Activated rosin flux for series 400 ferritic stainless steel

A technology of active flux and ferrite, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of reduced corrosion resistance of materials, affecting the quality of seam welding, and limited application fields, so as to improve weldability, The effect of improving welding defects and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

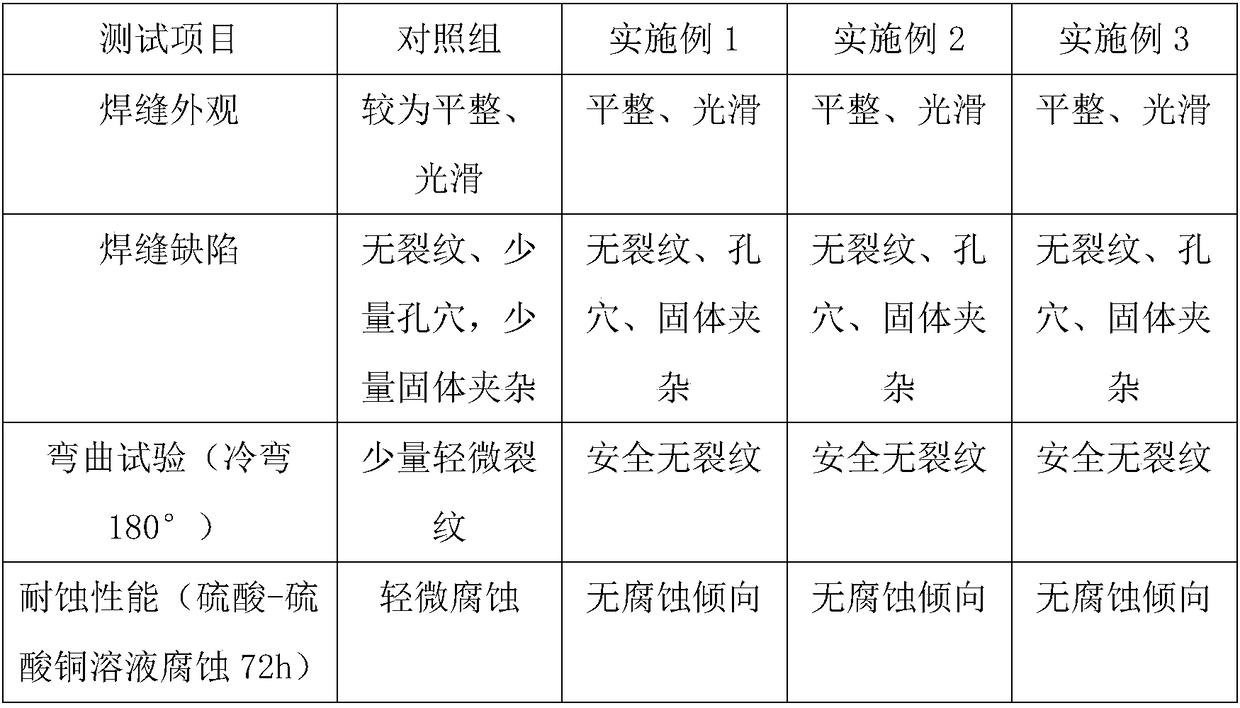

Examples

Embodiment 1

[0028] An active flux for 400 series ferritic stainless steel, according to mass percentage, the raw material components of the active flux include:

[0029] Calcium Fluoride 18.0%, Chromium Trioxide 12.5%, Aluminum Oxide 6.5%, Silicon Oxide 6.0%, Magnesium Oxide 2.6%, Titanium Dioxide 8.7%, Alloy Powder 2.5%, Titanium Aluminum Nitride 0.8%, Potassium Fluoborate 4.6%, Endothermic agent 12.5%, the balance is binder and unavoidable impurity.

[0030] Wherein, the endothermic agent is nanometer calcium carbonate.

[0031] The binder is potassium sodium water glass.

[0032] Sodium potassium water glass has a viscosity of 800-900Mpa·S at 20°C.

[0033] The mass fraction of P element in the impurity elements is lower than 0.05%; the mass fraction of S element is lower than 0.03%.

[0034] The alloy powder is a high-nickel manganese-copper alloy, and the content of nickel element in the alloy powder is 7.5%.

[0035] The active flux provided in this embodiment is used as a subme...

Embodiment 2

[0037] An active flux for 400 series ferritic stainless steel, according to mass percentage, the raw material components of the active flux include:

[0038] Calcium Fluoride 30.0%, Chromium Trioxide 16.4%, Aluminum Oxide 10.0%, Silicon Oxide 8.6%, Magnesium Oxide 4.9%, Titanium Dioxide 11.5%, Alloy Powder 3%, Titanium Aluminum Nitride 1.2%, Potassium Fluoborate 7.5%, Endothermic agent 14.5%, the balance is binder and unavoidable impurity.

[0039] Wherein, the endothermic agent is a mixture of nano calcium carbonate, bentonite and sodium bicarbonate, the content of sodium bicarbonate is 15%; the content of bentonite is 30%.

[0040] The binder is potassium sodium water glass.

[0041] Sodium potassium water glass has a viscosity of 800-900Mpa·S at 20°C.

[0042] The mass fraction of P element in the impurity elements is lower than 0.05%; the mass fraction of S element is lower than 0.03%.

[0043] The alloy powder is a high-nickel manganese-copper alloy, and the content of...

Embodiment 3

[0046] An active flux for 400 series ferritic stainless steel, according to mass percentage, the raw material components of the active flux include:

[0047] Calcium Fluoride 23.5%, Chromium Trioxide 14.9%, Aluminum Oxide 8.3%, Silicon Oxide 7.7%, Magnesium Oxide 3.9%, Titanium Dioxide 10.5%, Alloy Powder 2.8%, Titanium Aluminum Nitride 1.0%, Potassium Fluoborate 6.1%, Endothermic agent 13.9%, balance is binder and unavoidable impurity.

[0048] Wherein, the endothermic agent is a mixture of nano calcium carbonate, bentonite and sodium bicarbonate, the content of sodium bicarbonate is 10%; the content of bentonite is 20%.

[0049] The binder is potassium sodium water glass.

[0050] Sodium potassium water glass has a viscosity of 800-900Mpa·S at 20°C.

[0051] The mass fraction of P element in the impurity elements is lower than 0.05%; the mass fraction of S element is lower than 0.03%.

[0052] The alloy powder is a high-nickel manganese-copper alloy, and the content of nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com