Preparation method of a fluorinated halloysite nanotube/waterborne polyurethane composite hydrophobic coating

A technology of halloysite nanotubes and water-based polyurethane, which is applied in the field of preparation, can solve the problems of restricting the extensive research and application of carbon nanotubes, the complicated preparation process of carbon nanotubes, and the high requirements of the processing environment, and achieve unique surface characteristics, good Effects of biocompatibility and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a method for preparing a fluorinated halloysite nanotube / water-based polyurethane composite hydrophobic coating, comprising the following steps:

[0042] S1, modification of halloysite nanotubes,

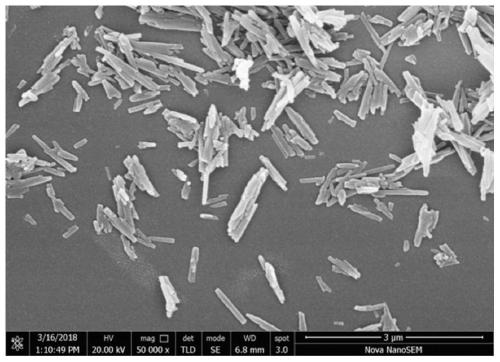

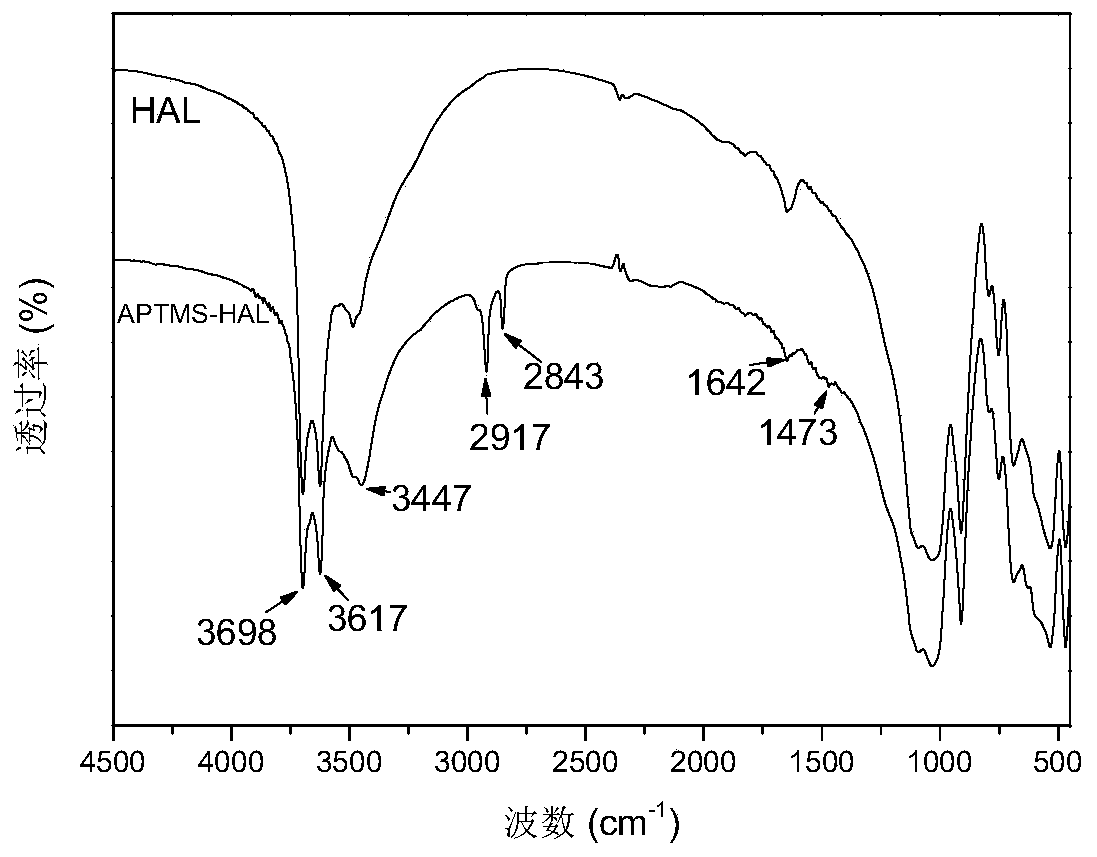

[0043] Weigh a certain mass of halloysite nanotubes and dissolve them in 75% ethanol aqueous solution, ultrasonically vibrate for 30-45min, add a certain mass of ammonia water and 3-aminopropyltrimethoxysilane, stir at room temperature for 24h-36h, then centrifuge and separate with The anhydrous ethanol and water are respectively washed 2-3 times, dried after centrifugal separation, and the modified halloysite nanotubes are obtained.

[0044] S2, preparation of halloysite nanotube / waterborne polyurethane composite emulsion,

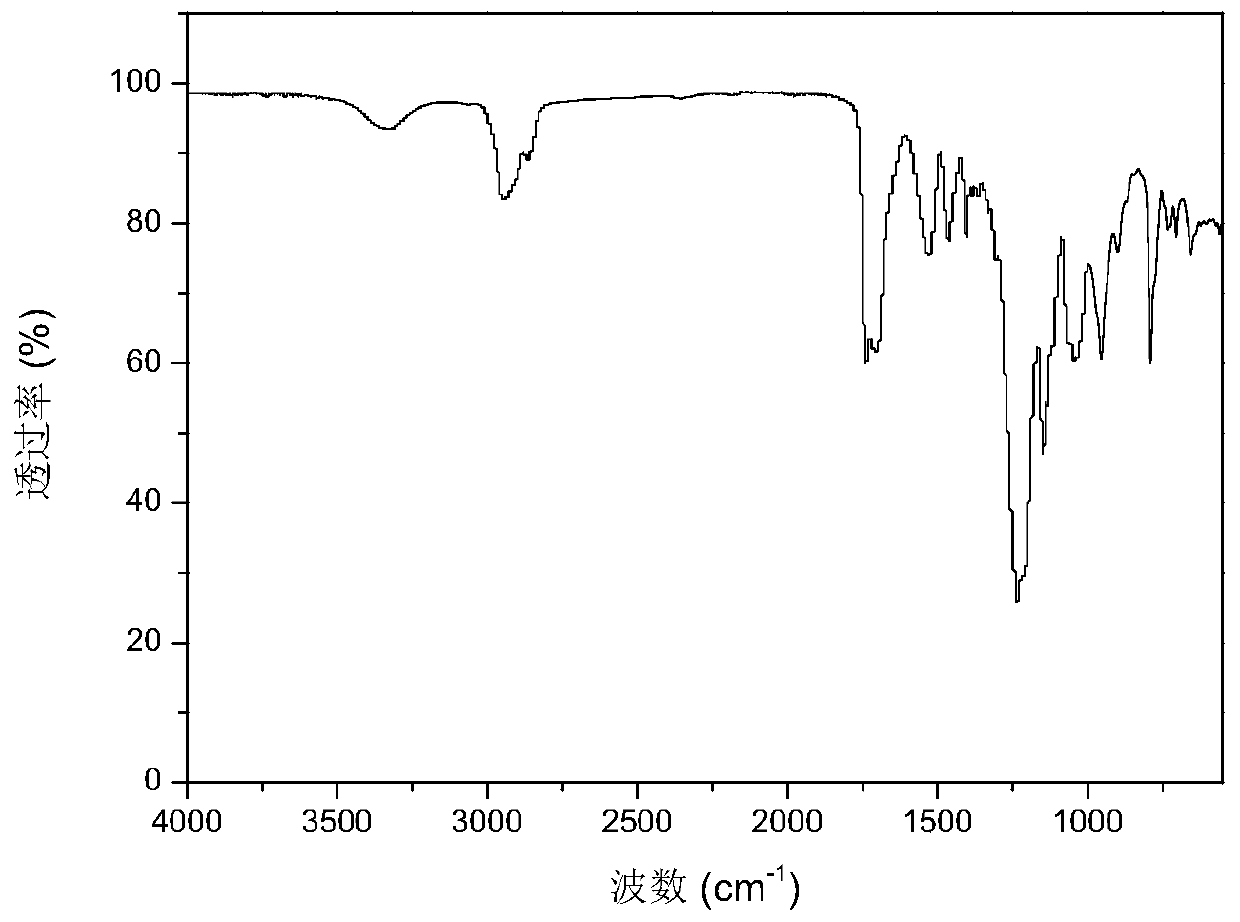

[0045] Mix the modified halloysite nanotubes, isocyanate and polyol, and react at 75°C-90°C until the NCO content reaches a stable state. Add a certain quality of 2,2-dimethylolbutyric acid, 1,4-butanediol, dibutyltin dilaurate a...

Embodiment 1

[0057] In a three-necked flask equipped with a condenser tube and a stirrer, add 12.8g of polycarbonate diol (PCDL2000) and 400mg of modified halloysite nanotubes, raise the temperature to 85°C, and wait until PCDL is completely dissolved and mixed with Angstrom After the stellite nanotubes were uniformly mixed, 5 g of isophorone diisocyanate was added into the flask, and the mixture was continuously stirred and reacted until the NCO content reached a stable value. Add 0.7g of 2,2-dimethylolbutyric acid (DMBA) hydrophilic chain extender, 0.54g of 1,4-butanediol small molecule chain extender and two drops of dibutyltin dilaurate catalyst, while adding Acetone, react until the NCO content reaches a stable value, then lower the reaction temperature to 50°C, add 0.47g triethylamine to neutralize for 30min, then add deionized water, stir and emulsify at 1200r / min for 1h, and distill off the acetone under reduced pressure , to obtain aqueous polyurethane composite emulsion. It is s...

Embodiment 2

[0060] The difference from Example 1 is that 400 mg of the modified halloysite nanotubes is changed to 300 mg, and other components and processes are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com