Boron and nitrogen codoped mesoporous carbon based catalyst as well as preparation method and application thereof

A mesoporous carbon and co-doping technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high price of diamond, limit the application of boron-doped diamond electrodes, etc., and achieve simple operation, low cost, and raw material conversion rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

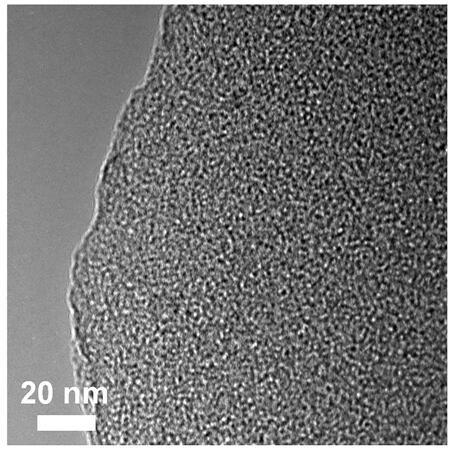

[0037] Preparation of catalysts based on boron and nitrogen co-doped mesoporous carbon:

[0038] (1) Dissolve 2.0g of block copolymer P123, 0.2g of boron oxide and 0.2g of melamine in 20g of methanol, add 10g of phenolic resin, add 15g of N-butylpyridine tetrafluoroborate, stir for 30min, at room temperature After volatilizing the methanol for 5 hours, the compound was cured in a normal pressure oven at 50°C for 12 hours, and then cured in a normal pressure oven at 100°C for 12 hours to obtain a cured product;

[0039](2) The cured product obtained in step (1) is ball milled. The method is: put the cured product into a ball mill tank, and add 6 small balls (2 with a diameter of 1.2cm, 2 with a diameter of 0.7cm, and 2 with a diameter of 0.5cm) , at a rotation speed of 50r / min and a revolution speed of 100r / min, grind for 0.5h to obtain a powdery product;

[0040] (3) Roasting the powdered product of step (2), the method is: under an ammonia atmosphere, put the powdered produc...

Embodiment 2

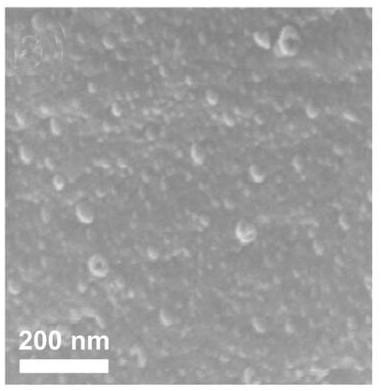

[0044] Preparation of catalysts based on boron and nitrogen co-doped mesoporous carbon:

[0045] (1) Dissolve 3.0g of block copolymer P103, 0.5g of boron nitride and 0.5g of dicyandiamide in 30g of ethanol, add 20g of polyester resin, add 10g of 1-pentyl-3-methylimidazole tetra Fluoroborate, stirred for 40 minutes, after volatilizing ethanol at room temperature for 7 hours, the compound was cured in a 70°C normal pressure oven for 14 hours, and then cured in a 120°C normal pressure oven for 14 hours to obtain a cured product;

[0046] (2) Ball mill the cured product of step (1), the method is: put the cured product into a ball mill tank, add 12 small balls (4 with a diameter of 1.2cm, 4 with a diameter of 0.7cm, and 4 with a diameter of 0.5cm ), grind for 1 hour at a rotation speed of 70r / min and a revolution speed of 140r / min to obtain a powdery product;

[0047] (4) (3) Roasting the powdered product of step (2), the method is: under a nitrogen atmosphere, the powdered produ...

Embodiment 3

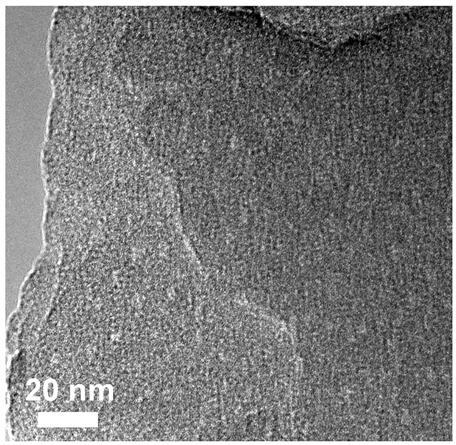

[0051] Preparation of catalysts based on boron and nitrogen co-doped mesoporous carbon:

[0052] (1) Dissolve 4.0g of block copolymer P85, 0.7g of boric acid and 0.7g of urea in 40g of isopropanol, add 30g of polyamide resin, add 20g of 1-hexyl-3-methylimidazolium tetrafluoroborate, and stir After 50 minutes, isopropanol was volatilized at room temperature for 9 hours, the compound was cured in a 90°C normal pressure oven for 16 hours, and then cured in a 130°C normal pressure oven for 16 hours to obtain a cured product;

[0053] (2) Ball mill the cured product of step (1), the method is: put the cured product into a ball mill tank, add 18 small balls (6 with a diameter of 1.2cm, 6 with a diameter of 0.7cm, and 6 with a diameter of 0.5cm ), grinding for 1.5h at a rotation speed of 100r / min and a revolution speed of 200r / min to obtain a powdery product;

[0054] (3) Roasting the powdered product of step (2), the method is: under an argon atmosphere, the powdered product is pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com