Supported transition metal phosphide, preparation method thereof, and application thereof in catalytic hydrogen production

A transition metal, phosphide technology, used in phosphide, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of dangerous or expensive, polluting by-products, complicated and tedious steps, etc. The effect of few reaction steps, short reaction period and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

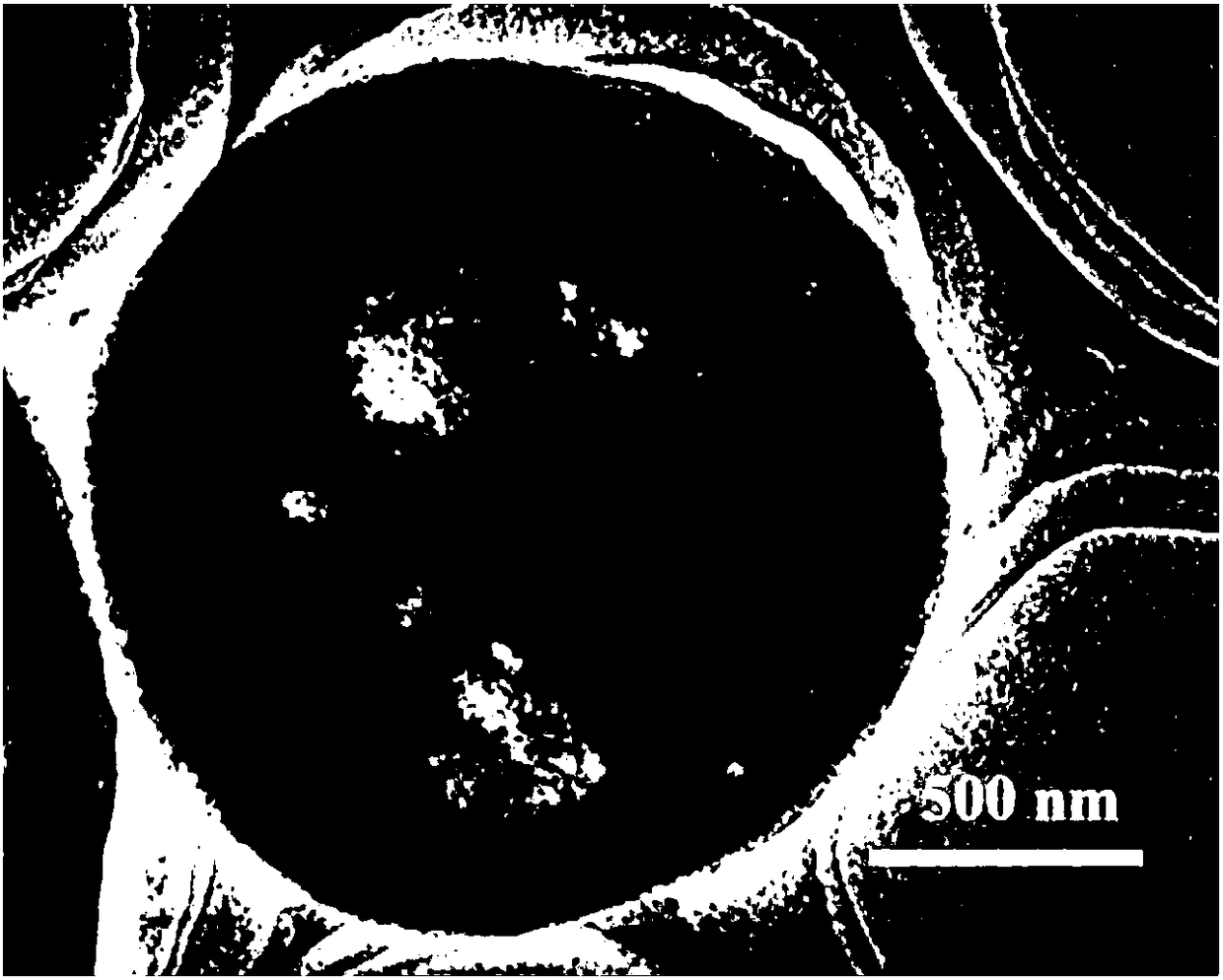

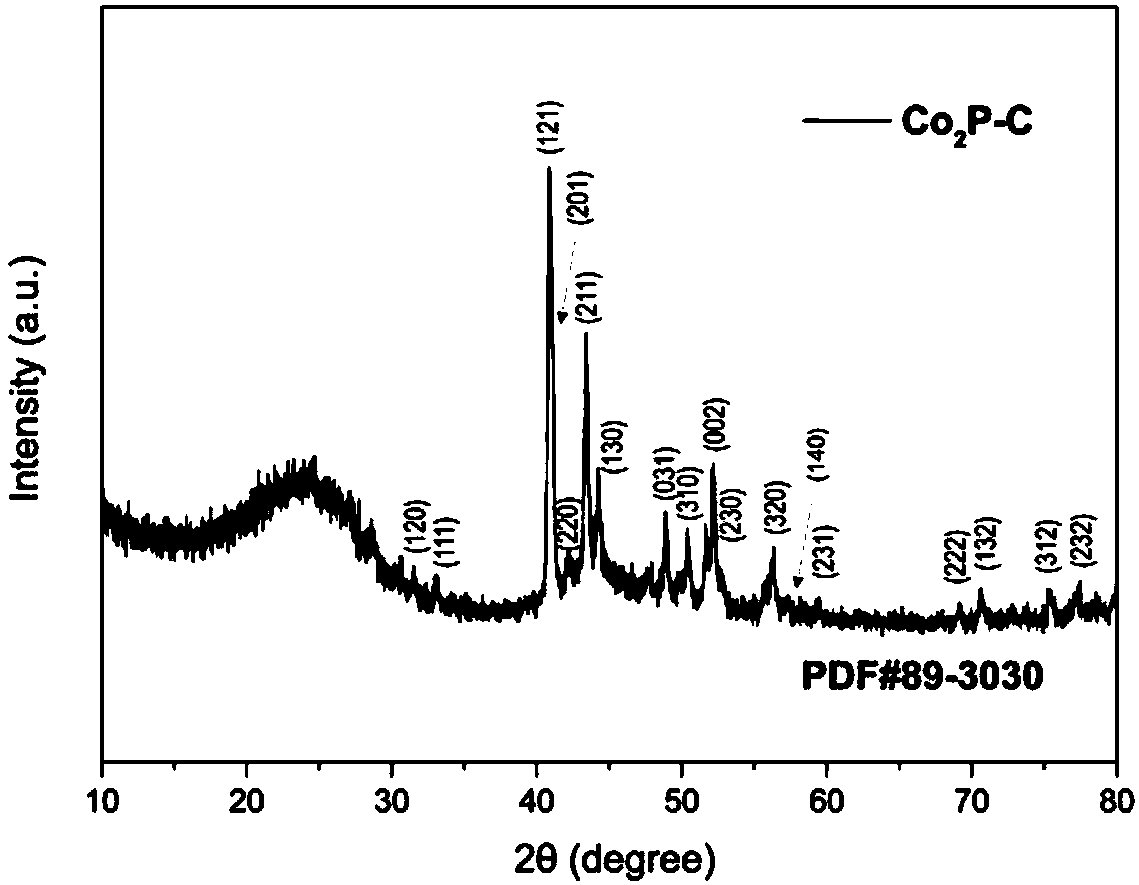

[0045] 1. Preparation of supported transition metal dicobalt phosphide (yeast as carbon source and phosphorus source)

[0046] Wash 1g of biomass material yeast with deionized water, disperse it in 30mL of deionized water, add 0.75g of sodium chloride, 50μL of glutaraldehyde and 0.1g of transition metal cobalt salt precursor cobalt acetate, and put it into a 100mL beaker Stir well. The above mixed solution was transferred into a polytetrafluoroethylene-lined autoclave for hydrothermal reaction at 190° C. for 8 h. After the reaction, it was collected by centrifugation, washed with water for 3 times, and washed with ethanol for 3 times. The collected precipitate was put into an oven and dried at 80°C for 8 hours to prepare the intermediate product a; after it was cooled to room temperature, it was placed in a tube In the furnace, the temperature was raised to 700° C. at a heating rate of 5° C. / min under an inert atmosphere, and kept for 6 hours to obtain a supported transition ...

Embodiment 2

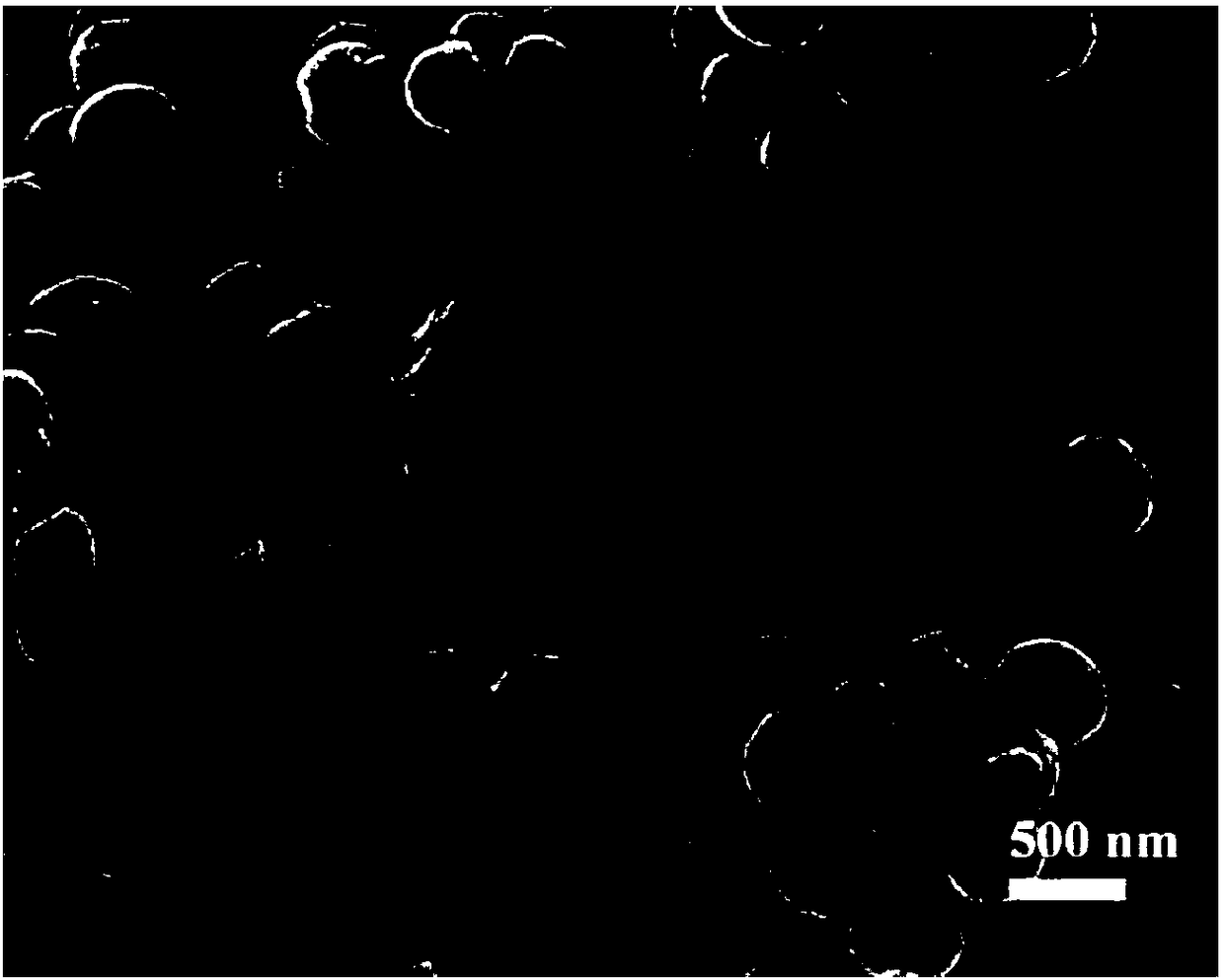

[0058] 1. Preparation of supported transition metal dicobalt phosphide (fungus fungus as carbon source and phosphorus source)

[0059] Soak 1g of biomass material fungus, wash it with deionized water, disperse it in 30mL of deionized water, add 0.75g of sodium chloride, 50μL of glutaraldehyde and 0.1g of transition metal cobalt salt precursor cobalt acetate, and put it into a 100mL beaker Mix well. The above mixed solution was transferred into a polytetrafluoroethylene-lined autoclave for hydrothermal reaction at 190° C. for 8 h. After the reaction, it was collected by centrifugation, washed with water for 3 times, and washed with ethanol for 3 times. The collected precipitate was put into an oven and dried at 80°C for 8 hours to prepare the intermediate product a; after it was cooled to room temperature, it was placed in a tube In the furnace, the temperature was raised to 700° C. at a heating rate of 5° C. / min under an inert atmosphere, and kept for 6 hours to obtain a supp...

Embodiment 3

[0068] 1. Preparation of supported transition metal dicobalt phosphide (Mushroom as carbon source and phosphorus source)

[0069] Wash 1g of the biomass material Tricholoma tricholoma with deionized water, put it into 30mL of deionized water, add 0.75g of sodium chloride, 50μL of glutaraldehyde and 0.1g of transition metal cobalt salt precursor cobalt acetate, put it into a 100mL beaker and stir uniform. The above mixed solution was transferred into a polytetrafluoroethylene-lined autoclave for hydrothermal reaction at 190° C. for 8 h. After the reaction, it was collected by centrifugation, washed with water for 3 times, and washed with ethanol for 3 times. The collected precipitate was put into an oven and dried at 80°C for 8 hours to prepare the intermediate product a; after it was cooled to room temperature, it was placed in a tube In the furnace, the temperature was raised to 900° C. at a heating rate of 5° C. / min under an inert atmosphere, and kept for 6 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com