodecylbenzenesulfonic acid with 1,3-propane sultone equimolar, at 1000r / Under the condition of stirring and heating for 1 min, the temperature was raised to 80°C, reacted for 48 h, and centrifuged and washed to obtain the dopant, which was set aside.

[0053] The functional filler is a carbon nanotube / polyaniline / silver ternary composite material, and the specific preparation method is as follows:

[0054] ...

Embodiment 3

[0065] The dopant is ionic liquid 1-(propyl-3-sulfonic acid group) imidazolium dodecylbenzenesulfonate, and the specific preparation method is as follows:

[0066] (1) After mixing 1,3-propane sultone and ethyl acetate to prepare a solution with a mass fraction of 50%, add imidazole equimolar to 1,3-propane sultone, and stir at 800r / min After heating to 80°C, react for 18 hours, and centrifuge and wash to obtain the intermediate;

[0067] (2) After the intermediate in the step (1) is mixed with water to be prepared as an aqueous solution with a mass fraction of 60%, add dodecylbenzenesulfonic acid with 1,3-propane sultone equimolar, at 1000r / Under the condition of stirring and heating for 1 min, the temperature was raised to 80°C, and then reacted for 12 hours, and centrifuged and washed to obtain the dopant, which was set aside.

[0068] The functional filler is a carbon nanotube / polyaniline / silver ternary composite material, and the specific preparation method is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com