A preparation method of bean dregs-based nitrogen-boron co-doped porous carbon material

A porous carbon material, bean dregs-based nitrogen-boron technology, applied in the field of material science, can solve the problems of high price and complex preparation process, and achieve the effect of simple method, various types, and compact internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

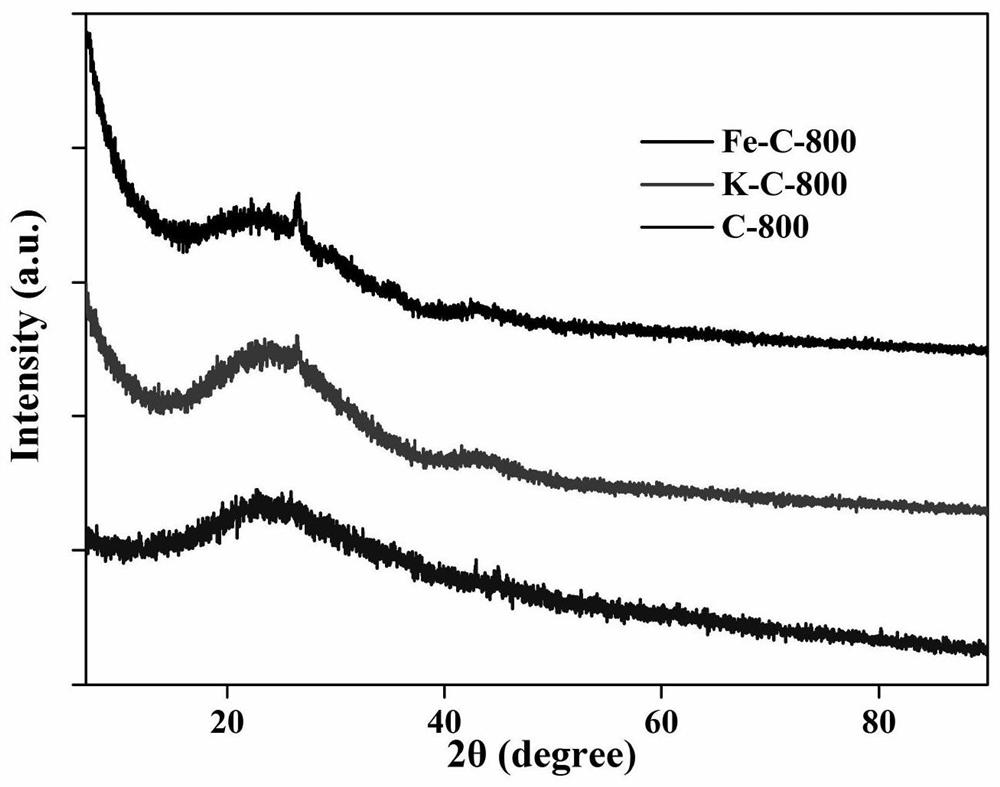

Embodiment 1

[0052] The main experimental drugs of the present invention include: potassium ferrate (VI), boric acid, 1-methyl-2-pyrrolidone, potassium hydroxide, polyvinylidene fluoride, hydrochloric acid, sulfuric acid, polyvinyl alcohol, graphite paper, deionized water, Acetylene black, thiol protease, sodium thiocyanate, potassium thiocyanate, phenol, butanol, novolac resin containing polyethylene glycol; main instruments include electronic analytical balance, magnetic stirrer, electric heating constant temperature drying oven, tube resistance Furnace, plasma cleaner, vacuum filter, electrochemical workstation, X-ray diffractometer (XRD), scanning electron microscope, Raman spectrometer.

[0053] A preparation method of bean dregs-based nitrogen-boron co-doped porous carbon material is a one-step impregnation carbonization activation method, comprising the following steps:

[0054] (1) The bean dregs are boiled for 1 hour, fermented, washed and freeze-dried to form dry bean dregs, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com