Carbon fiber reinforced polyester composite material and preparation method thereof

A technology of polyester composite material and carbon fiber is applied in the field of carbon fiber reinforced polyester composite material and its preparation. Enhanced interfacial and mechanical properties, improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

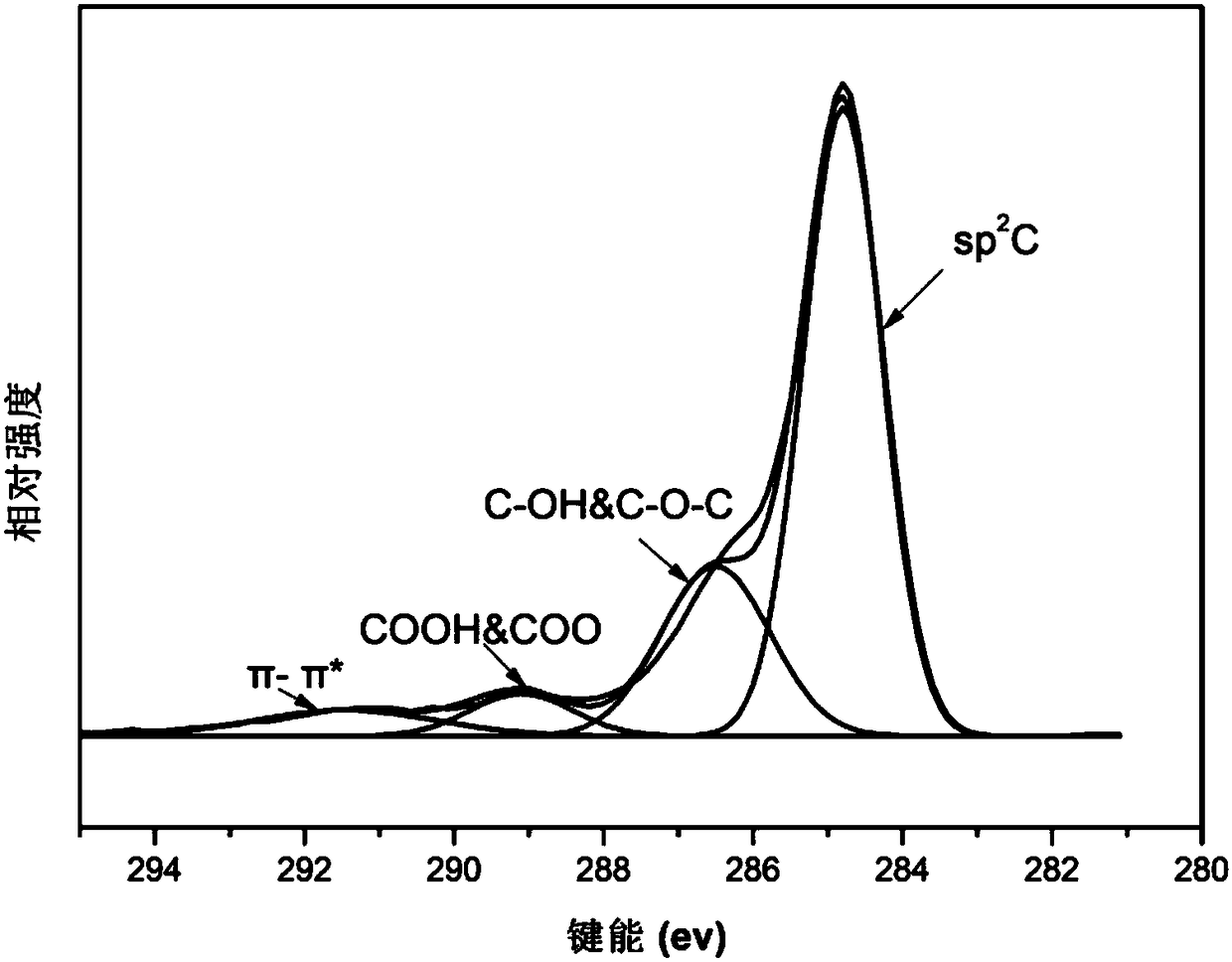

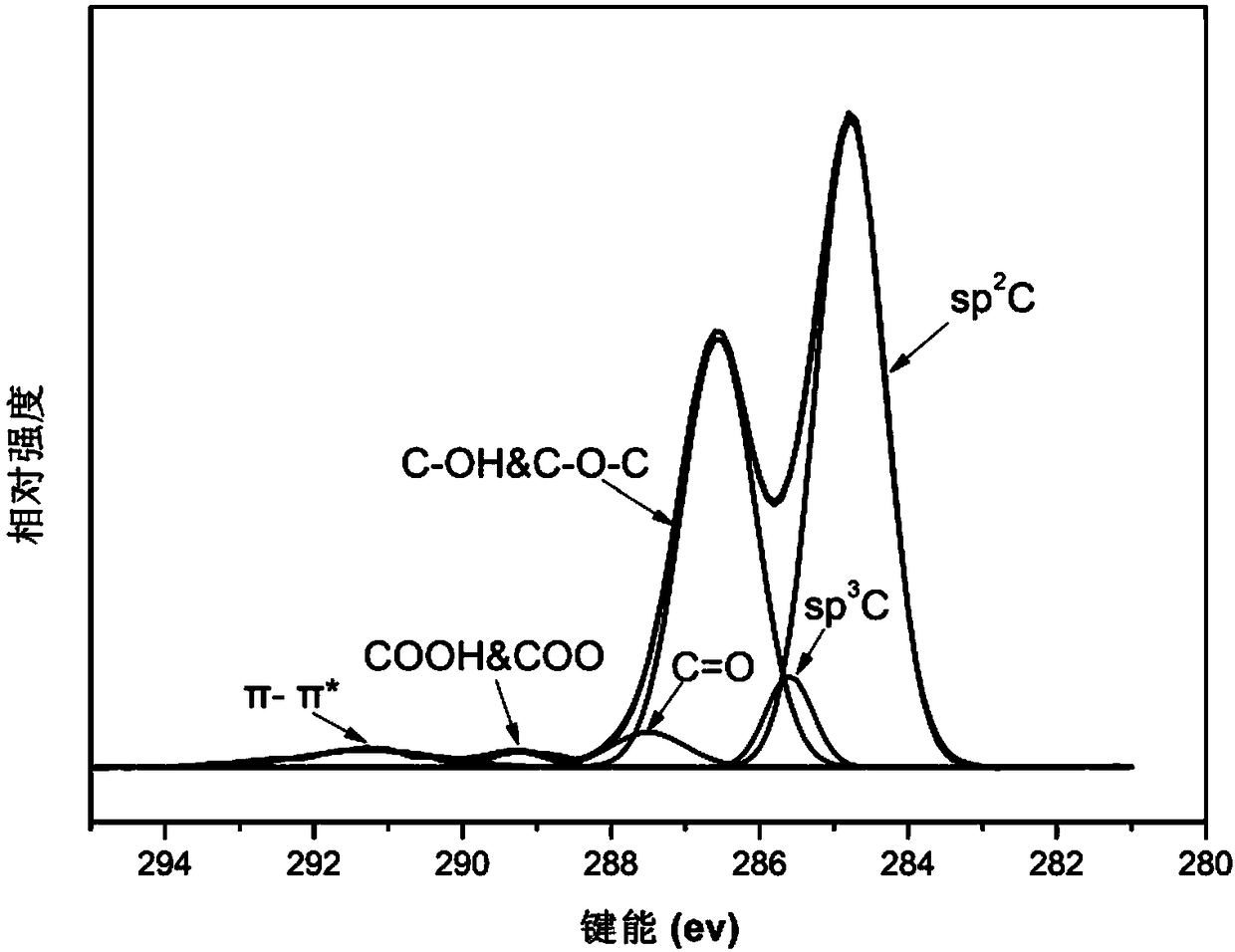

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of carbon fiber reinforced polyester composite material, the steps are as follows:

[0044] (1) Polyacrylonitrile-based carbon fiber and polybutylene terephthalate coated with epoxy resin sizing agent with an average length of 10μm are dried at 100°C for 2h, so that the water content is 0.019wt%;

[0045] (2) Polyacrylonitrile-based carbon fiber coated with epoxy resin sizing agent is kept at 280℃ for 10 minutes in an oxidizing atmosphere, and the oxidizing atmosphere is an air environment;

[0046] (3) The carbon fiber treated in step (1) is added through a twin-screw extruder with fiber opening, polybutylene terephthalate, tetra[β-(3,5-di-tert-butyl-4-hydroxybenzene) (Base) propionic acid] pentaerythritol ester and zinc stearate mixture is added from the hopper of a twin-screw extruder, and extruded to obtain a carbon fiber reinforced polyester composite material, wherein the surface is coated with polyacrylonitrile-based carbon fiber with epoxy resin si...

Embodiment 2

[0053] A preparation method of carbon fiber reinforced polyester composite material, the steps are as follows:

[0054] (1) Petroleum pitch-based carbon fiber and polyethylene terephthalate coated with a lactone-modified epoxy resin sizing agent with an average length of 3mm are dried at 150°C for 6h to make the water content 0.01wt% ;

[0055] (2) The petroleum pitch-based carbon fiber coated with lactone-modified epoxy resin sizing agent is kept for 0.5 min in an oxidizing atmosphere at 250°C, and the oxidizing atmosphere is a nitrogen dioxide environment;

[0056] (3) The carbon fiber treated in step (1) is added through a twin-screw extruder, and the polyethylene terephthalate, N,N'-bis-(3-(3,5-di-tert-butyl) The mixture of 4-hydroxyphenyl) propionyl) hexamethylene diamine and ethylene bis-fatty amide is added from the hopper of the twin-screw extruder, and extruded to obtain a carbon fiber reinforced polyester composite material, wherein the surface is coated with a lactone mod...

Embodiment 3

[0060] A preparation method of carbon fiber reinforced polyester composite material, the steps are as follows:

[0061] (1) Coal pitch-based carbon fiber and polybutylene terephthalate coated with a vinyl unsaturated polyester resin sizing agent with an average length of 100 μm were dried at 125°C for 4 hours to make the water content 0.015 wt%;

[0062] (2) The coal pitch-based carbon fiber coated with the vinyl unsaturated polyester resin sizing agent is kept for 15 minutes in an oxidizing atmosphere at 350°C, and the oxidizing atmosphere is a chlorine environment;

[0063] (3) Add the carbon fiber treated in step (1) through a twin-screw extruder and add fiber port, polybutylene terephthalate, tris[2,4-di-tert-butylphenyl] phosphite and ethylene -The mixture of acrylic copolymer is added from the hopper of the twin-screw extruder, and extruded to obtain a carbon fiber reinforced polyester composite material, in which the surface is coated with coal pitch-based carbon fiber and pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com