A kind of preparation method of all-solid polymer electrolyte and all-solid polymer battery

An all-solid polymer and electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc., can solve the problems of weakening ionic conductivity, reducing the mechanical strength and energy density of electrolytes, and easily changing the flexibility of molecular chains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the all-solid electrolyte of the present invention is as follows:

[0035] S1. Add 5-70 parts by mass of polycarbonate monomer and 0.5-6 parts by mass of carboxyl or hydroxyl polycarbonate monomer into the reactor for polymerization reaction, and obtain polymer A after purification;

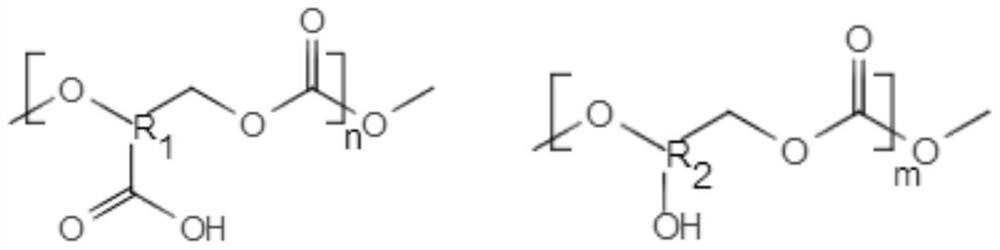

[0036]The polycarbonate monomer can be one or more of diphenolic propane and trimethylene carbonate, and the carboxyl or hydroxy polycarbonate monomer can be 2,2-bis(4-hydroxyphenyl)propionic acid, 5-Methyl-2-oxo-1,3-dioxane-5-carboxylic acid, 5-hydroxy-1,3-dioxan-2-one, 5-ethyl-5-(hydroxymethyl One or more of )-1,3-dioxan-2-one; polycarbonate monomers and polycarbonate monomers containing carboxyl or hydroxyl groups can be processed by phosgene method, transesterification method or thermal catalysis method Carry out the polymerization reaction, the obtained polymer A is a polycarbonate polymer containing carboxyl or carboxyl groups, and one of the polymers has a...

Embodiment 1

[0046] S1, add 5 parts by mass of trimethylene carbonate and 0.5 parts by mass of 5-methyl-2-oxo-1,3-dioxane-5-carboxylic acid into the reactor, and carry out a polymerization reaction by using a thermal catalytic polymerization method , continue to pass nitrogen into the reactor and continue to stir at a rotating speed of 200r / min, then add 30 parts by mass of toluene (solvent), 0.01 parts by mass of stannous isooctoate (catalyst), and react at 100 ° C for 60min to obtain polymer A ; The catalyst used in this step can also be tributyl tin oxide or tin acetate or rare earth or biological enzyme besides being stannous isooctanoate;

[0047] S2, add 80 parts by mass of polyethylene glycol methyl ether methacrylate (molecular weight 300) and 0.5 parts by mass of polyethylene glycol methyl methacrylate (molecular weight 2500) into 300 parts by mass of toluene, continue to pass nitrogen, at 500 r Stir at a rotating speed of / min, then add 30 parts by mass of lithium bistrifluoromet...

Embodiment 2

[0056] S1. Add 70 parts by mass of trimethylene carbonate and 6 parts by mass of 5-hydroxy-1,3-dioxan-2-one into the reactor to carry out thermal catalytic polymerization, and continue to pass nitrogen into the reactor and continue to use Stir at a rotational speed of 800 r / min, then add 60 parts by mass of toluene and 0.9 parts by mass of tributyltin oxide, and react at 100° C. for 80 min to obtain polymer A;

[0057] S2, adding 10 parts by mass of polyethylene glycol methyl ether methacrylate (molecular weight 20,000), 5 parts by mass of polyethylene glycol methyl methacrylate (molecular weight 300), and 10 parts by mass of polyethylene oxide (molecular weight 10 million) In 200 parts by mass of tetrahydrofuran, nitrogen was continuously passed through, stirring at a rotational speed of 800 r / min, then 5 parts by mass of lithium bis-oxalate borate (LiBOB), 0.05 part by mass of benzoyl tert-butyl peroxide, and 5 parts by mass of benzoyl tert-butyl peroxide were added and mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com