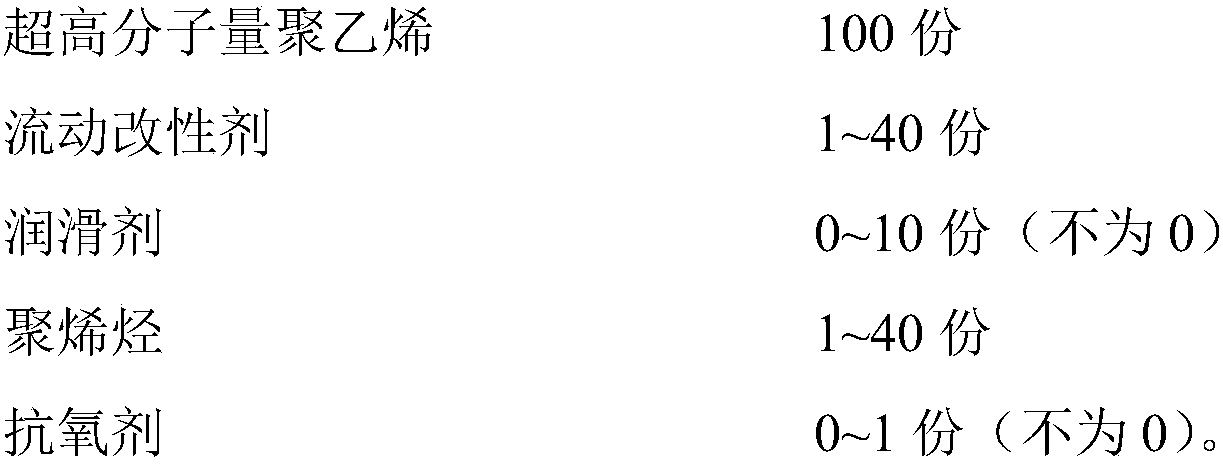

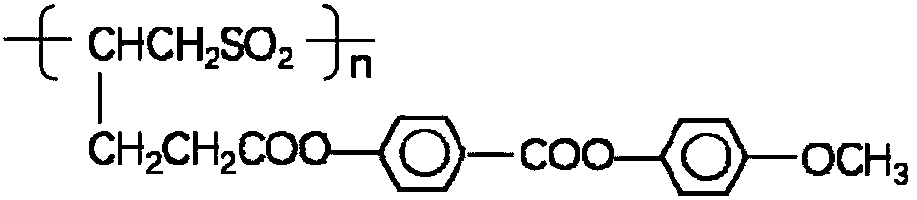

Composite material for preparing intermediate strength fibers and quick forming method and application hereof

A composite material and medium-strength fiber technology, applied in the direction of fiber chemical characteristics, conjugated synthetic polymer rayon, rayon manufacturing, etc., can solve the problem of low critical shear rate, thermal shear insensitivity, high melt viscosity, etc. problems, to achieve the effects of simple equipment and process, reduced production and preparation costs, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Put 10 parts of polycarbonate thermotropic liquid crystal polymers (with a melting point of 138°C) and 100 parts of polyethylene grafted with maleic anhydride in a mixing tank and mix them uniformly to prepare a flow modifier. The structural formula of the polycarbonate thermotropic liquid crystal polymer is:

[0031]

[0032] (2) 100 parts of ultra-high molecular weight polyethylene (molecular weight distribution is 4.8, viscosity-average molecular weight is 1.02 million) and 1 part of flow modifier prepared in step (1) are mixed uniformly to prepare component A; 0.1 part Polyethylene wax, 1 part of low-density polyethylene (melt index 27g / 10min) was mixed uniformly in a mixing tank to obtain component B; component A was uniformly mixed with component B and 0.1 part of antioxidant 1010 to obtain a composite special material.

[0033] (3) Extrude the prepared medium-strength fiber composite special material through a single-screw extruder with an aspect ratio of...

Embodiment 2

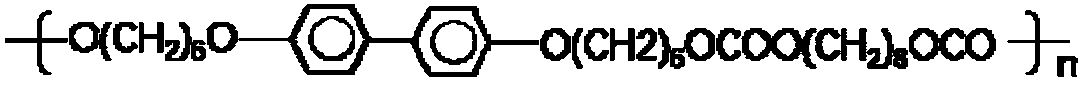

[0035] (1) 100 parts of polyamide thermotropic liquid crystal polymer (copolyester of hydroxybenzoic acid, hydroquinone, sebacic acid) (melting point is 239 ° C), 100 parts of polyethylene with methacrylic acid Place in a mixing kettle and mix evenly to obtain a flow modifier.

[0036] (2) 100 parts of ultra-high molecular weight polyethylene (molecular weight distribution is 4.2, viscosity-average molecular weight is 5.96 million) and 40 parts of flow modifiers prepared in step (1) are mixed to obtain component A; 10 parts A mixture of polyethylene wax and oleic acid amide, 40 parts of high-density polyethylene (melt index 18g / 10min) is mixed uniformly in a mixing tank to prepare component B; component A and component B and 1 part of antioxidant 1076 Mix evenly to prepare composite special material.

[0037] (3) Extrude the prepared medium-strength fiber composite special material through a single-screw extruder with an aspect ratio of 30 and a compression ratio of 5 through...

Embodiment 3

[0039] (1) 50 parts of polyamide thermotropic liquid crystal polymer (copolyester of hydroxybenzoic acid, hydroquinone, sebacic acid) (melting point is 239 ° C), 100 parts were contacted with methyl methacrylate The branched polyethylene is placed in a mixing kettle and mixed evenly to obtain a flow modifier.

[0040] (2) 100 parts of ultra-high molecular weight polyethylene (molecular weight distribution is 4.3, viscosity average molecular weight is 2,500,000) and 20 parts of flow modifiers prepared in step (1) are mixed to obtain component A; 5 parts The mixture of calcium stearate and magnesium stearate, 20 parts of high-density polyethylene (melt index 18g / 10min) are mixed homogeneously in the mixing tank to prepare component B; component A and component B and 0.5 part of antioxidant Agent 264 is mixed evenly to prepare composite special material.

[0041] (3) Extrude the prepared medium-strength fiber composite special material through a single-screw extruder with a leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com