Preparation method of corrosion-resisting type magnesium alloy surface ceramic membrane material

A magnesium alloy and ceramic membrane technology, applied in the field of ceramic membranes, can solve problems such as poor corrosion resistance, and achieve the effects of improving the electric field environment, improving corrosion resistance, and expanding the breakdown surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

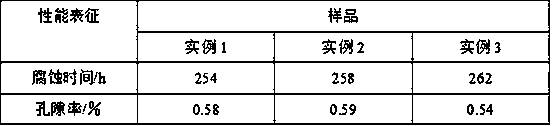

example 1

[0019] In terms of parts by weight, weigh 45 parts of 1% lysine solution by mass fraction, 0.1 parts of o-vanillin and 10 parts of absolute ethanol respectively in a Erlenmeyer flask, stir and mix them and place them in a water bath at 45°C for 2 hours, statically Cool to room temperature, filter and collect the filter cake, rinse with dimethyl sulfoxide for 3 times, then dry at 45°C for 3 hours, grind and pass through a 200-mesh sieve to obtain a sieved powder; in parts by weight, weigh Measure 45 parts of absolute ethanol, 10 parts of 1% zinc chloride solution by mass fraction and 1 part of sieved powder in a three-necked flask, then stir and mix with magnetic force at 75°C for 3 hours, then let it stand for 20 hours, filter and collect the filter residue, and use After rinsing the filter residue with absolute ethanol for 3 times, vacuum freeze-drying and grinding to obtain modified powder; in parts by weight, weigh 45 parts of deionized water, 6 parts of calcium acetate, 1 p...

example 2

[0021] In terms of parts by weight, weigh 47 parts of 1% lysine solution by mass fraction, 0.1 part of o-vanillin and 12 parts of absolute ethanol in a Erlenmeyer flask, stir and mix them and place them in a water bath at 47°C for 2 hours, statically Cool to room temperature, filter and collect the filter cake, rinse with dimethyl sulfoxide for 4 times, then dry at 47°C for 4 hours, grind and pass through a 200-mesh sieve to obtain a sieved powder; in parts by weight, weigh Measure 47 parts of absolute ethanol, 12 parts of 1% zinc chloride solution by mass fraction and 2 parts of sieved powder in a three-necked flask, and then stir and mix with magnetic force at 77°C for 4 hours, then let it stand for 22 hours, filter and collect the filter residue, and use After rinsing the filter residue with absolute ethanol for 4 times, vacuum freeze-drying and grinding and crushing, the modified powder was obtained; in parts by weight, 47 parts of deionized water, 7 parts of calcium acetat...

example 3

[0023] In terms of parts by weight, weigh 50 parts of 1% lysine solution by mass fraction, 0.2 parts of o-vanillin and 15 parts of absolute ethanol in a Erlenmeyer flask, stir and mix them and place them in a water bath at 50°C for 3 hours, statically Cool to room temperature, filter and collect the filter cake, rinse with dimethyl sulfoxide for 5 times, then dry at 50°C for 5 hours, grind and pass through a 200-mesh sieve to obtain a sieved powder; in parts by weight, weigh Measure 50 parts of absolute ethanol, 15 parts of 1% zinc chloride solution by mass fraction and 2 parts of sieved powder in a three-necked flask, and then stir and mix with magnetic force at 70°C for 5 hours, then let it stand for 24 hours, filter and collect the filter residue, and use After rinsing the filter residue with absolute ethanol for 5 times, vacuum freeze-drying and grinding and crushing, the modified powder was obtained; in parts by weight, 50 parts of deionized water, 8 parts of calcium aceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com