Si-based gallium oxide film back gate solar-blind ultraviolet ray transistor and preparation method thereof

A gallium oxide and back gate technology is applied in the field of solar-blind ultraviolet phototransistors of Si-based gallium oxide thin film back gate and their preparation, which can solve the problems of limited application scope, difficult device integration process, etc. The process is simple and the effect of avoiding the interference of noise signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the Si-based gallium oxide film back gate solar-blind ultraviolet phototransistor comprises the following steps:

[0034] The first step, substrate pretreatment;

[0035] First take a piece of p-Si / SiO 2 (Si thickness is 0.5mm, resistivity is 5-10Ω·cm; SiO 2 Thickness is 300nm) as the substrate (purchased from Hefei Yuanjing Technology Materials Co., Ltd.), p-Si / SiO 2 Soak the substrate in acetone, ethanol, and deionized water in turn for 15 minutes, rinse with deionized water after taking it out, and finally dry it with dry argon, and set it aside;

[0036] The second step, in p-Si / SiO 2 Substrate SiO 2 A photosensitive layer is prepared on the layer.

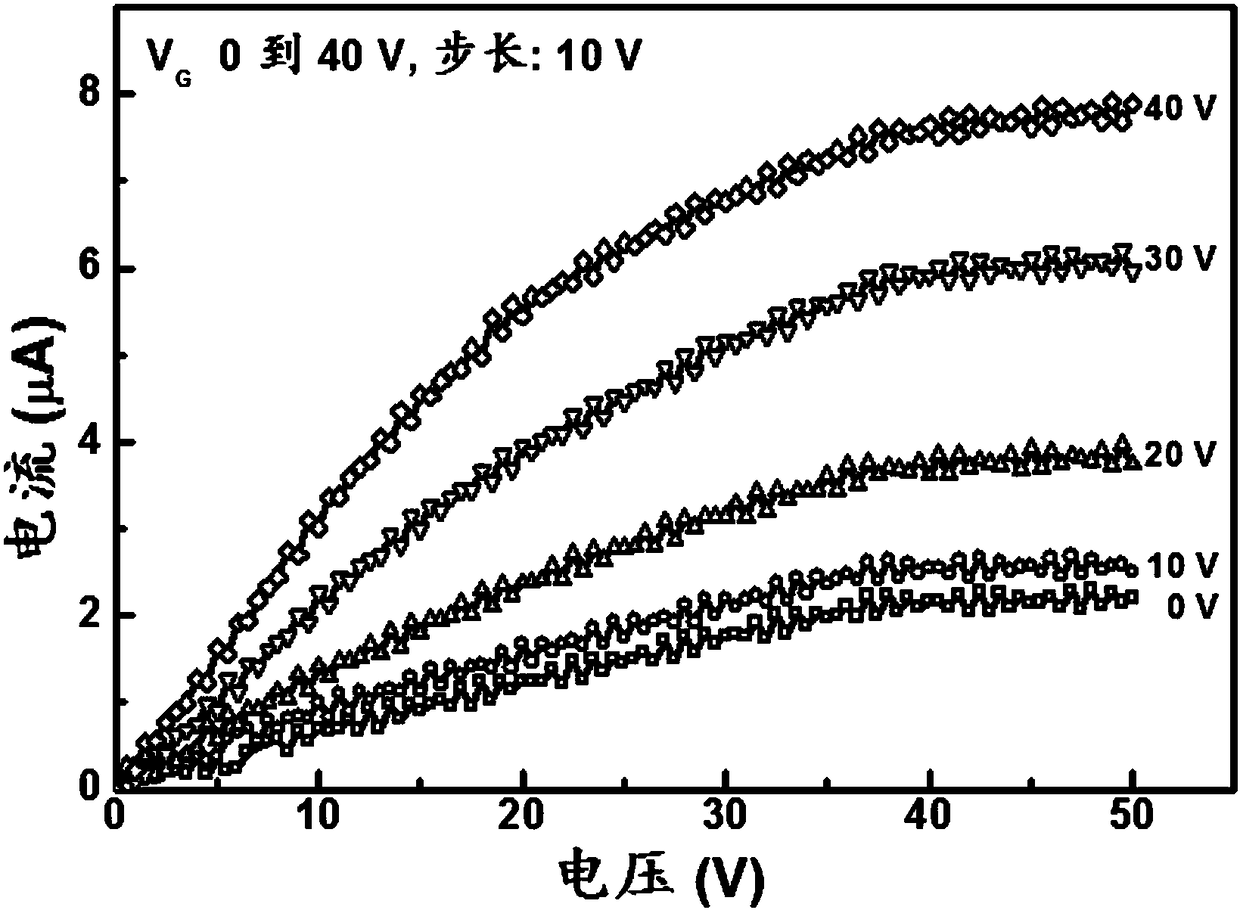

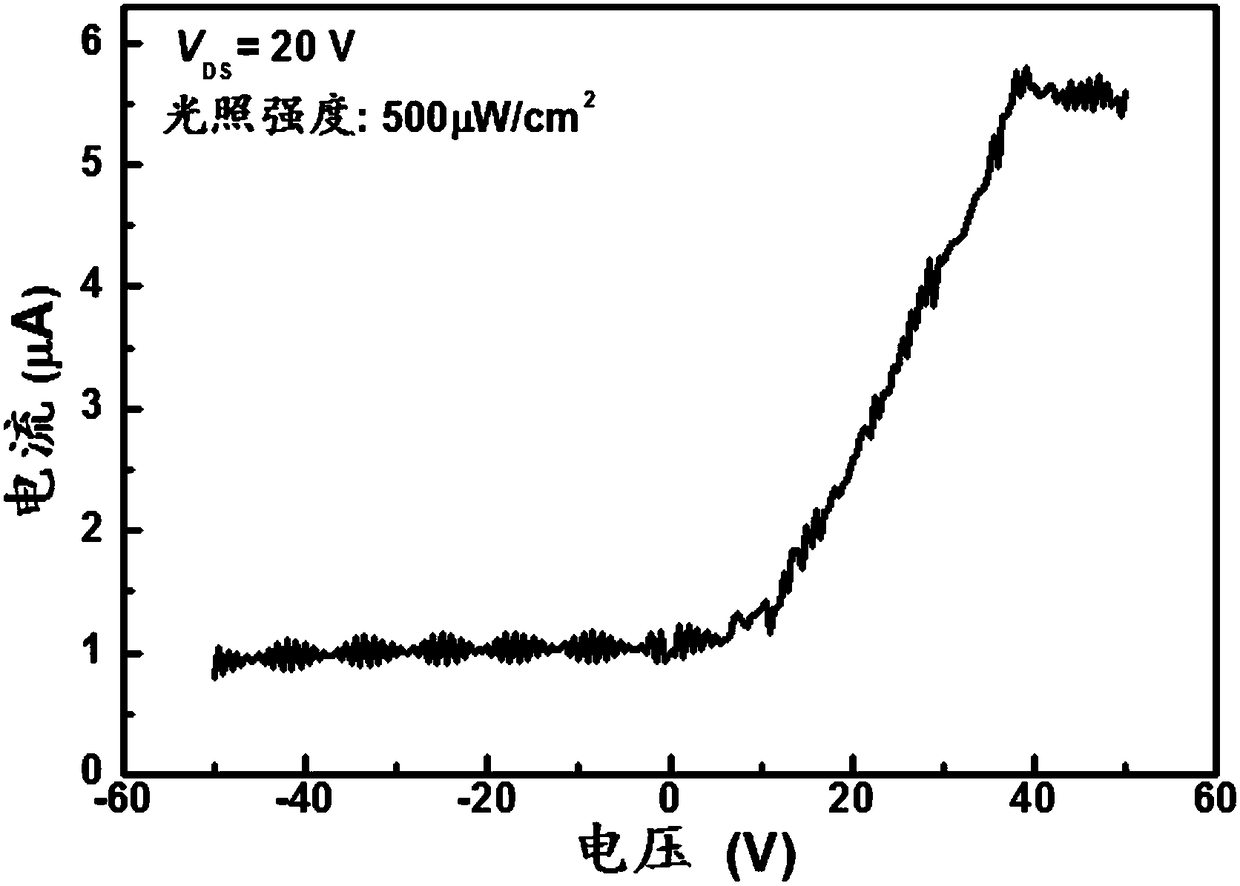

[0037] The above cleaned p-Si / SiO 2 substrate into the deposition chamber, the SiO 2 Growth of β-Ga on the side of the insulating gate layer 2 o 3 film. The adopted method includes magnetron sputtering, molecular beam epitaxy, pulse laser deposition or sol-gel method, and the thicknes...

Embodiment 1

[0043] First take a piece of p-Si / SiO with a size of 5mm×4mm 2 Substrate (Si thickness is 0.5mm, SiO 2 The thickness is 300nm) soaked in acetone, ethanol, and deionized water for 15 minutes respectively, rinsed with deionized water after taking it out, and finally dried with dry argon, and set aside.

[0044] The above cleaned p-Si / SiO 2 The substrate was placed in the deposition chamber, and the SiO 2 A layer of gallium oxide film of about 500nm is grown on the layer. The specific parameters of the magnetron sputtering method are as follows: the background vacuum is 1 × 10 -4 Pa, the working atmosphere is argon, the argon flow rate is 25 sccm, the working pressure is 0.8 Pa, the substrate temperature is 550°C, the sputtering power is 70W, and the sputtering time is 2h.

[0045] Cover the above-grown gallium oxide film with a hollow mask, and use the magnetron sputtering method to successively sputter a metal Ti electrode layer (about 6nm) and an Au electrode layer (about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com