A preparation process of transition metal carbide powder and transition metal carbide-nitride composite powder

A transition metal and composite powder technology, applied in the field of powder metallurgy, can solve the problems of coarse powder particles, high impurity content, and low output requirements of vapor deposition method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

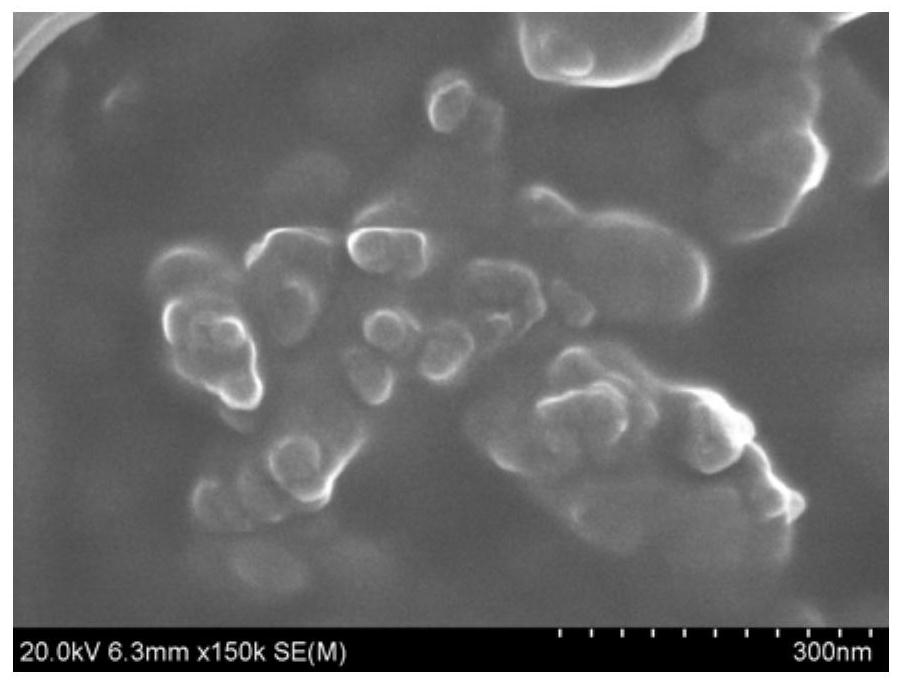

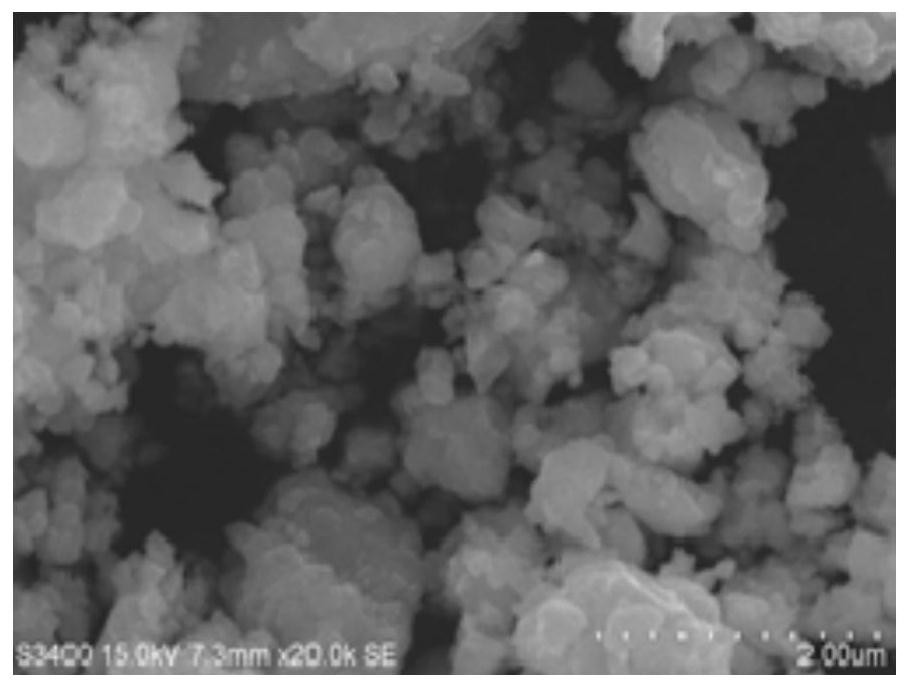

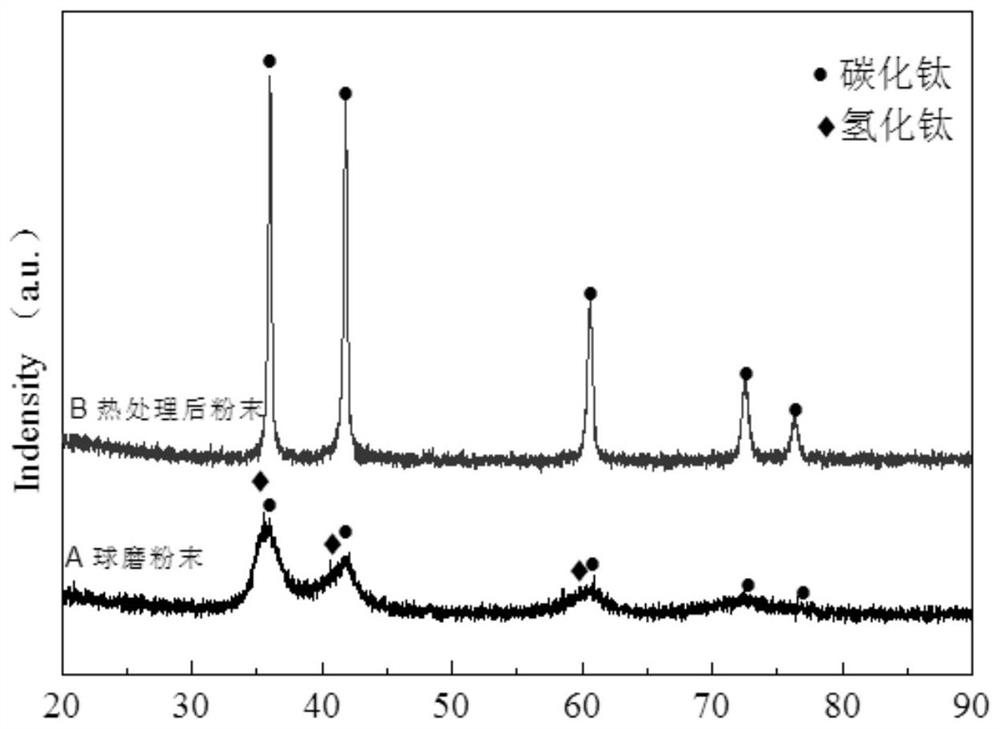

[0023] Glove box (1) in an argon environment protection, material selection 200 mesh titanium metal powder, the quality of 50g, purity 99.9%, the carbon-containing organic solvent is toluene, 18ml volume, carbide ball 500g, raw materials and ball into a stainless steel ball mill jar, after packaging in a ball mill rotating at 350 rev / min, the milling time was 30 hours, the nano powder after milling in vacuum (degree of vacuum figure 1 , image 3 Indicated.

[0024] (2) the resulting milled titanium carbide, titanium hydride composite powder was placed in a high temperature vacuum furnace (the degree of vacuum figure 2 Indicated. Titanium hydride decomposition after heat treatment, thermal processing, decomposition of the hydride to give the pure titanium metal, titanium metal, after reaction with the titanium carbide titanium carbide solid solution of a non-stoichiometric, such as image 3 , The carbon to titanium carbide powder was 7:10 molar ratio of titanium, oxygen content of ...

Embodiment 2

[0031] Glove box (1) in an argon environment protection, material selection 200 mesh titanium metal powder, the quality of 50g, purity 99.9%, containing carbon, the organic solvent is ethylene diamine N, a volume of 15ml, carbide ball 500g, raw materials and stainless steel ball mill pot was charged, after packaging in a ball mill, a rotational speed of 300 revolutions / minute 30 hours milling, milled powder was removed in vacuo (vacuum Figure 4 , Figure 5 Indicated.

[0032] (2) The ball-milled titanium carbide, titanium carbonitride, titanium hydride, titanium nitride in the composite powder is placed in a high temperature vacuum furnace (the degree of vacuum Figure 6 Shown), the carbon composite powder, the molar ratio of nitrogen to titanium of 6: 2: 10, an oxygen content of 0.40%. The preparation of ultrafine titanium carbide, titanium nitride powder and 10% mass fraction of 20% of molybdenum metal and nickel ball mill mixing, the mixed powder was placed in a graphite compos...

Embodiment 3

[0034] (1) Among the metal-resistant glove boxes, the raw materials were selected from 200 mesh metal titanium powder and metal zirconium powder, titanium and zirconium atomic ratio of 8: 2, with a total mass of 50 g, and the purity was 99.9%, including The carbon or organic solvent is toluene, the volume is 16mL, the carbonide mill is 500g, the raw material and the grinding ball are loaded into the stainless steel ball grinding, and the ball mill is loaded into the ball mill. After 20 hours of rotation of 300 rpm, the powder is removed from the powder. 2 hours were dried in vacuum (vacuum Figure 7 , Figure 8 Indicated.

[0035] (2) Titanium carbide, carbonized zirconium, hydrogenide, and hydrogenide, and hydrogenated, and hydrogenated, and the vacuum is set to 10 ° C / min, and the temperature is 900 ° C, the temperature is 5 min. . The prepared composite powder average grain size 300 nm (eg Figure 9 The standard PDF card, which compares titanium carbide and carbon zirconium, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com