Preparation method of strontium doping hydroxyapatite composite film

A technology of hydroxyapatite and composite film, which is applied in prosthesis, tissue regeneration, medical science, etc., can solve the problems of poor biological activity of bone materials, achieve good biological activity, stimulate osteoblast differentiation, and inhibit reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

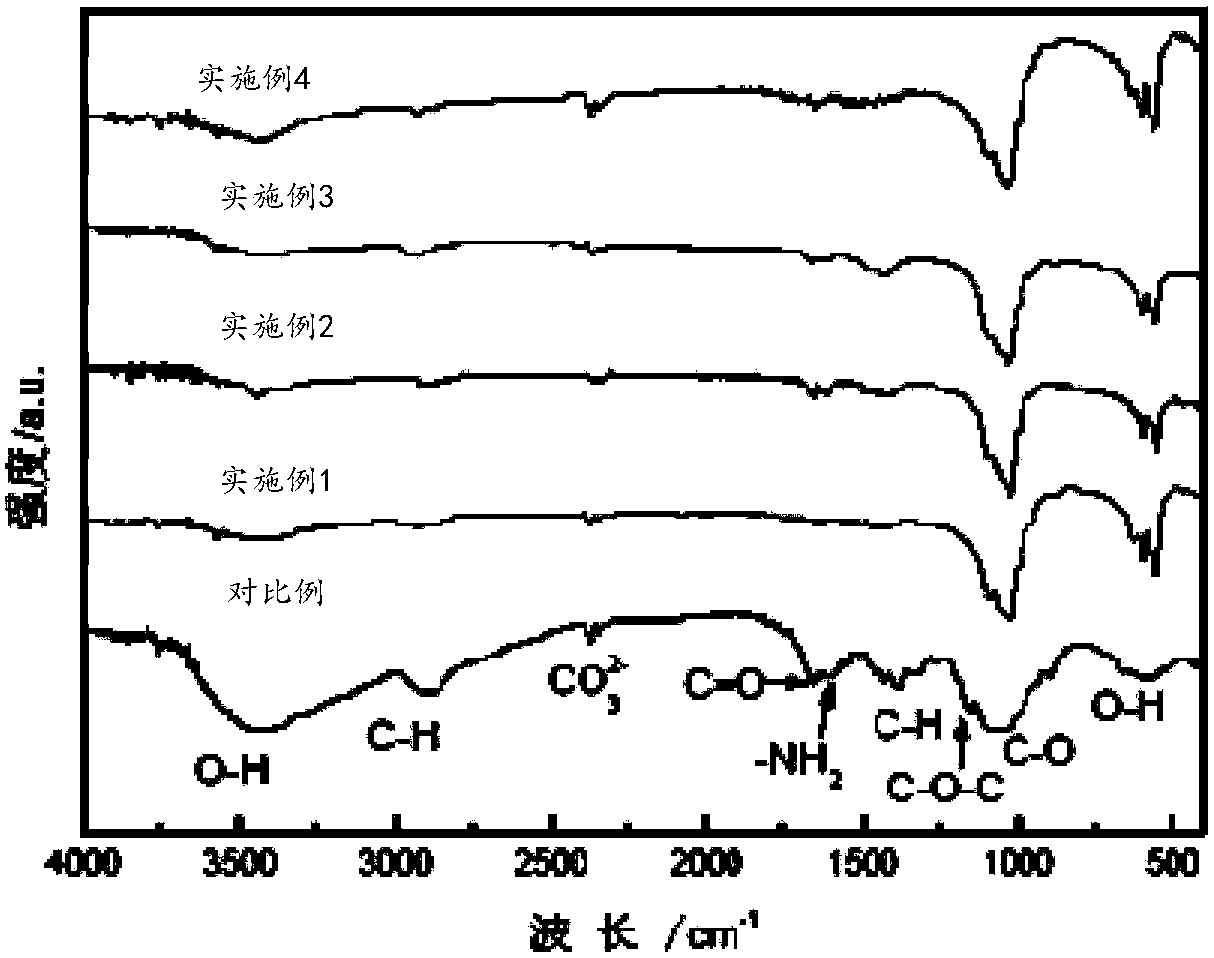

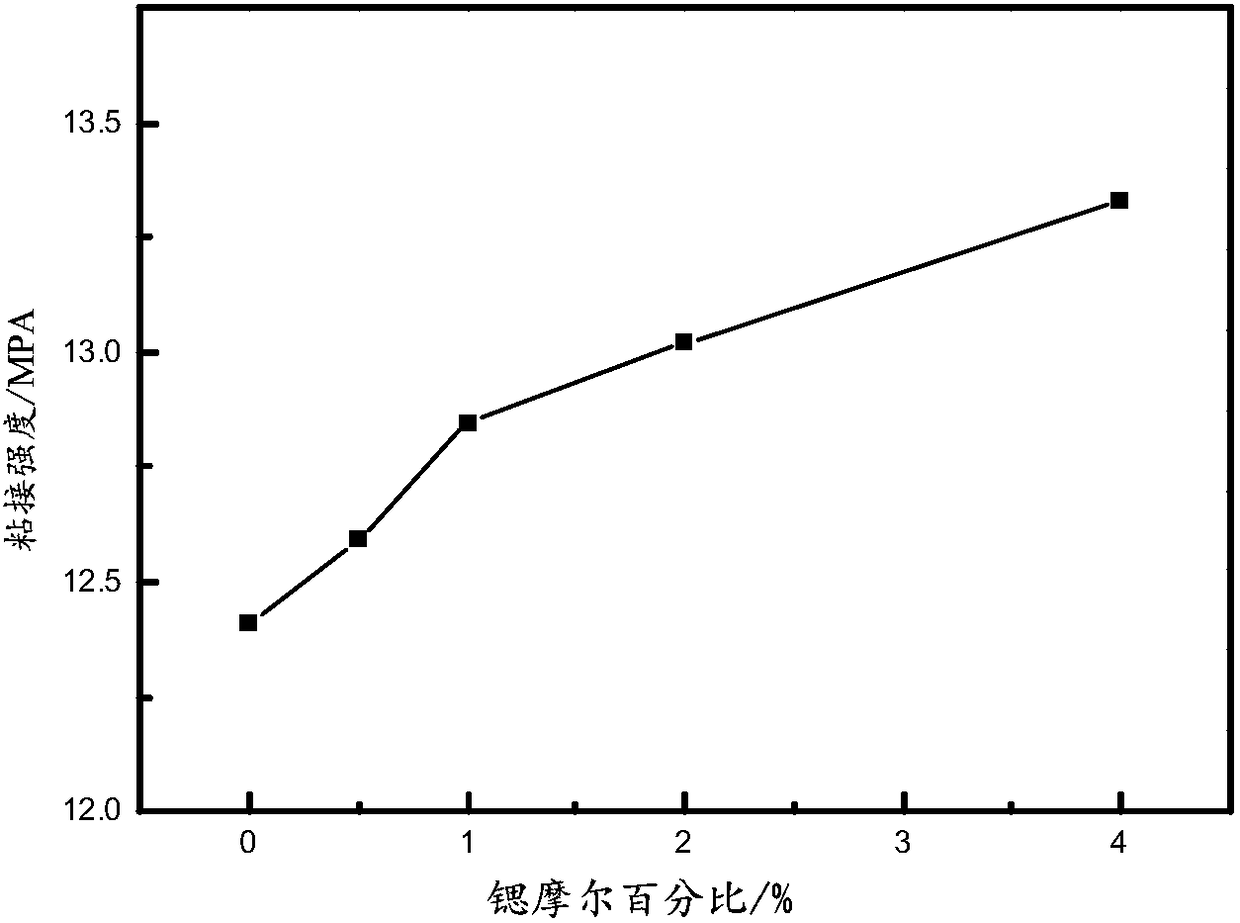

[0015] The preparation method of the strontium-doped hydroxyapatite composite film provided by the invention mainly includes the following steps:

[0016] Step 1. Mix the strontium salt solution with the calcium salt solution according to the molar ratio of [Sr] / [Sr+Ca] of 0.1~5:100, and according to the molar ratio of P / [Sr+Ca] of 1:1~2 Add the phosphate solution until a precipitate is formed, let stand and age for at least 12 hours, filter with suction, take the filter cake to dry, and place it at 600-1000°C for 2-5 hours to calcinate to obtain strontium-doped hydroxyapatite powder;

[0017] Step 2, mixing chitosan with acetic acid solution, adding strontium-doped hydroxyapatite powder into the chitosan mixture, and stirring to obtain a hydroxyapatite / chitosan suspension;

[0018] Wherein, the mass ratio of chitosan to hydroxyapatite powder is 1-3:3.

[0019] Step 3: Spin-coat the hydroxyapatite / chitosan suspension on the metal substrate and dry to obtain a strontium-doped ...

Embodiment 1

[0037] 1. Substrate pretreatment

[0038] A titanium metal substrate with a size of 10mm×10mm×1mm was polished on any side with 800#, 2000# and 5000# SiC water sandpaper in sequence, and then ultrasonically cleaned with acetone, absolute ethanol and deionized water for 15 minutes each, and then placed in the Dry at 50°C for 2.5 hours.

[0039] 2. Preparation of hydroxyapatite powder

[0040] Mix strontium nitrate solution and calcium nitrate solution according to the molar ratio of [Sr] / [Sr+Ca] at 0.5:100, and titrate and mix with disodium hydrogen phosphate solution according to the molar ratio of P / [Sr+Ca] at 1:1.67 Liquid, utilize sodium hydroxide solution to adjust the pH of the system to be 10.5-11 in the reaction process. Precipitate for 24 hours, filter with suction, take the filter cake, dry it at 60°C for 2 hours, and place it at 700°C for 3 hours to calcinate to obtain strontium-doped hydroxyapatite powder.

[0041] 3. Preparation of hydroxyapatite / chitosan suspen...

Embodiment 2

[0046] 1. Substrate pretreatment

[0047] A titanium metal substrate with a size of 10mm×10mm×1mm was polished on any side with 800#, 2000# and 5000# SiC water sandpaper in sequence, and then ultrasonically cleaned with acetone, absolute ethanol and deionized water for 15 minutes each, and then placed in the Dry at 50°C for 2.5 hours.

[0048] 2. Preparation of hydroxyapatite powder

[0049] Mix strontium nitrate solution and calcium nitrate solution according to the molar ratio of [Sr] / [Sr+Ca] of 1:100, and titrate and mix with disodium hydrogen phosphate solution according to the molar ratio of P / [Sr+Ca] of 1:1.67 Liquid, utilize sodium hydroxide solution to adjust the pH of the system to be 10.5-11 in the reaction process. Precipitate for 24 hours, filter with suction, take the filter cake, dry it at 60°C for 2 hours, and place it at 700°C for 3 hours to calcinate to obtain strontium-doped hydroxyapatite powder.

[0050] 3. Preparation of hydroxyapatite / chitosan suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com